Guest Opinion: Billy Godbold, COMP Cams’ Valvetrain Engineering Group Manager

Balancing Drivability and Performance

Have you ever called a cam company or filled out some form that was supposed to help you pick out your “perfect” camshaft? You know the one: that magical stick that would give you 6-second passes in the quarter, 40 MPG, the track record at the Nürburgring, and an idle that purred like a kitten when you picked up a date but would make John Force nod in approval as it loped through the pits like a Top Fuel car. As we grew up, we learned some of those things were just impossible to achieve in a single build. But did you ever wonder how the Tech Department at COMP Cams helps someone get as close as possible to the right cam for the application, when the goals are realistic?

Everything starts with understanding why the cam matters so much to the performance of the engine. Of the four valve timing events, the most important to performance is intake closing. You want to close the intake with the piston moving upward during the compression stroke — just as the pressure in the chamber builds to the point that (even with wave tuning) the inlet flow direction changes from in, toward the chamber, to out, back toward the intake manifold. Sounds simple, right? The difficult part is that the angle this occurs gets later and later as RPM increases.

All Variable Valve Timing systems are tuned to try to chase that flow reversion point by moving intake closing, but with most fixed systems, you are kind of stuck with one intake closing point. Hence, it is only perfect at one RPM, compromising performance more and more as you move away from that optimum engine speed.

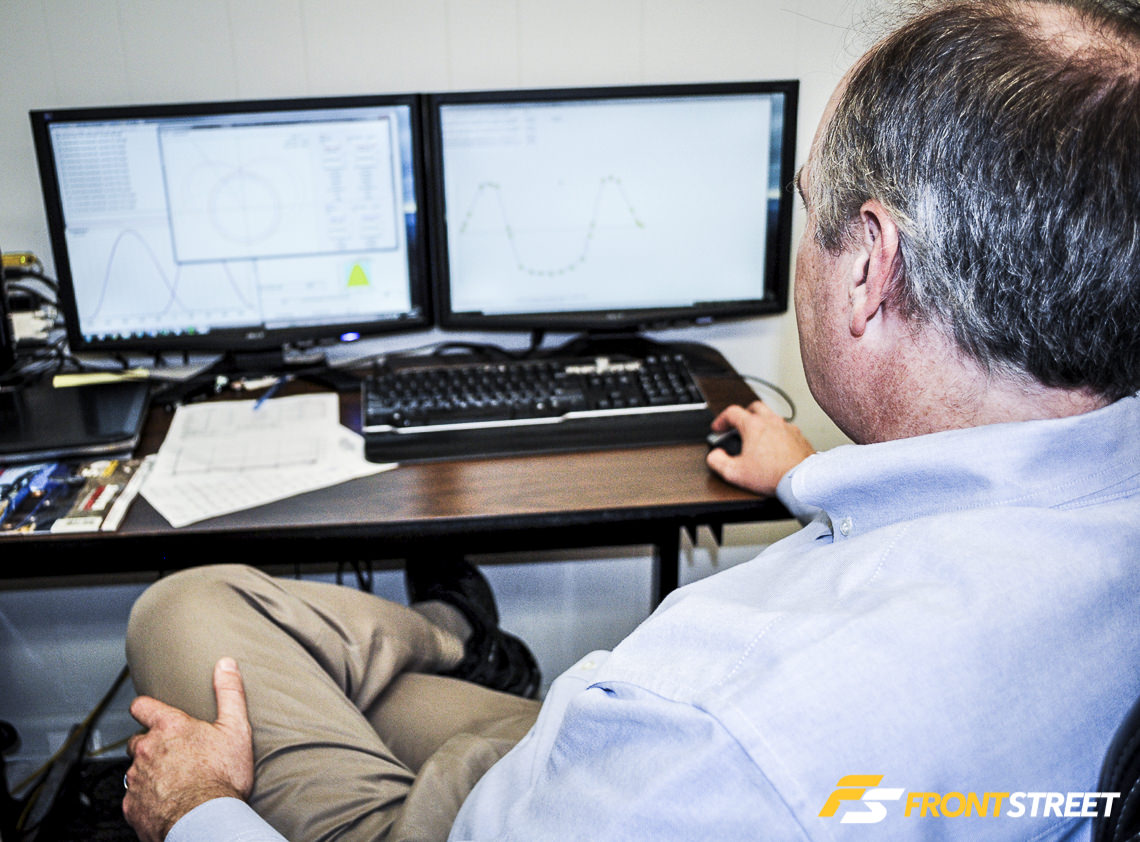

Billy Godbold hard at work creating camshaft profiles for COMP Cams.

Thus, the first question someone will ask when trying to help you select the best cam will always deal with your engine configuration and operating RPM. If you think about that intake port flow, it is easy to see a smaller cross-section port will have more velocity and momentum, needing a later closing event for the same RPM level. Likewise, larger displacement will make a larger port seem small.

The technician will ask about the intake manifold in order to understand the relative length, as longer runners will have a stronger and later wave tuning point, and that flow change will happen later than with a short runner. Also, smaller considerations like rod to stroke ratio or even valve seat angle in a very racy head can play an effect on the performance of a particular set of camshaft dimensions. Once the basics of the entire port configuration is understood and referenced to the cylinder displacement (factoring in bore to stroke and rod to stroke ratio), the technician should have a really good idea of where the intake needs to close for a given RPM.

After the round of engine questions, you will probably be asked about the vehicle. My teenage response was always, “Why do you care whether it is going in a dragster or a combine?” The biggest reason for these questions? The technician needs to know the real operating range of the engine. You may think the engine is going to run 4,500 to 7,500 rpm, but if you have a heavy vehicle with a stock converter, automatic transmission, large tires and stock gear ratios, you can’t choose the intake closing point where the engine makes near zero torque at 2,500 rpm.

Regardless of everything else, any vehicle you want to enjoy on the street has to have some torque to get it moving and can’t stumble around as it drops RPM on each shift. Heavy cars or boats will load the engine differently, too.

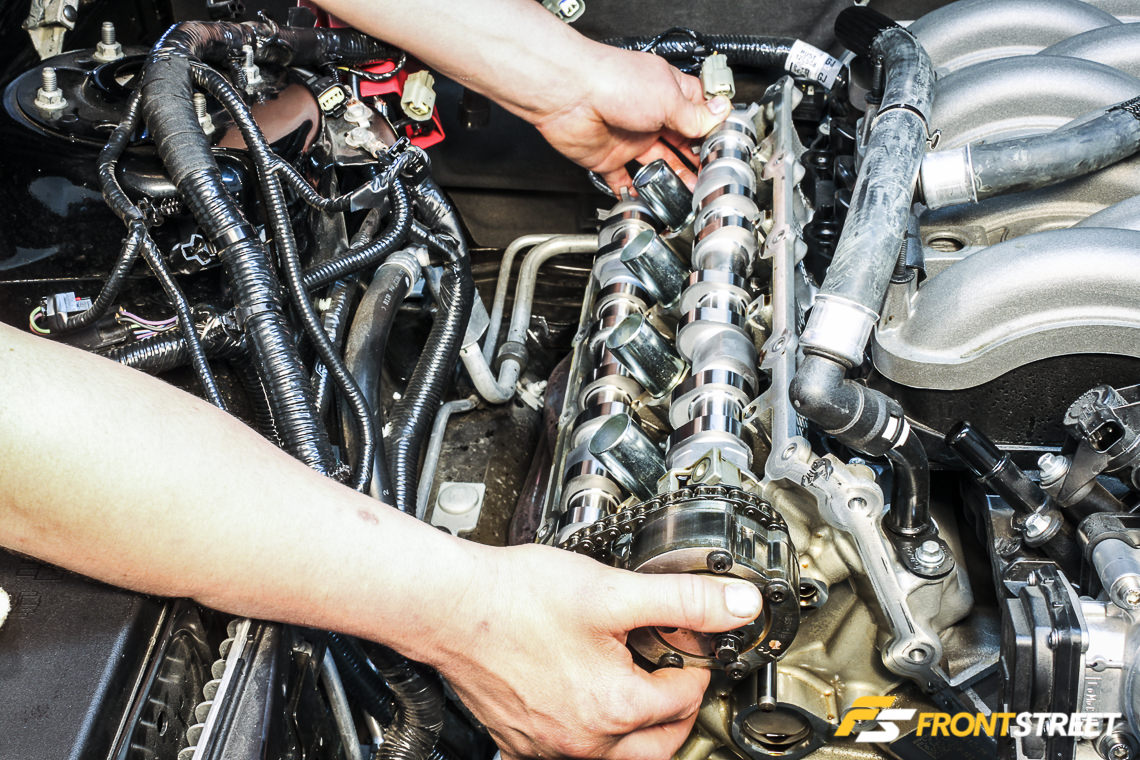

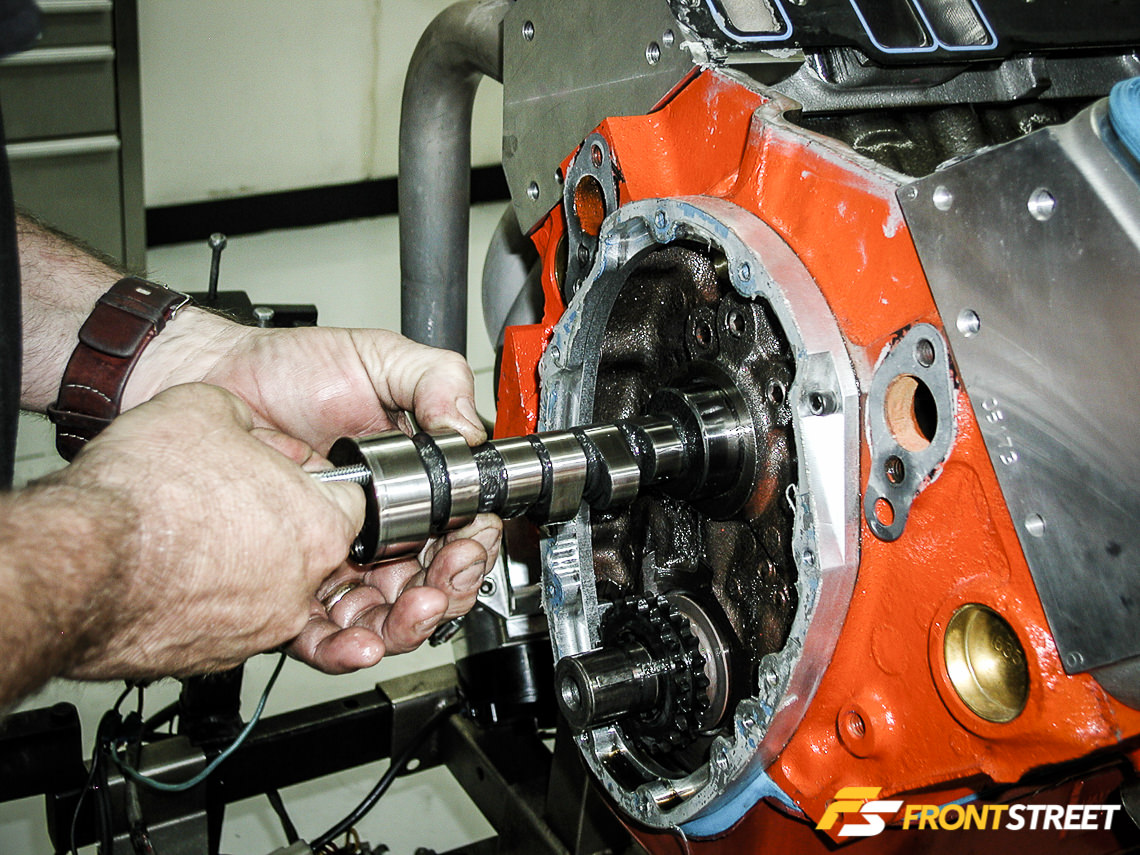

Various steps in the camshaft machining process.

Exhaust opening is very much like intake closing (just not quite as significant until very high RPM), and the technician will be balancing both timing events together; they’ll need some idea of the exhaust/Intake flow percentage of the cylinder head and your exhaust system configuration. So, make sure you share flow data — if you have it — and anything about header length and collector configuration, or anything weird in the exhaust.

While intake closing and exhaust opening are the two most important valve events in terms of tuning for a given RPM range, they are not the most difficult to optimize for street and track use engines. The big hurdle here is always optimizing the overlap triangle.

In 99-percent of race engines, the intake and exhaust systems are tuned to work together almost perfectly in their tight-operating RPM range. With wave tuning, it is common to see well over 110 percent volumetric efficiency, meaning a 350 cubic-inch-displacement V8 will move well over 770 cubic inches of air through the system every two crank revolutions. On these tuned engines, you really need more overlap so the intake systems sees the negative pressure wave from the exhaust — and that only happens with sufficient overlap.

However, in race engines, you also tend to want both a small chamber volume (for compression) and a very centered and uniform combustion chamber. Deep piston valve reliefs actually can be a bigger detriment to efficiency than the increased overlap would be beneficial for airflow. All this means the “how much overlap” answer in professional race engines is generally as much as would fit without carving too much from the piston. Hence the “cool” race engine stumble at idle that we all relate to big power.

For a dual-use vehicle, the technician has to pay extremely close attention to how increased overlap is going to change not only piston to valve clearance, but also idle character, vacuum accessories and the performance of any engine electronic controls. Also, we go back full circle to the actual operating RPM. While more overlap might be good for performance as low as 3,500 rpm, it can make throttle response poor at 2,200 rpm while rolling onto the throttle on the expressway, or at vehicle launch compromised without either using more clutch or installing a higher stall speed converter.

The big picture: the whole vehicle has to be viewed as a system to choose the correct camshaft. Clear, honest goals need to be set before undertaking modifications. By working with a partner you can trust (and we hope that is COMP Cams), you can choose the right cam for excellent performance on the track while still meeting or exceeding expectations during your commute or weekend drives on the street.