Pro Modified drag racing is all about big things: big wings, big blowers, big turbochargers, and big nitrous systems atop big engines combine with big tires and drivers with big personalities to create some of the most exciting racing action around. Despite a relatively short history—with beginnings stretching back to the mid-’80s—the Pro Modified class enjoys massive fan appeal. Originally contested at dragstrips all over the southeastern US, today Pro Mod is a featured class at many events all over the world and has several regional series dedicated to promoting its power and allure. The wide range of vehicles used in the class combines with all three power-adder combinations battling on the track with top speeds in excess of 200 mph in the eighth-mile (and 250 mph in the quarter) to capture even the most casual fan’s interest. Today, there are several Pro Mod racing sanctions around the world, with racers coming from far and wide to test their abilities against the best of the best.

One of those racers, Jonas Aleshire, has come onto the scene relatively recently, although he’s been behind the scenes as a chassis fabricator at Chris Duncan Race Cars, located in the bustling hamlet of Chandlerville, IL, population 553. Aleshire and master tuner/crew chief Chris Duncan—on a less-than-zero budget which sometimes runs on hopes and dreams—have been campaigning this supercharged 2006 Chevrolet Corvette in the Midwest Pro Mod Series, hitting other races when it fits into their schedule like the Yellowbullet Nationals, where I caught up with them to shoot these photos of the ‘Vette.

Aleshire, who has been a fan of muscle cars his whole life, subsequently developed a serious love for Pro Mods, and “it took off from there,” he says.

“This car was built in 2006 for a customer. It sat in a showroom for nine years until an opportunity was presented to utilize the chassis for competition,” says Aleshire. “It had been sitting since the day it was built, and had never seen the track before.”

The Corvette, which was fabricated by the team at CDRC, presented some growing pains for the team earlier this year when an engine failure could have ruined their season. But the self-funded team—which includes Duncan, Aleshire, and the rest of the guys from the shop—didn’t let that derail their plans; with a new engine underhood, they stepped up to the plate and turned in a win at the Midwest Pro Mod Series’ Throwdown at T-Town event held at Osage Raceway Park in Tulsa, Oklahoma.

When I contacted Jonas to write about the car, he warned me up front that he wouldn’t be able to give me some of the details I wanted; after all, competitive advantages cost money, and he didn’t want someone to gain an opportunity to get inside their racing program and pick out any nuggets of information.

With that said, I passed along our Front Street spec sheet and hoped for the best. There are certain questions on the spec sheet which detail the parts and pieces on the car, and we ask if certain components like antiroll bars exist… to which Jonas replied “Yes, ginormous”. Where we ask for gear ratio, he said “wouldn’t you like to know”, and it was with these answers in mind that I knew we didn’t really need to talk about those details in this feature. I did get a good laugh out of some of his responses, though, most of which can’t even be repeated in this family-friendly environment.

Despite what you might think about the difficulty of building and assembling a car of this caliber, Jonas and the CDRC team think it’s kind of simple.

“Nothing is challenging when you build these cars for a living. It’s is just time-consuming, but we have a passion for what we do,” he says.

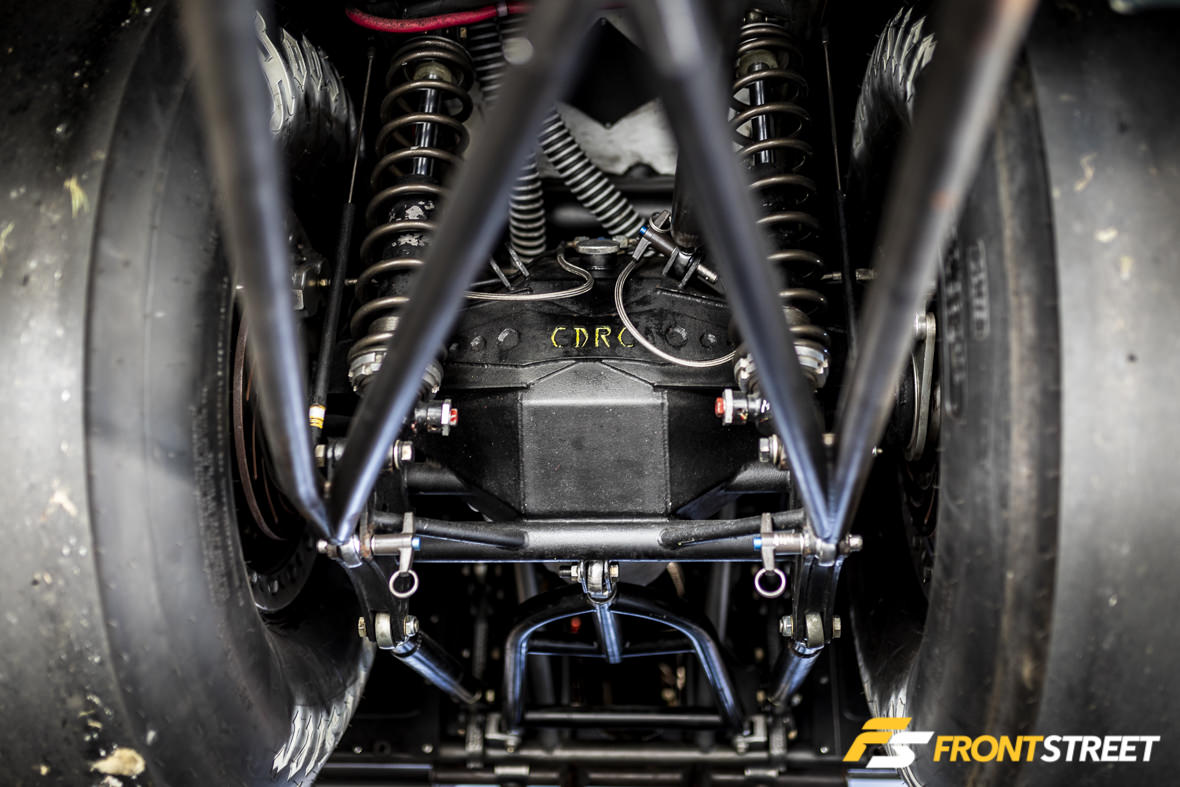

The chassis, built on one of the jigs at CDRC, has a Z06 Pro Mod body stretched over its flanks. Up front there is a strut-type suspension with Aerospace Components coilover struts (which are so old Jonas tells me they aren’t even made anymore) to go with Hypercoil springs, and Aerospace Components brakes. In the rear, one of CDRC’s four-link suspension setups uses the aforementioned anti-roll bar and a CDRC fabricated 9-inch rearend housing stuffed with Strange parts and old-school Santhuffs steel-body rear shocks. All of the suspension parts were fabricated in-house at CDRC, where Aleshire says simply, “we love what we do”. Hoosier tires roll on Sanders beadlocked rear wheels and Weld Racing V-Series front tires.

The car runs a 526 cubic-inch Brad Anderson Hemi engine machined by Hameetman Racing Engines, which was designed and assembled by fellow Pro Mod competitor Adam Flamholc in Florida. Jonas describes the camshaft as “lumpy”, with lots of duration and even more lift. It’s filled with R&R connecting rods, a Bryant crankshaft, and eight pistons wearing Line 2 Line coatings for durability. Mahle engine bearings keep everything spinning securely, while Noonan Hemi cylinder heads sit on top, fed by the overdriven PSI C-Rotor screw blower and mechanical fuel injection system. Custom CDRC zoomie headers get all the airflow out of the engine, and Racepak’s full sensor package is used to keep tabs on the car so Duncan and Aleshire can make track tuning calls.

Inside the car, a Lenco CS2 has been assembled by CDRC and uses one of Neal Chance’s “bad mofo” torque converters, with shifting duties handled by Aleshire. The car was wired and plumbed in-house at CDRC, whose team also includes Michael French, Bret Chaney, Trevor Ault, and Thomas Lohman.

Screw-blown Hemi cars are a different animal; Aleshire says that nitrous oxide is for dentists and electronic fuel injection is for turbocharged cars, and relies on Duncan’s championship-winning tuning experience to put the team in the right position on elimination day. Track-day support is handled by Todd Story, Josh Longshore, Lohman, and Mikel Clifton, each of whom have specific responsibilities to ensure that the car is capable of going rounds. And of course Jonas’ better half, Amber Sanders, who keeps the team running like a well-oiled machine whether she’s at the track or rooting from home.

Despite not receiving detailed answers to the questions regarding all of the components in the car, Jonas has helped us to see what’s under the skin of a competitive Pro Mod without giving away any advantages to the racers who occupy the opposite lane. And this car, which was simply sitting and looking pretty without a pass to its name, is definitely up to the task of appearing in the winner’s circle in one of the toughest racing classes around.