Drag racing isn’t easy; winning at the highest levels of the sport takes a supreme level of dedication, perseverance, teamwork—and a large helping of discretionary funds. Competition is difficult, and there are many racers who have superior talent not only behind the wheel but also with respect to sorting out the mechanical bits which allow the racecar to perform efficiently on race day. Radial-tire classes like X275—the pinnacle of small-tire racing in today’s racing landscape—attract the best of the best, such as Ryan Milliken, owner of Hardway Performance Solutions. Even if you’re a fan of this type of racing, you may have no idea who Ryan Milliken is; we can assure you that if you don’t, you will soon.

Milliken’s fascination with motorsports germinated at an early age. In fact, to hear him tell it, it happened right about the same time he left diapers behind.

“You know the barefoot kids running around the pits at your local dragstrip or circle track nearly every weekend? That was me when I was four. I’ve been involved with racing motocross, circle track, jet skis, and drag racing for my entire life,” he says.

This obsession with all things motorized came about thanks to the man he calls “Mr. Horsepower”, his father, Michael Scott Milliken. Not surprisingly, his son Mikey is named after his father. The apple doesn’t fall far from the tree, as Mikey sits in the Nova—which he calls “Mikey’s race car”—and can occupy himself for hours sitting in the driver’s seat, yanking on the steering wheel, moving the shifter around and clicking buttons.

“My dad was a gearhead and horsepower junkie to the fullest; I looked up to him as a kid and still look up to him to this day. He passed away in 2012, but I know he’s watching what I’m doing from above. It was always his dream to have a hot rod shop (besides our garage) to play with race cars all day… I wish he was here today to see what we’ve got going on. I know he’d love it,” says Milliken.

Milliken brings an appeal to the class which stretches far beyond its current audience, into a market which is divorced almost entirely from the class in which he competes today. After separating from his position as a Technical Sergeant in the United States Air Force in 2012 and opening Hardway Performance Solutions with his wife, Leslie, Milliken quickly made a name for himself in the diesel performance truck category by specializing in the 6.7-liter Cummins engine platform. In short order, he became one of the go-to sources in this massive performance segment, but he still wasn’t satisfied with just being a diesel truck racer and decided to change things up a bit.

“My dad loved Chevy IIs, so naturally when I wanted to switch up from racing heavy-ass diesel trucks, the Chevy II is what I started looking for. I actually tried to buy back his Chevy IIs, but when I went to look at them I realized they weren’t even worth much as far as parts go, and it was better off to let them lay where they lie as they were too far gone. I found another Nova that had a restoration started on it and they quit right after the strip process, so it was basically a perfect carcass to start with. I scooped it up and did some work on it, went to PRI to do some shopping, and boom: I walked around the corner to see this car for sale in the TBM Brakes booth,” explains Milliken.

At the time, this ’66 Nova belonged to Mickey Tessneer from Mickey’s Chassis Works in Oklahoma, and as you might imagine, as the “chassis guy’s car” it was full of all sorts of little tricks and unique touches. It was christened the “Green Reaper” and featured a ProCharger-boosted big-block Chevy underhood.

“I know what I want, and when I make a decision I don’t hesitate. So in about 15 minutes of talking to Mickey, I knew I had to have this car. I ended up having my wife send a deposit check, and we worked out the rest between then and when I picked it up. I ended up trading in the Nova that I had started with, to Mickey, had the motor sold before I picked the car up and went two days before Christmas in 2016 to pick up the rolling chassis,” he says.

The car belonged to Tessneer for eight years, but was only raced for two before it was put up for sale and Milliken purchased it, with visions of radial-tire racing dancing in his head. With the shell brought home as a roller, he and teammate/crew chief/co-driver Daniel Pierce swapped the car into diesel trim in a matter of eight weeks and spent the entire 2017 season sorting the car out. They have a limited amount of time to play with it; not only does Milliken run Hardway Performance Solutions every day, he’s also the Managing Partner of Emerald Coast Dragway, an eighth-mile dragstrip in Holt, Florida.

Without Pierce’s involvement in this racing program, though, Milliken would be up the creek without a paddle.

“If it weren’t for him keeping it together, I wouldn’t be able to make a third of the races that we do, because my businesses and kids have me so insanely busy that I rarely have time to stop and smell the gear oil,” says Milliken.

The ’66 Nova’s 25.2-spec chassis wears a Smith Racing bolt-on front end setup with struts, a grand departure from the Nova’s original suspension arrangement. And as a card-carrying member of Leaf Spring Nation, Milliken does the dance on what could be considered an antiquated rear suspension design, although it uses state-of-the-art Calvert Racing split mono-leafs and Smith Racing’s Assassin traction bars to suspend the McNasty 9-inch housing built by Tessneer. The housing is filled with a Strange Engineering Ultra Case third member and 40-spline axles, and when combined with the Menscer Motorsports rear shocks and Santhuff front struts, the car is configured to perform as consistently as today’s modern stock suspension cars. As the only car competing at this level with this engine combination, it’s been quite the ride so far.

The process wasn’t simple; it never is.

See, Milliken says that the torque of the Cummins engine makes tuning this beast massively difficult, especially on such a small tire. Balancing the performance of the engine with the turbo and transmission combination, and getting them to work properly has proven to be frustrating and rewarding at the same time.

“Leaving on the transbrake with enough to get the turbo to go somewhere and a converter tight enough to make use of our super-short low RPM powerband means you have to get past the torque somehow. This usually means kicked tires and/or epic wheel stands. But we’ve managed to get really tricky with our converter setup, how we leave, how we apply nitrous, fuel quantity cuts as we get near our G meter peak, and converter dumps. Basically the first 60 to 80-feet of a pass is a near-perfectly-orchestrated song and dance. Once the g-meter noses over and the car settles out, we can turn on whatever we want and it’ll take it,” he shares.

You read that correctly… he mentioned applying nitrous, of which there are four stages and a potential 1,200 horsepower available via the system from Nitrous Outlet. In X275, if a competitor is using a six-cylinder engine, then nitrous is permitted as a second power-adder, and Milliken takes full advantage of that permission.

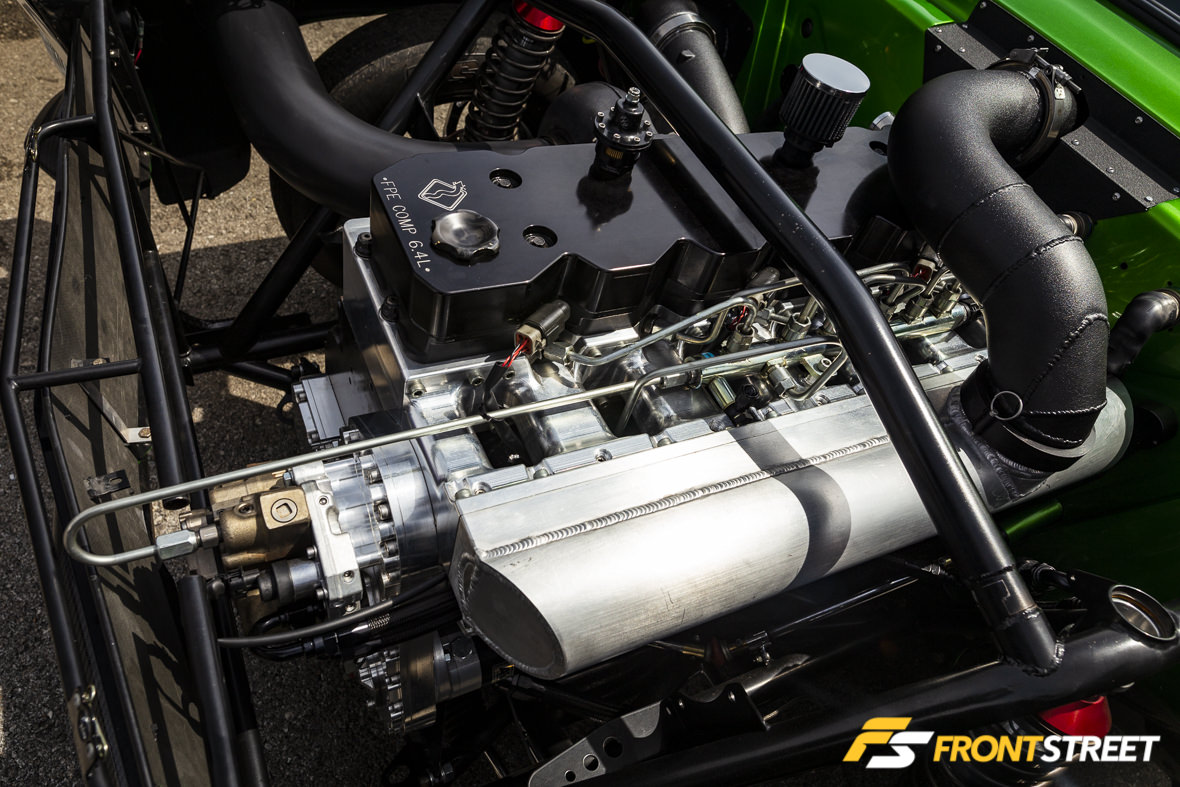

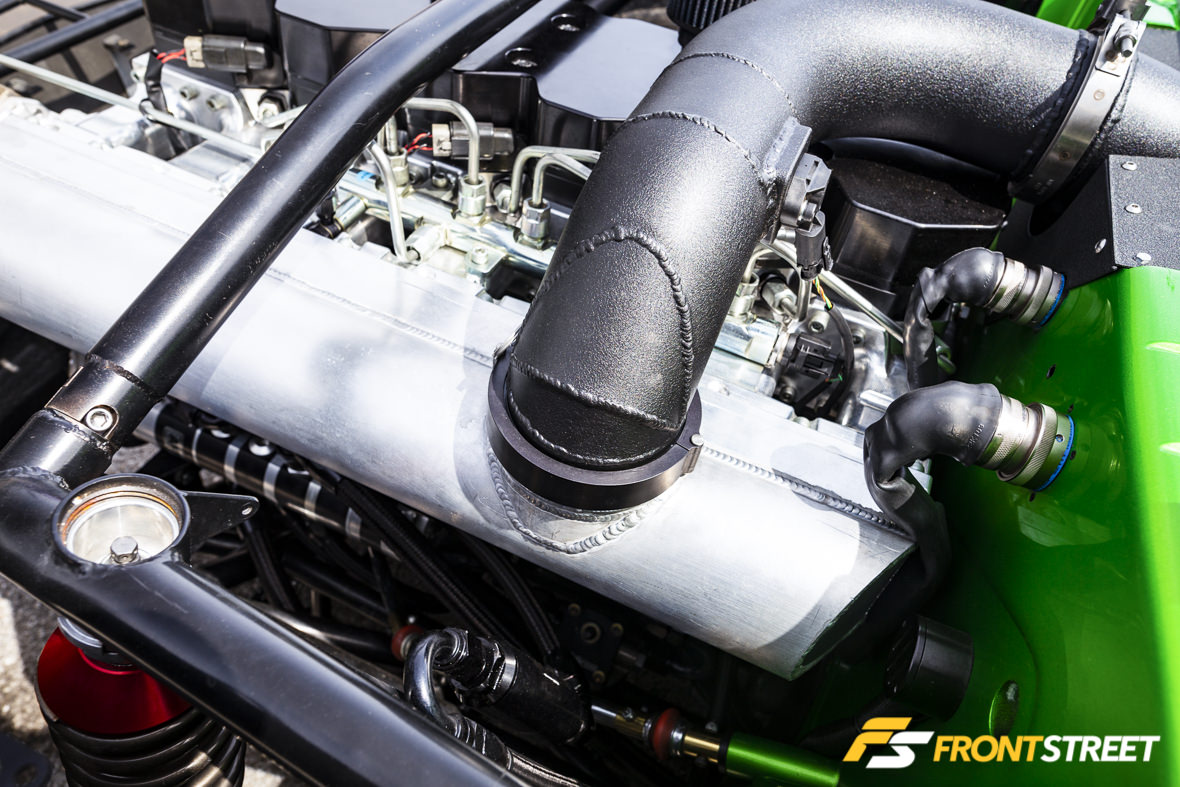

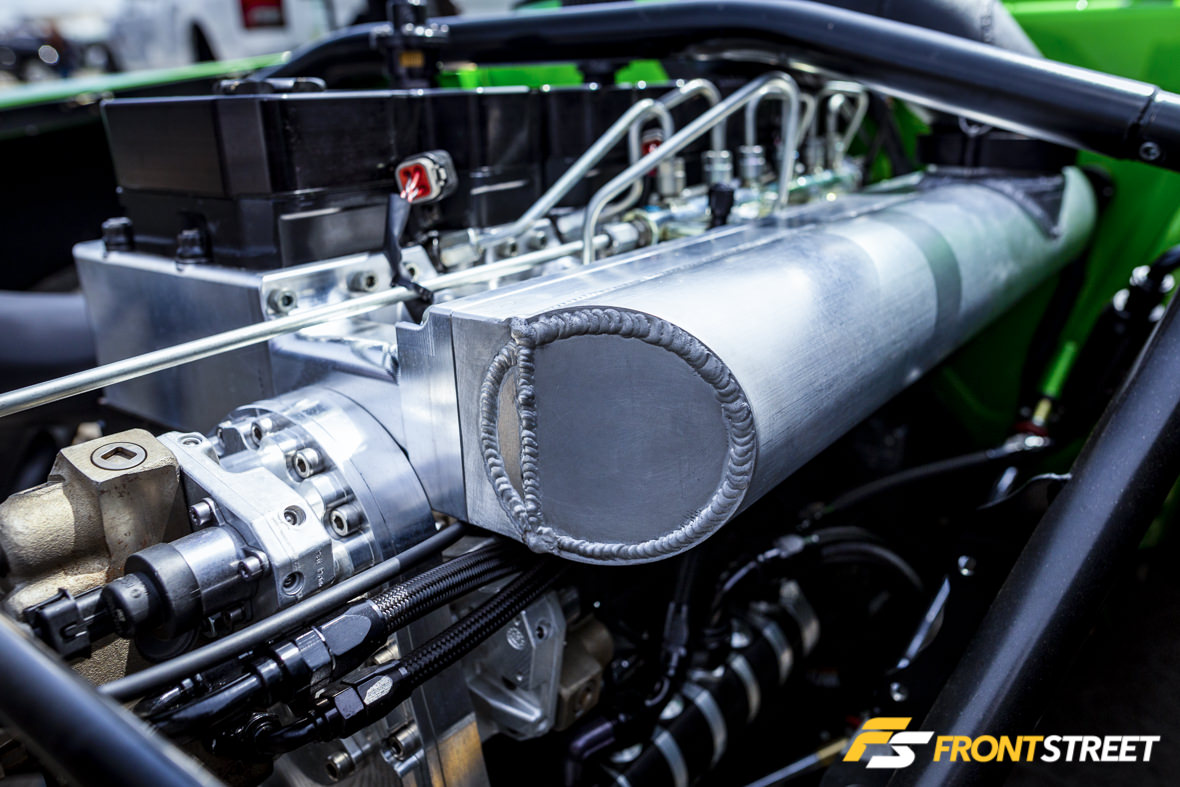

Speaking of the engine, Freedom Racing Engines out of Brownsburg, Indiana machined the pieces, which were assembled in-house at Hardway Performance Solutions by Pierce himself. The 6.8-liter inline-six-cylinder dry Cummins engine—there is no coolant—houses a stock Cummins crank, Wagler steel connecting rods, and 15.5:1 Diamond Racing pistons. When asked about the piston ring arrangement, Milliken simply said, ”Can’t talk about that”. Nor would he share details on the custom-ground Hamilton camshaft.

A billet cylinder head from Wagler is topped with Manton roller rockers and fed from a Wagler intake manifold, while the exhaust exits the head and runs straight into the turbo through a Stainless Diesel polished manifold. One of Garrett’s GTX5533R GenII 88mm turbochargers provides 75 psi boost pressure, which helps the engine to spin the dyno to 2,470 horsepower at 5,000 rpm and an estimated 3,000-plus lb-ft of torque at 3,000 rpm. Engine management is handled by an MS 15.1ECU from Bosch Motorsports.

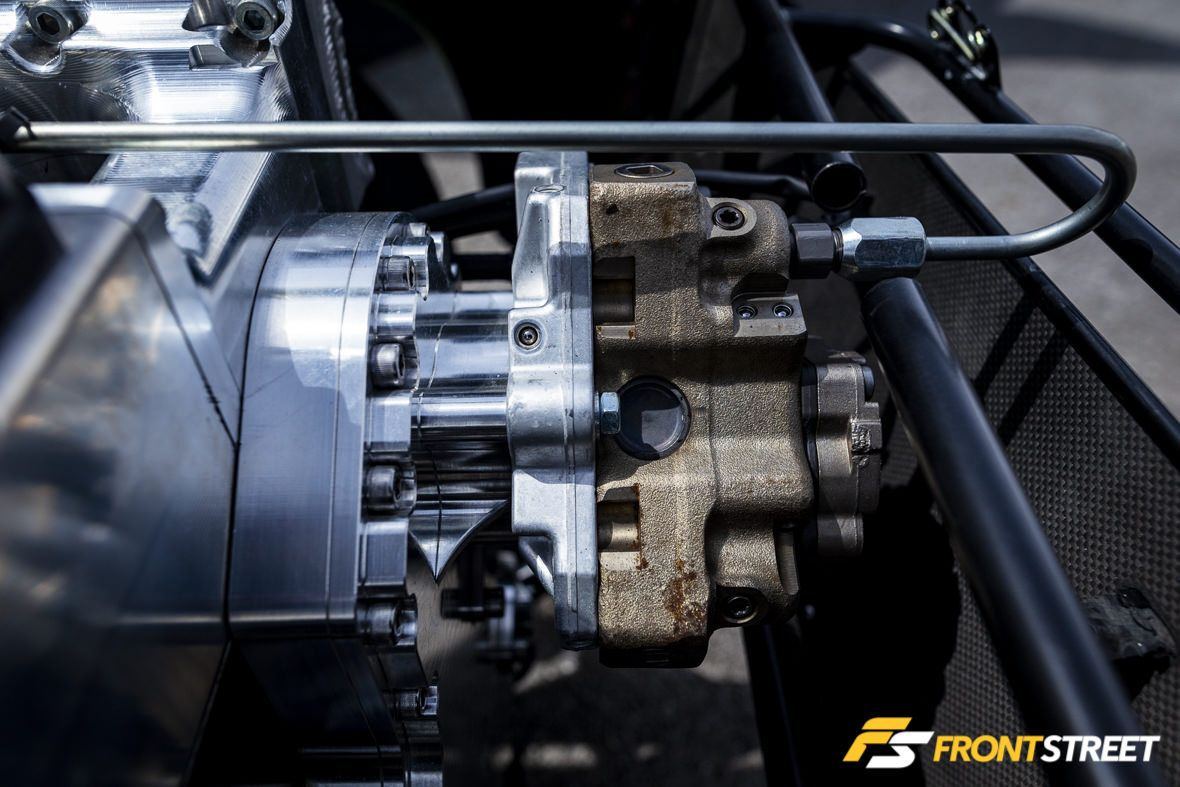

A stout Turbo400 with “all the mods” was built by Ron Wolverton and Ernie Davis at Suncoast Diesel and houses one of Suncoast’s 12.5-inch Pro Loc Zero Drag bolt-together lockup torque converters, which is required to transfer the massive power produced by this engine. Power runs through one of PST’s carbon fiber driveshafts.

Externally, the modifications are simple: carbon-fiber bumpers, hood, and a wing from Greg Shampine at Ultra-Carbon.

So far, they’ve been a best of 4.55 in the eighth-mile, achieved earlier this year at Lights Out, but the car is currently under the knife receiving a new fuel system and new wastegates. The plan? To run 170 mph at No Mercy 9, held September 26-30 at South Georgia Motorsports Park.

We asked Ryan perhaps the most important question we could think of—what would he do differently with this build, given the chance to do it all over again?

“Nothing. I love this car.”

So do we. And so does everyone else who sees it.