- 2015+ Volkswagen Golf TSI/GTI/R models are known as the MK7 chassis.

- Built on VW’s popular MQB platform, these Golfs share parts between the Jetta, Tiguan, etc.

- Mishimoto’s performance radiator solution remedies the factory shortcomings by changing construction material and expanding volume.

If you’re familiar with either the Volkswagen Golf, the marque’s popular MQB platform, or German engineering in general, then you’re already on the right track to understanding the necessity of today’s article. For the remainder of you, Volkswagen utilizes a modular platform named the MQB that shares parts and assembly between the Golf TSI, the MK7 Jetta, the Tiguan, and a few other front-engine FWD and AWD models. It’s like multi-tasking from a manufacturing standpoint with one platform used to encompass them all. Within that, there are pros and cons. A pro is cost savings for the company to create the same parts for multiple chassis simultaneously. Meanwhile, a massive con is the “Jack of all trades, master of none” capabilities that some items in this equation possess, namely the radiator.

The topic of today’s discussion is the primary radiator on the 2015+ (MK7) Volkswagen Golf TSI/GTI/R and its shortcomings of sufficiently cooling. Luckily, one company that doesn’t do “one size fits all” is Mishimoto, so when its team of performance gurus and engineers got their hands on the MK7, they analyzed and conquered, and we’re here to display the results.

FIRST IMPRESSIONS (STOCK)

Depending on the year and transmission of a MK7, almost every mechanical system in the engine bay relies on the primary radiator keeping the temperatures low. The heat reduction in its cooling circuit even transfers benefits through the oiling system. For later model dual-clutch-equipped vehicles, VW created an independent cooling system instead of branching off the central unit but then reduced the core thickness of the primary radiator.

The radiator is the last recipient of cool, fresh air and is a relatively tight fit as expected with a German engine bay. Surrounded by other heat exchangers, the radiator has to work much harder to dissipate its temperature.

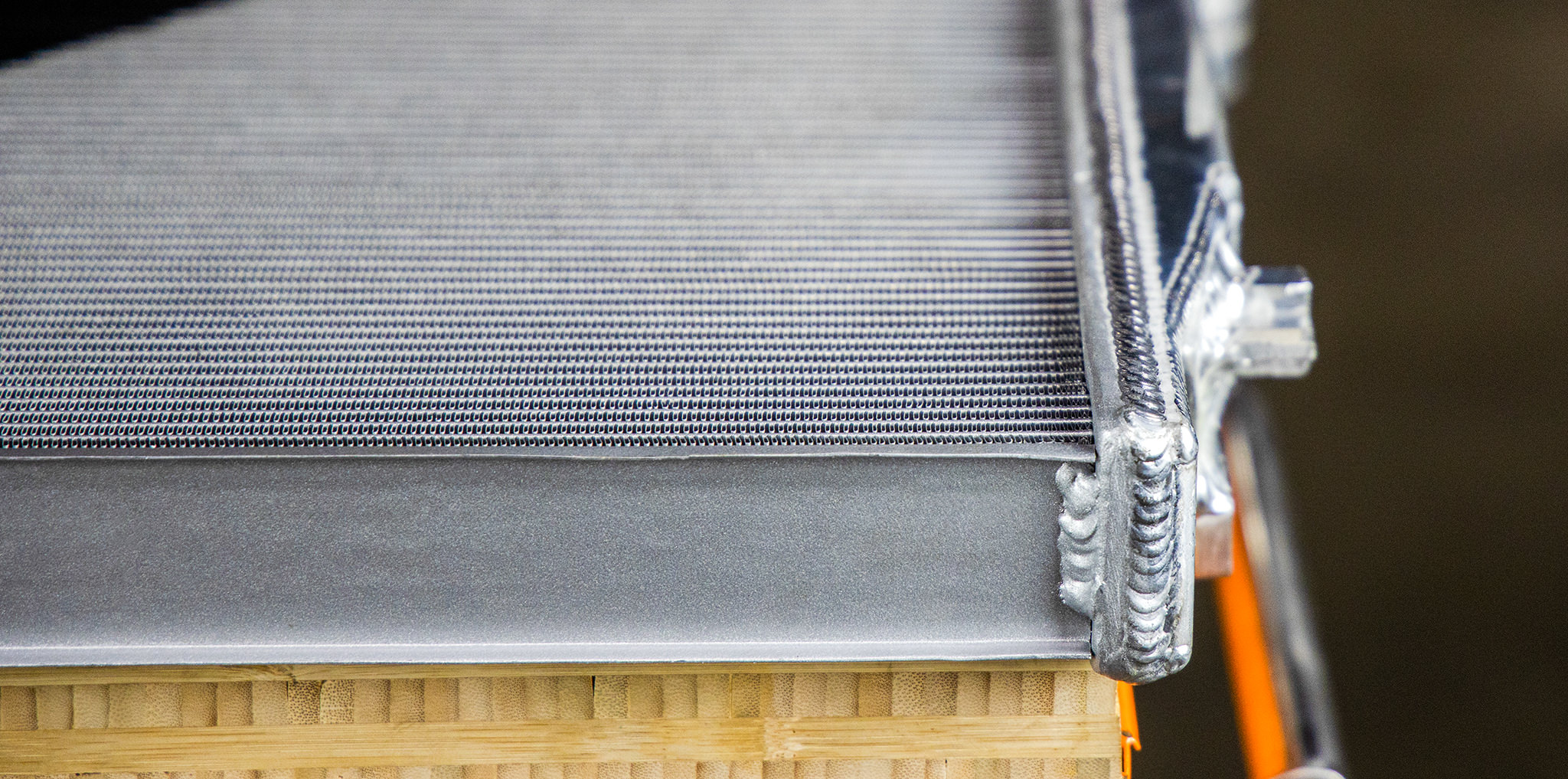

Its calculated core size is crimped to plastic end tanks in true OEM fashion. Much like the MQB platform itself, the use of plastic end tanks is inexpensive for large-scale production. The concerns arise when this plastic is exposed to constantly changing extreme temperatures, becomes brittle, and eventually cracks.

DESIGNING THE SOLUTION

As mentioned above, there are space constraints whenever developing a cooling solution for German vehicles. They sure like to efficiently use the space provided (aka cram them into tight spaces and build up around them), drastically limiting any available space for an upgrade.

However, increasing core thickness and volume are some of the aspects that aid in gaining performance. With the stock core measuring 27mm in thickness, the majority of the increase is in width. Mishimoto can’t just bump up the dimensions everywhere, though, for two reasons. First, too thick of a core will hurt the dissipation rate and ability. Secondly, Mishi is a one-stop-shop for various performance cooling devices, and it needs to optimize (enlarge) the intercoolers, too. A 15mm addition to the primary radiator core was the ticket, providing cooling relief to all variants of the Golf without disturbing its abilities.

Aluminum end tanks will replace the failure-prone plastic components fitted on the factory unit. This conversion to aluminum also increases the end tanks’ coolant capacity while retaining the same silhouette (as not to affect the fitment). Mounting locations will remain the same, and the factory-designed quick disconnect fittings made it to the final design to avoid hose factory replacement.

SINGLE VS. TRIPLE-PASS FLOW PATTERN

Show of hands, who knew there were different flow patterns for radiators? (🙋♂️) Sometimes coolant passages with multi-stage routing will lower temps that much more. Picture all coolant passing from one side to the other simultaneously (single-pass) versus utilizing an S-shaped maze that opens the passages up to a fraction of the fins on three different occasions (triple-pass). In this particular instance, Mishimoto’s fabricator welded dividers to create the S-shape. Ultimately, there was no noticeable performance increase utilizing the triple-pass flow pattern. The team cited pump speed, pressure drop, and airspeed as a few factors that affected the performance of the triple-pass layout. Keeping the coolant in the radiator longer can be detrimental, as Mishimoto experienced while testing the MK7. Because of these factors, Mishi chose the single-pass design over the similarly yielding triple-pass.

FINAL CONSTRUCTION

Here it is! The cooling experts ditched the plastic tanks and fittings found on the factory piece in favor of a more durable solution. From core to end tank and mounting points, aluminum is the element of choice — the company even CNC machined the inlet and outlet for a perfect fit to the factory VW quick-disconnect hoses. Strutted coolant tubes help maintain rigidity and reduce flex inside, which prevents blockages, crimped tubes, or leaks.

Expanding the core by 15mm improved the total thickness to 42mm with a 56-percent increase in core volume overall. The higher volume and fluid capacity help enhance thermal management and keep unruly coolant temperatures more consistent — a vital statistic if you ever plan to have an exciting day at the track. Mishimoto increased external fin surface area by 76-percent by utilizing louvered fins with a 4.5mm pitch.

TESTING, TESTING…

42mm larger this, and 56-percent better that, with 76-percent improvement overall, etc. It all sounds great in theory but can the new aluminum solution back it up in real-time? To test it in some extremely harsh continuous load conditions, the team at Mishimoto strapped a MK7 Golf R to their in-house Dynapacks. From there, they calibrate the Dynapacks to hold the vehicle at 3200RPM while at wide-open-throttle (WOT), hopefully exceeding the harshest conditions this Golf R’s cooling system will ever experience.

Comparing the stock item to the single-pass Mishimoto performance radiator resulted as you would expect — the all-aluminum performance radiator performed better. How much better? It registered 5ºF cooler during testing, which doesn’t sound like a massive improvement, but it is. In the world of coolant temperatures, five degrees on the track can be the difference between a safe and problematic threshold (especially when considering touchy sensors in new cars). By reducing the global coolant temperatures in this multi-tasking radiator’s system, the benefits extend into nearby intercooler temperatures and even engine oil temperatures.

In the end, it’s not the worst thing that the MK7’s radiator ties into so many systems. Once a performance variant (like the one from Mishimoto) lowers the coolant temperatures, the benefits stretch further. That being said, switching out the one-size-fits-all MQB-based factory piece is a must if aggressive driving conditions are on the docket. You’ll be glad that you did.