Businesses often start out with a single idea. “It would be great if we could solve X problem,” which is then refined and sorted out to become an actual product. About four years ago, that’s exactly what happened with Doug Cook, Andy Cook, Brian Jack, and the rest of the team over at Motion Raceworks. Although they had each been playing with their own race machines over the years and designing products for use on them, they had never manufactured a product for public consumption.

The decision to manufacture a turbo flange with mounting points to provide easy locating onto the chassis—a simple $1,000 investment—turned into a shelf of products in Doug’s bedroom, which over time turned into him quitting his sales job and moving the company into its first home in Davenport, Iowa. In 2019 they moved into a new, larger location in Dewitt, Iowa, and added several CNC machines to keep up with manufacturing demand. With a staff of 15 race enthusiasts—and growing—Motion Raceworks is at the forefront of developing unique products to solve elemental problems related to the construction of race cars.

When I first met Doug face-to-face earlier this year at the Sweet 16 2.0 race while shooting photos of Justin Cyrnek’s X275 car, I was impressed with his demeanor and enthusiasm for racing and the community in general. We had another chance to catch up a few weeks later at the Outlaw Street Car Reunion VI, and the wheels started turning about how I could get him involved with the party here at Front Street. I happened to catch a Facebook post he shared a couple of weeks later about how the company got started, and that little lightbulb clicked on over my head—One Question would be the perfect opportunity. I was curious about how they got here from there, and what spurred them to develop new products. So without further ado, let’s turn the mic over to Doug for his One Question.

How does Motion Raceworks/identify the need for a new product, and then subsequently bring it to market?

Doug Cook, Motion Raceworks : So this question is kind of the story of the beginning of Motion Raceworks. The simple answer is, we only care about solving issues that make building a project easier for people.

We had always raced locally and been driven by building our own cars, and a few others for friends each year. Each time we would build a car I would find myself standing around sometimes very frustrated saying “you know this part of the build is always a pain because nobody makes something like this.” or “It would sure make it easier if someone made this, or a kit for this.” This led to our first product, we added mounting ears to the side of a turbo flange, and we sold out in the first week. And then a few weeks later made another run, and it kept happening which made us think, maybe we can do this at scale.

That thought process has driven us to just put our ideas to paper to develop solutions and/or better products to solve real-world issues people building hotrods and racecars just like we did and still do. For instance, in 2016–17 we decided we were going to learn all about the Gen V [LT] platform. We invested the money, spent the hundreds of hours researching, failing and building so that we could get ahead of the “what the market needs” ideas as well as tech advice. We ended up setting the bar and making history with that car being the first person to really turn the wick up on the new direct-injected Gen V engines and go 7s. But what we learned and gained insight on was tons of knowledge which have driven and will drive that product line for years. For that reason, we have made it a point each year to build one or two cars, help other guys and friends who race, as well as listen to customers, like really listen when they call and talk to us. At this point, my and our mind naturally pays attention to all of these needs, concerns, complaints and from there we start the process.

After identifying a need, my next step will typically be to walk to my brother Andy’s office and tell him my idea or concept. About half the time he tells me I’m crazy, but we start working on prototypes and designs on paper. Once we get a game plan we will hand things off to one of our engineers for design. I will note that we are so fortunate to find other guys who love building cars and racing to work for us as engineers, which helps tremendously.

Today we are highly focused on scaling this innovation idea up both in speed and size. Just to be clear, we aren’t trying to build the best flowing head, or the newest EFI system, that just really doesn’t drive us as much. We simply want to solve everyday issues and improve on any product that we find shortcomings with. Motion Raceworks now has three in house engineers (which is a lot for a small company like ours). At all times of every week and month we have dozens of designs on the table and anywhere in the process. At this point one of our hardest things is having patience, both in telling people about “what’s next” and also getting things into a finished product so we can bring them to market.

We use a 3D printer nearly every day of the week, some days it runs wide open from lights-on ’til lights-off and runs through the night. This technology has really allowed us to rapidly innovate and put ideas into our hands to prove legitimacy and functionality without spending tons of capital.

With the design process, we have multiple informal meetings daily and weekly. We take those first drafts and redo them again and again until the function, aesthetic, and manufacturability fit ours—and the customer’s—needs and desires. You would be blown away at how many changes and reprints we make of even the simplest piece. It is our opinion that things need to be manufacturable, but look great as well!

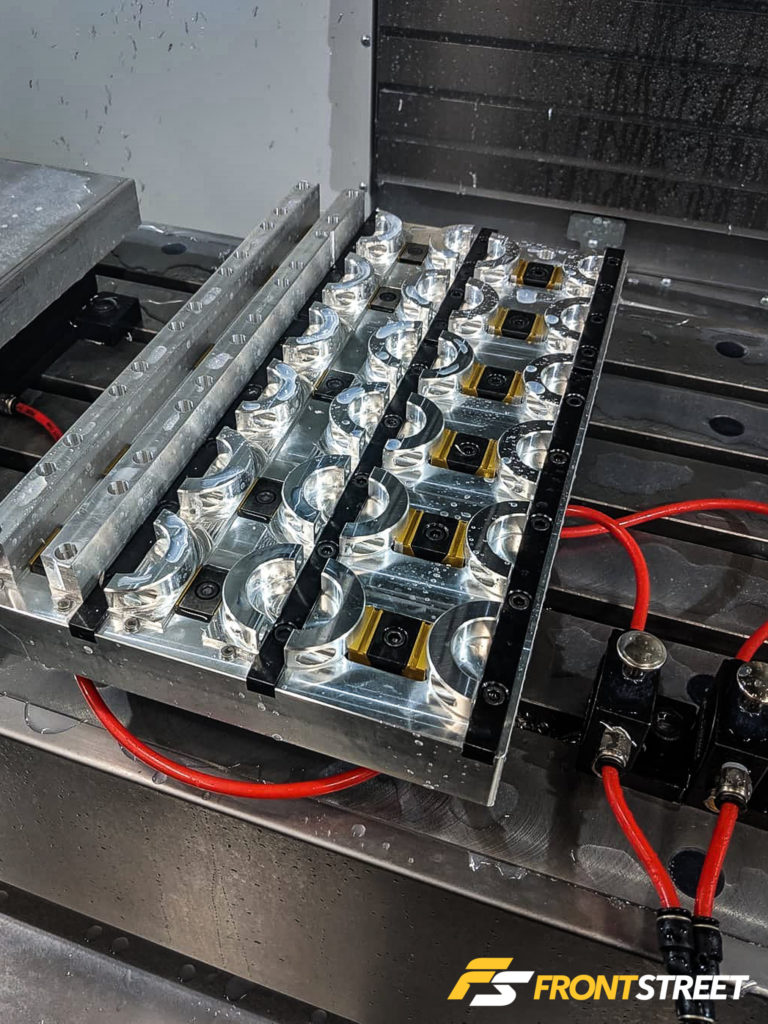

Last year we invested in our first Haas VF2 Vertical CNC Mill, and have since run out of capacity and added a VF4SS to the lineup. Once we get a 3D print completed we will typically carve out a billet piece, or if its sheet metal we will farm the work out to a supplier locally whom we work closely with. Even at this point we sometimes find things that are wrong with a part. Redo them, re-fixture. It’s not a romantic process, and you have to learn to swallow your pride sometimes and start over.

At this point in our company, we are focusing on producing everything in house, which is a big undertaking in and of itself. This will keep us from falling victim to other companies, suppliers, manufacturers failed deadlines and supply issues. Our end goal is to implement efficiency so that we can compete in the market against imported goods, but have Made in the USA quality. We have and continue to add machines, human capital, and a new facility to allow for all of this to happen.

The best part about our business, and it will always stay this way (so long as I am an owner), there is no CFO or accountant who can have bearing on our next move. We all love what we do and we aren’t driven by the bottom line or the safe bet in terms of new products.

Thanks to Doug for taking time out of his busy schedule to answer One Question for us. Check out previous installments of One Question content right here.