From an inauspicious boyhood growing up on the family farm to today’s career as the proprietor of Firepunk Diesel, Lavon Miller knows one thing – to outwork everyone else to achieve his goals. Everyone has to start somewhere, and since Miller wasn’t born with the innate knowledge of turbocharger A/R ratios and how they affect performance, or how to get a Dodge 48RE transmission to stay alive at 2,000-plus wheel horsepower levels, he had to learn.

The story starts well before that, as the aforementioned Ohio farm kid wanted a quick vehicle, but couldn’t afford both a work truck and a Corvette at the same time. Something had to give, so securing the work truck took precedence.

“I needed a diesel truck for my job – we were doing general construction and concrete work. We needed to haul trailers and tow a man-lift around to do the job. My dad bought a 2000, and I bought a 2001 Dodge,” says Miller.

“But boys will be boys. I bought my truck on January 1, 2004, and by December of that year I had injectors, an Edge Comp box, twin-turbos, and some other goodies. I needed my truck for work every day, so when I’d break something, I’d stay up that night until it was fixed so I could have it for work the following morning.”

Since he was abusing the truck to within an inch of its life on a regular basis, he found himself repairing the truck on a regular basis as well. Ten years ago, before the all-inclusive world of Facebook overtook the internet, enthusiast forums were all the rage as a means to share information with like-minded people from all over the country – and the globe.

It was within this world that Miller found his home.

“I invested hours and hours learning everything I could about it, and I went from not knowing much about diesels altogether to knowing quite a bit within a year’s time. We had a pretty good background in mechanical things; my grandpa had a lot of fabrication skills, and we had enough tools there to be dangerous, but we were not conventional fabricators by any means,” he says.

By putting together all of these elements, Miller learned how to make enough horsepower to break a lot of parts over the next several years. With the construction and concrete businesses seasonal in central Ohio, Miller needed to keep himself occupied during the long, cold winters and rainy days.

So what did he do? Started working on trucks for other people, by using the blueprint and knowledge he’d gained working on his own rig to help his friends and other local diesel enthusiasts make big power with their hay-haulers.

“We’d all go to the dragstrip on Friday nights to have fun. We started Firepunk.com as a website to host pictures and videos of our builds, and drag races and burnouts and whatever fun stuff we did,” says Miller.

“My friend Brandon Miller – whose twin-turbo truck I modeled a lot of my original build after and is still involved with Firepunk Engineering – is the one who gets credit for starting the Firepunk website. We had also saved the domain name for Firepunk Diesel just in case we turned it into a business. But for the first five years, we just used Firepunk.com, and post links to the stuff on forums and social media,” says Miller.

In that way, he was well ahead of his time when it comes to leveraging the World Wide Web to build a business that didn’t even exist yet. By creating a high level of brand recognition, Miller and his friends were able to develop a following before the shop even became a reality.

By Spring of 2010, he realized that there was enough work for him to switch gears, so he sold off the concrete contracts to another business and began working on trucks full-time, by himself. One year later he had four guys working for him, and now in 2016 there are 13 employees of Firepunk Diesel.

“It’s a hobby that turned into a business – I put just about all my spare time into it; instead of going out and partying and doing crazy stuff I stayed at home and read the forums and the internet to figure out how to make my truck faster. That consumed my teenage years and my early 20s – being self-taught was the main thing behind it,” Miller says.

Today, Firepunk Diesel is one of the go-to Cummins shops on the planet; Miller says the shop’s one-day-turnaround transmission swap program has them building upwards of 50 transmissions per month. There are four employees in the transmission room building 47 and 48RE gearboxes, and four employees in the shop making customer’s trucks quicker.

Not only do they work hard on the customer vehicles in the shop, they’re all enthusiasts – when the Firepunk Diesel team goes to a diesel drag race, they take between 6 and 8 trucks every single time. This level of involvement results in gained knowledge that can’t be discovered anywhere but under the extreme stresses of the track. Since they race their own vehicles, but are also there to provide the support for Miller’s Pro Street race truck.

“That’s why I think we’re so successful; when guys are here in the shop working on customer’s trucks, they’re not just doing their job. They’re interested in diesel performance. They can make recommendations based on experience. I can turn a customer loose to any one of my guys in the shop and they can give recommendations to get the customer to the next step – and that’s because they have an interest in diesel performance as a whole,” says Miller.

The research and development process has continued with the truck you see here, Miller’s 2006 Dodge Ram 2500 4×4 regular-cab that Miller built with two purposes in mind. He was racing regularly in the Outlaw Diesel Super Series’ 10.50 Index class, where he won the points chase in 2015 with a four-wheel-drive quad-cab pickup; the truck ran 9.80s at 140-plus at full weight, which was well over 7,900 pounds. Miller kept watching the Pro Street class and wondering whether he could put his quad-cab powertrain into a lightweight standard-cab truck and be competitive, but felt challenged by some of the details.

“With a young business and as fast as we’re growing, it takes a lot of revenue to keep cash flow going. I wasn’t in a place where I was willing to spend the money that it took to build a Pro Street truck until we found out we weren’t eligible to go back to the Diesel Power Challenge – you can only win that event twice. At the same time, the Ultimate Callout Challenge came about. I felt the quad-cab would be too heavy to be competitive at the UCC, and there would be more Pro Street-level trucks ready for UCC,” says Miller.

The truck in dyno-rolling trim

So the Firepunk team sat down to talk through the concerns, made the decision to go all-out on the new project, and sent the check off to the UCC for inclusion into the event on a November Monday. By Thursday Miller was on a plane to Tulsa to pick the truck up and drive it back to the shop. The initial plan was to take the big-power drivetrain from the quad-cab truck and adapt it to the smaller, lighter platform, but once they got the new truck onto the scales, it was only 1,000 pounds lighter than the big truck.

And that’s when the plans went wild. Miller tapped into the expertise of some of his sponsors – Exergy, Engineered Turbo, and engine builder D&J Precision Machine – to determine what each thought it would take to win the Ultimate Callout Challenge. Horsepower goals, elapsed time, sled-pull setup; all were on the table, and the truck was built on paper. The truck was torn down in the first week of December, and the Firepunk team was off to the races – literally.

Lyn MIller (Right) and Lavon MIller (Center)

“My brother Lyn is our fabricator. That was all he did all winter, was fabricate the chassis for the truck. He did all of the research, figured out the do’s and don’ts. We went into this Pro Street truck project uneducated as far as what it takes to build a chassis that’s going to hook up. There are a lot of drag racers that can give you good information, but very few of them can give you good information how to set up a four-wheel-drive chassis. You need the weight transfer, but you need to keep the front tires planted because those are also driving the truck. That’s where Lyn stepped in to make sure we started off with a good platform,” says Miller.

There’s no doubt the effort paid off, as the very first time the Firepunk Pro Street machine went down a quarter-mile track in preparation for the Ultimate Callout Challenge, Miller stopped the clocks with an insane 8.27 at 166 mph.

“We were hoping to hit 8.50s with the truck at some point, and went three-tenths under our goal the first time on a quarter-mile track,” says Miller.

Miller’s winning dragstrip run from the Ultimate Callout Challenge

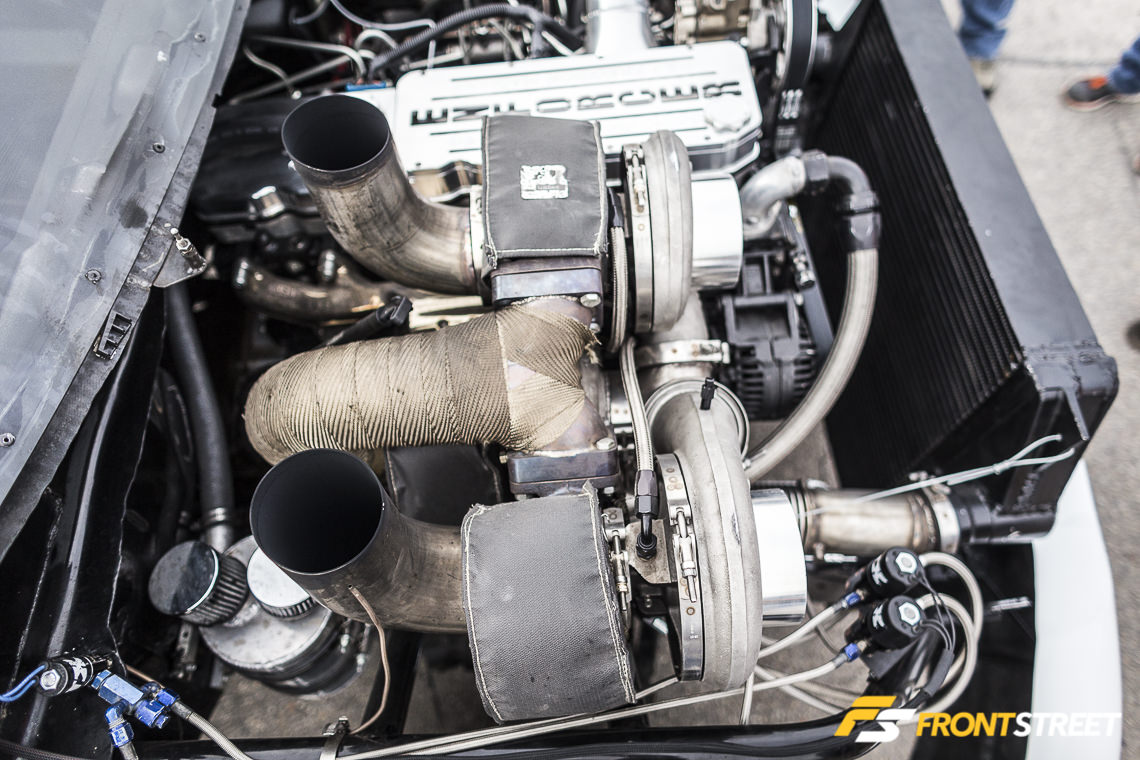

The 4,540-pound truck relies on the Lyn Miller-built backhalf/ladder-bar chassis and a deckplated 6.7-liter Cummins engine built by D&J Precision Machine. The use of the deckplate means that the D&J billet connecting rods can measure one inch longer than stock. Billet D&J FSR pistons, a Hamilton roller camshaft and Stage 3 D&J cylinder head combine with the custom intake manifold, triple Engineered Turbo S400 turbochargers, and a Stainless Diesel exhaust manifold to finish off the majority of the engine components. Fueling is handled by three 12mm Stroker CP3 pumps and 500%-over injectors crafted by Exergy Performance, and boost control is handled by a pair of Turbosmart’s HyperGate 45HP wastegates. The Firepunk Diesel team relies on an EFI Live fuel-injection system tuned in-house to manage the power.

As one might expect, one of Firepunk’s Competition Stage 3 48RE transmissions is onboard, with power running through one of Diesel Performance Converters’ quad-disc torque converters. The team switches between Yukon 3.42:1 gears for drag racing and 4.56:1 gears for sled pulling action, while TBM brakes sit at all four corners to slow the big truck down after a monster strip pass. Afco Racing double-adjustable coilover shocks provide all the adjustment the team needs to adapt to changing track conditions. And weight reduction was a priority with this build –a GTS Fiberglass front bumper, front clip, doors, and bedsides were installed to reduce unnecessary tonnage.

The point of the build was to create a truck to win the 2016 Ultimate Callout Challenge – a task achieved. Pro Street truck racing was secondary to the plan, but they’re also currently leading the Pro Street points chase in the Outlaw Diesel Super Series for 2016.

The more important plan?

“The foundation of our business has always been keeping our priorities straight. Our customers make the world go ‘round, and I always say ‘relationships over money’. If a customer has a problem, we’re going to take care of them,” says Miller.

That’s how business should be done.