Long before Daijiro Yoshihara’s name became synonymous with Formula Drift, he was simply a 17-year-old kid, living a modest life in his native hometown of Tokyo, Japan. As a teenager, Yoshihara worked various jobs—at a trucking service and car dealership—to pay for schooling and support his passion for the sport called drifting, which was relatively unknown in the mainstream enthusiast community, but was quickly gaining steam.

“I was just a street drifter living in Hachioji, a city located in the western part of Tokyo, Japan. I frequented the Touge (mountain pass) in my AE86 Sprinter Trueno for fun. At the time, it was just a hobby. I never imagined that one day, drifting would define my career,” says Yoshihara.

“When I left Japan in 2013 to live out my stateside drifting career, I left behind one of my most prized possessions, my AE86.”

“By today’s standards, the AE86 is an ‘80s relic, but once you learn how you drive it and understand its characteristics, the vehicle will feel like it’s part of your body. The Hachiroku delivers a very raw and mechanical feel compared to today’s modern cars using the latest technology and driver assists. At the time, the AE86’s handling had no rival. It was on a level of its own. I believe that’s one of the reasons why it carries that stereotype as being such a great car, even by today’s standards. If I had a choice, without a doubt, I’d pick the AE86 over any car, including the 240SX,” he says.

“The idea of owning another AE86 did come to mind on numerous occasions, but due to a hectic schedule with the Formula Drift Championship Series and recent campaigns in the Lamborghini Super Trofeo series in Asia, things never panned out—until now. I’ve been given the opportunity to relive my youth with the AE86 R, thanks to Turn 14 Distribution and my supporting sponsors in building this dream machine. With this project build, we hope to draw plenty of attention as well as stir up some controversy inside the Turn 14 Distribution booth at this year’s SEMA and PRI show.”

According to Yoshihara, tracking down a Corolla GT-S in decent condition proved difficult. It just so happened his Formula Drift crew member, Chris Marion, was willing to part with one of his 15 rides. No sooner was cash exchanged between the two that the car was carted off to Evasive Motorsports for a complete teardown.

The crew at Evasive wasted no time in gutting the interior and pulling the 4AG engine, before loading the car back on the trailer to deliver it to Eimer Engineering in Anaheim. Chris Eimer is no stranger to building racecars under pressure, as a race fabricator that’s designed, welded, and built numerous cars, including Dai’s ’19 Formula D Subaru BRZ. Eimer has also played an integral part as Yoshihara’s Formula D crew chief for the past seven years.

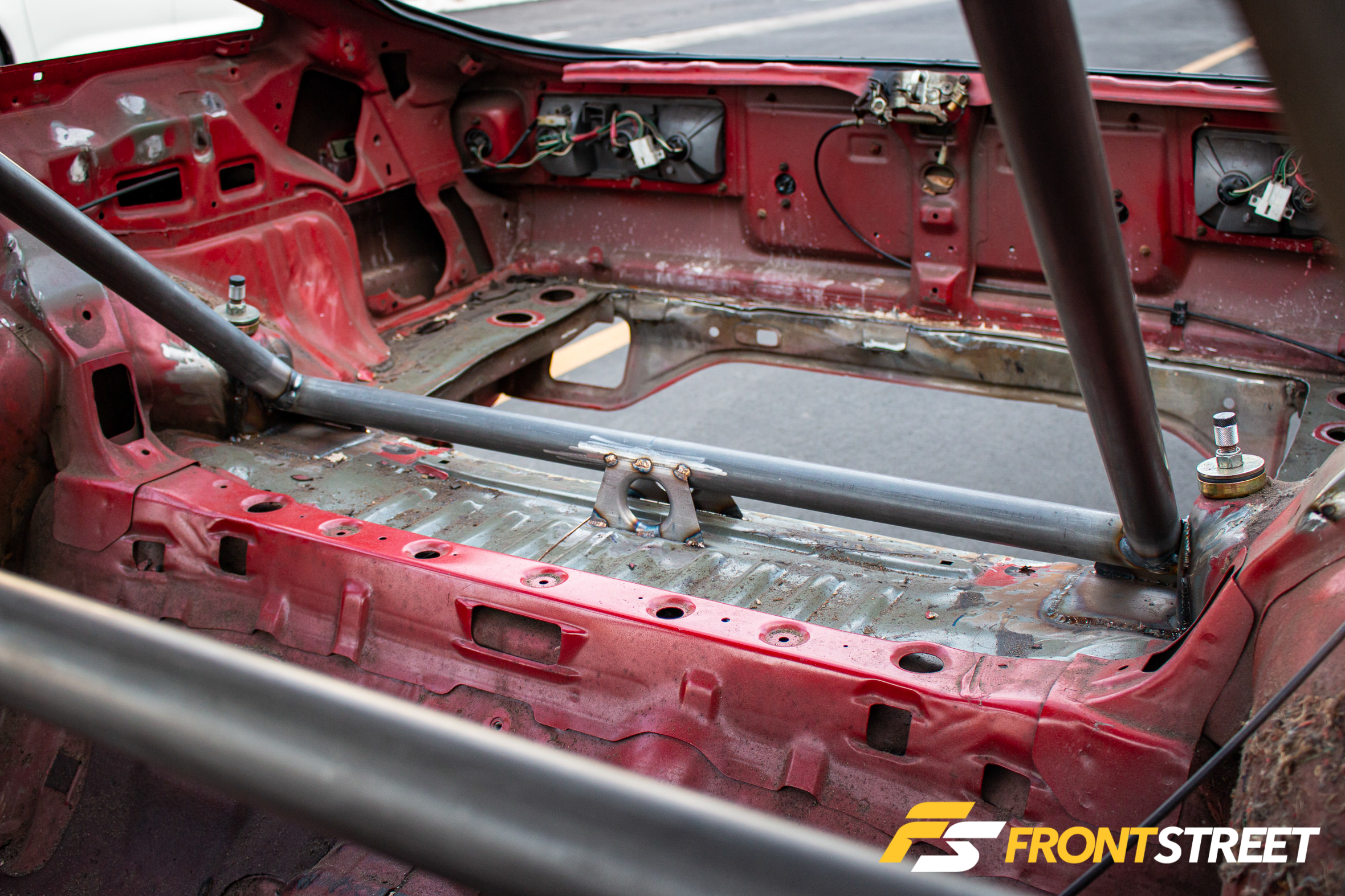

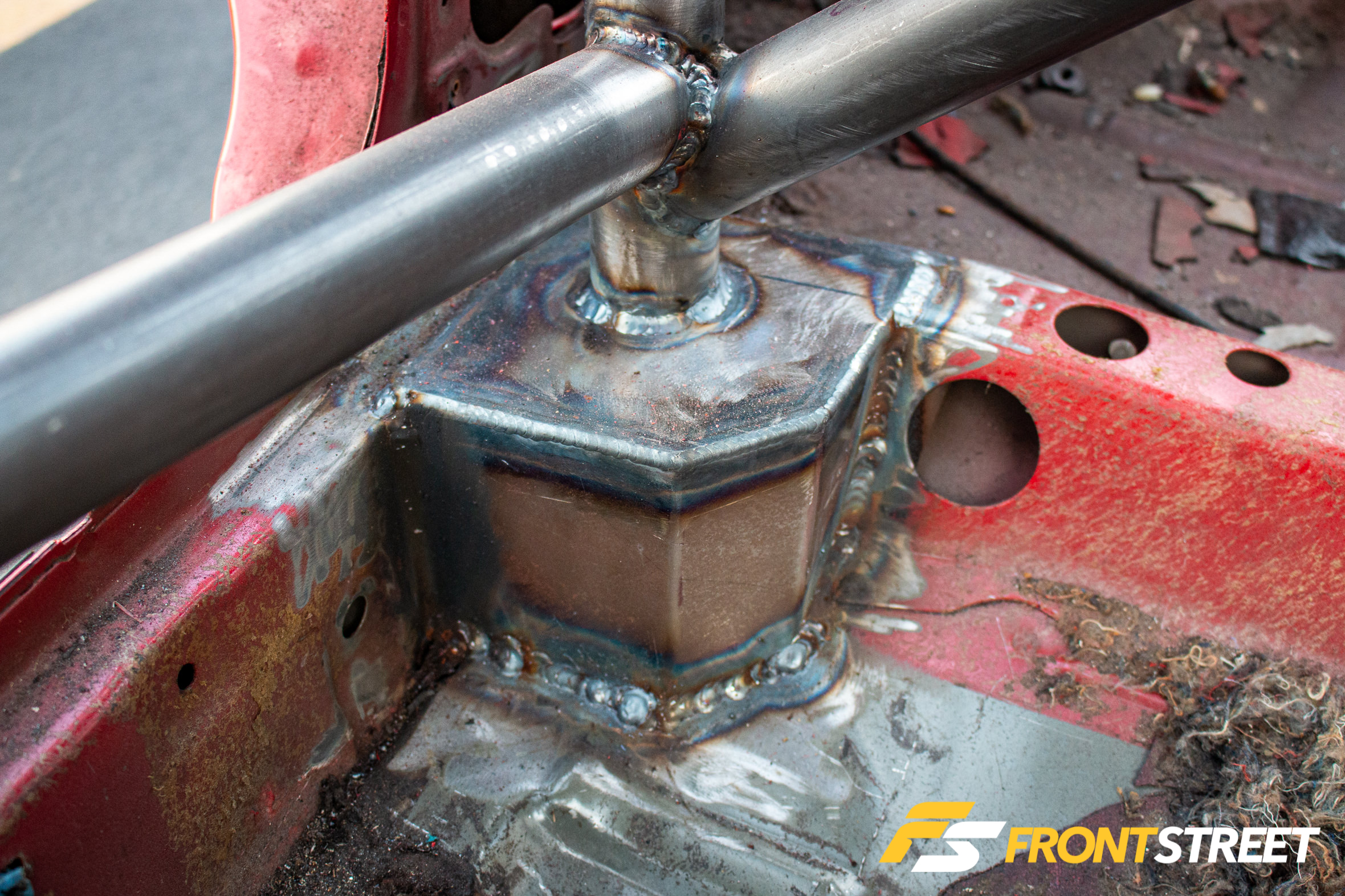

How fast does Eimer work, you ask? By the time I received word that the car was under construction at his shop, a custom chromoly roll cage was already fabricated and welded into place. Off-topic: an interesting fact about Eimer is that he cut his teeth as a builder and driver that heavily modified Hondas for drag and road racing.

The roll cage stiffens the chassis and provides more rigidity, so the AE86 R can perform better than the original 33-year-old unibody frame that flexes easily due to road undulations, engine torque, and hard cornering forces.

Before Dai’s purchase of the car, Marion had installed a MA46/MA47 Celica/Supra 7.5-inch rearend. The upgraded rearend swap comes in only 15mm wider than the original AE86 unit and serves as the perfect candidate to support the horsepower increase.

Speaking of horsepower, during our routine photo shoot visit at Eimer Engineering a few months back, we spotted Dai’s drift-spec BRZ being freshened-up following a third-place finish in round 5 of Formula D in Monroe, Washington.

Although Dai admits he isn’t the most skilled mechanic, we captured him offering Eimer his assistance.

Numerous access holes on the firewall were closed off to clean up the overall appearance.

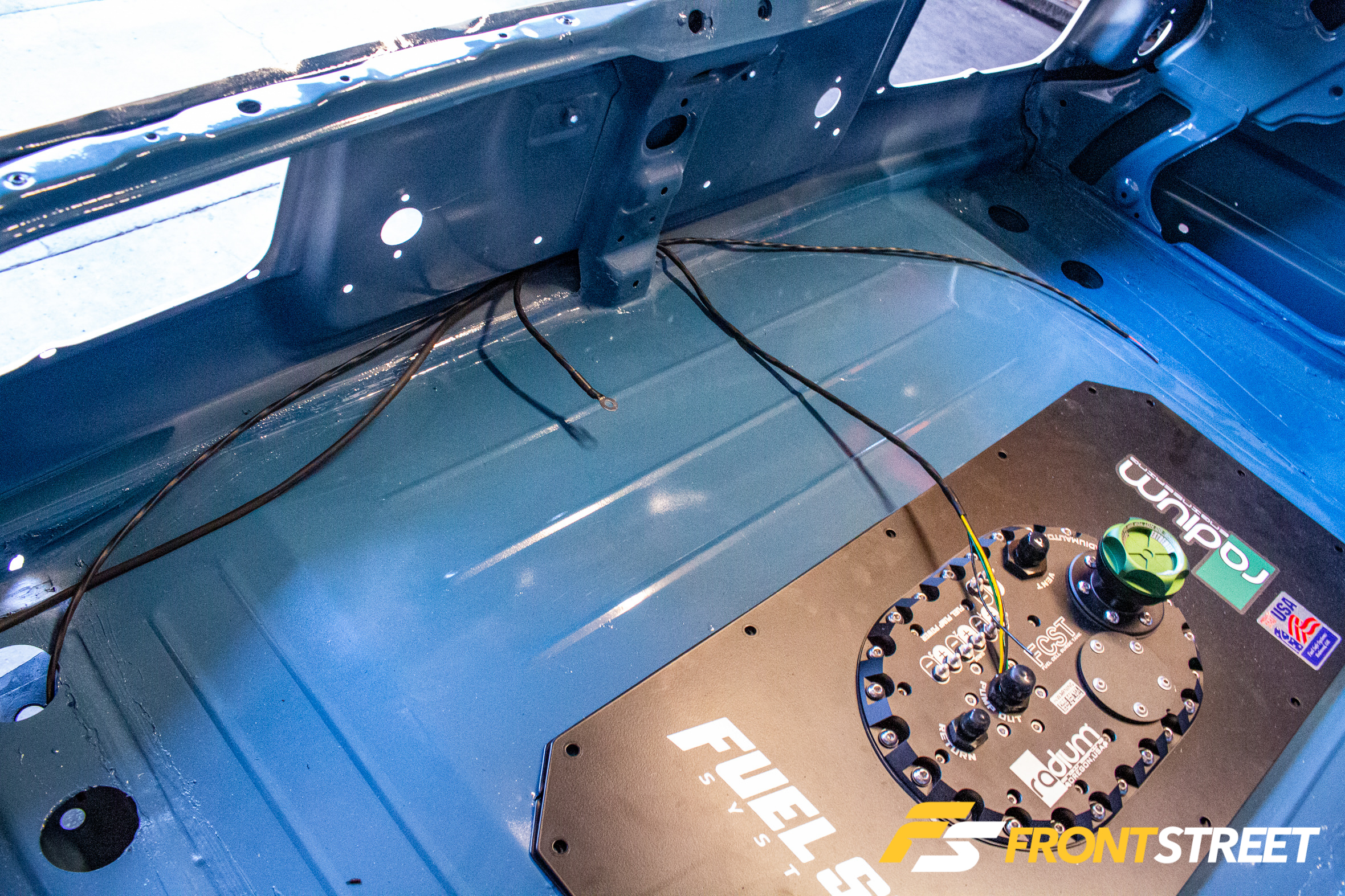

During the early stages of fabrication work, the spare tire well was cut out to make way for a Radium Engineering fuel cell surge tank.

Check out that look of joy on Dai’s face as he helped to weld in the fuel cell support brackets.

The Radium Engineering fuel cell surge tank features a dual-chamber setup to prevent fuel pump starvation issues. The design allows the use of a single or up to three surge tank pumps, all in a compact drop-in package.

Back in 2018, Yoshihara casually struck up a conversation with Kei Miura of TRA-Kyoto. Miura has built worldwide notoriety with his Rocket Bunny/Pandem Aero Kits.

“We have a great relationship, so I asked Miura-san if he was interested in designing a custom body kit for my AE86 R and was ecstatic that he agreed. It was a few months later that I learned his Pandem AE86 design was inspired by a vehicle he witnessed competing at the World Time Attack Championship in Sydney, Australia. Correct me if I am wrong, but to date, the only true widebody aero available for the AE86 was the TRD N2 kit,” says Yoshihara.

Following the completion of the kit, Miura was so pleased with the final design that he decided to offer the kit to the general public through his exclusive USA distributor, GReddy USA. The official release of the “Pandem 86” is scheduled to follow this year’s SEMA Show.

Ask any Corolla owner what the most difficult part of a restoration is, and we bet that the majority will mention purchasing OEM replacement parts—including fenders—in good condition, without getting price gouged. Rather than spending time scouring the internet, Yoshihara decided to pick up a set of aftermarket fiberglass fenders. Eimer proceeded to dry-fit the Pandem flares over the new replacement fender.

This close-up photo details the level of inner fender slicing and dicing needed for proper wheel clearance.

The rear widebody flares measured close to 120mm, an increase in overall body width by 9.6-inches. According to Yoshihara, the original design spec was slated as 70mm wide.

Every Rocket Bunny/Pandem aero kit begins with a full vehicle laser-scan. The vehicle scan creates a detailed 3D digital rendering of the stock profile and provides the ability to achieve precise fitment. The Pandem kit was spot-on and required minimal modifications.

Swapping over from a Trueno-style pop-up headlight configuration to the JDM Levin setup required replacing the hood. The carbon fiber hood was mocked up only to find out the hood safety latches were causing interference. Nothing that Eimer and a cutting saw couldn’t solve!

We were impressed with the uniform panel gaps, including the hood-to-fender alignment.

The entire body kit, including the side skirts, was mounted using Cleco fasteners. These temporary fasteners allow a quick install and removal process to test fit the kit before the final assembly.

The inner wheel wells were opened up to allow for full sweeping tire clearance. Yoshihara revealed that the car would be serving dual-purpose duties as both a drifting and road race machine.

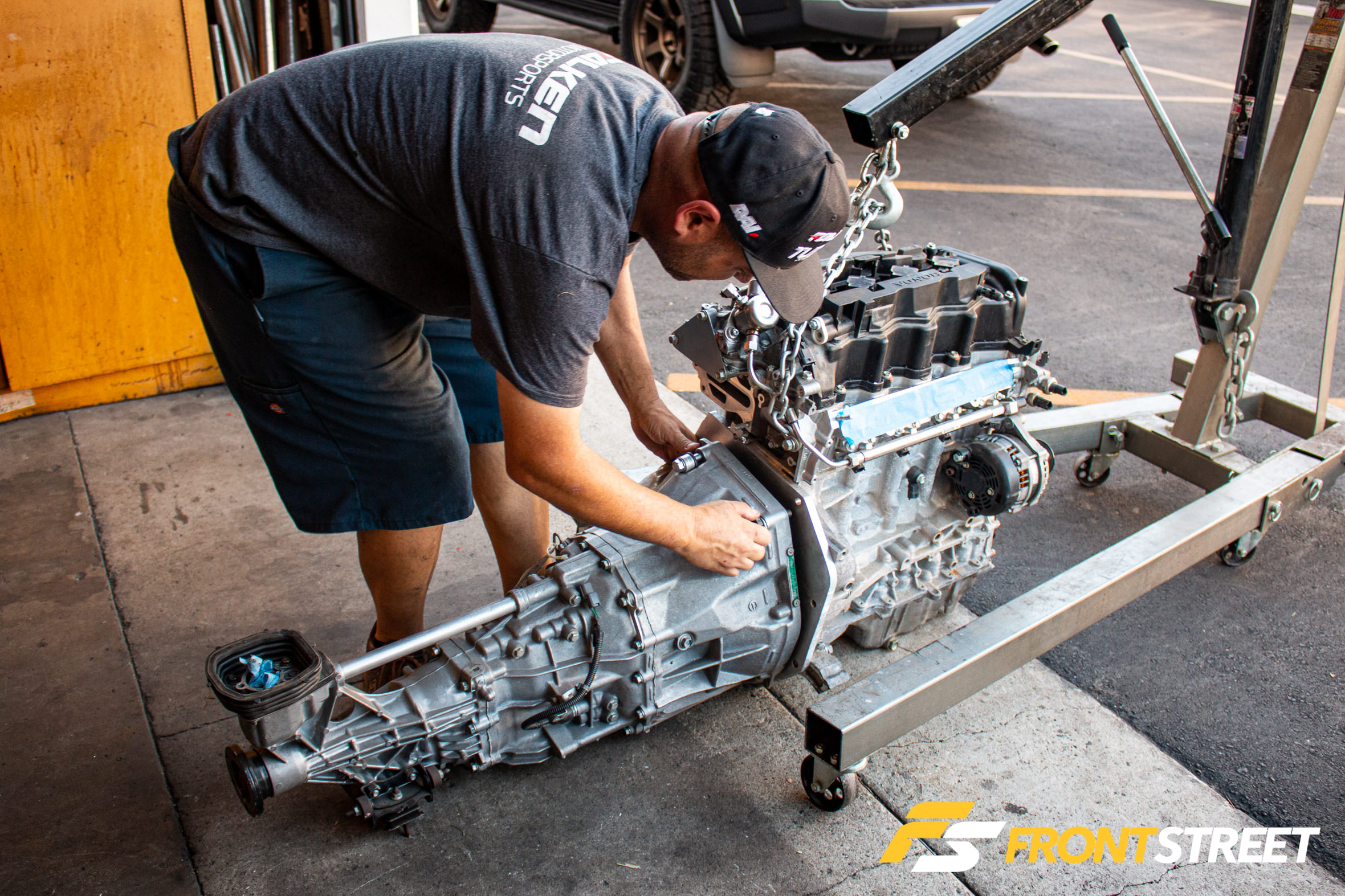

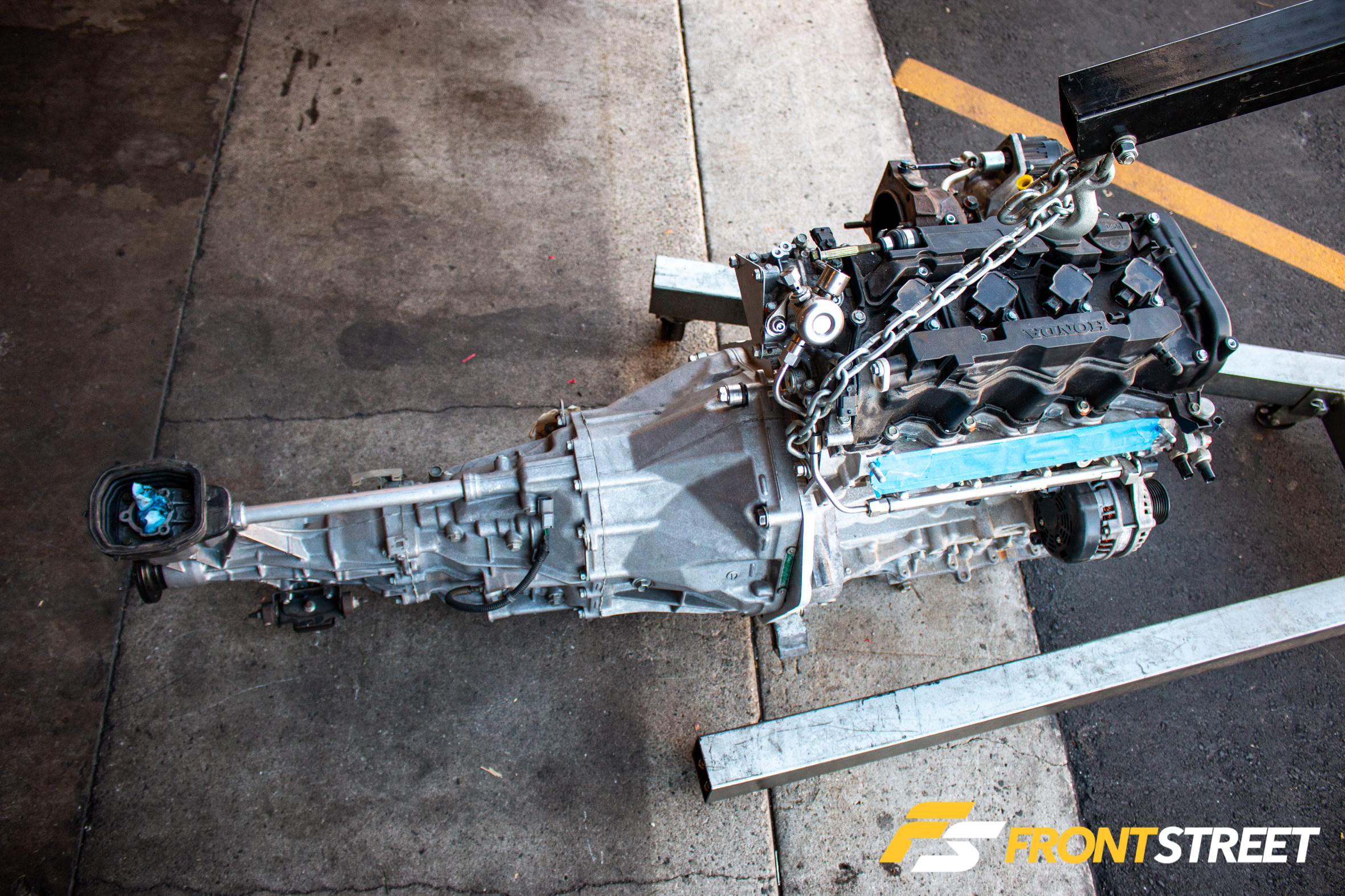

The Honda S2000 six-speed transmission is considerably larger than the original unit. Eimer displayed his arts and crafts skills by mocking up a new transmission cover in cardboard.

Numerous aluminum block-off plates were used to cover the original vent holes on both the trunk and doors.

While the body kit is currently a one-off piece, undoubtedly, the unique part of the build is what’s under the hood.

“The factory 4AG is a great engine but lacked the horsepower to make it a fun car to drive,” said Yoshihara.

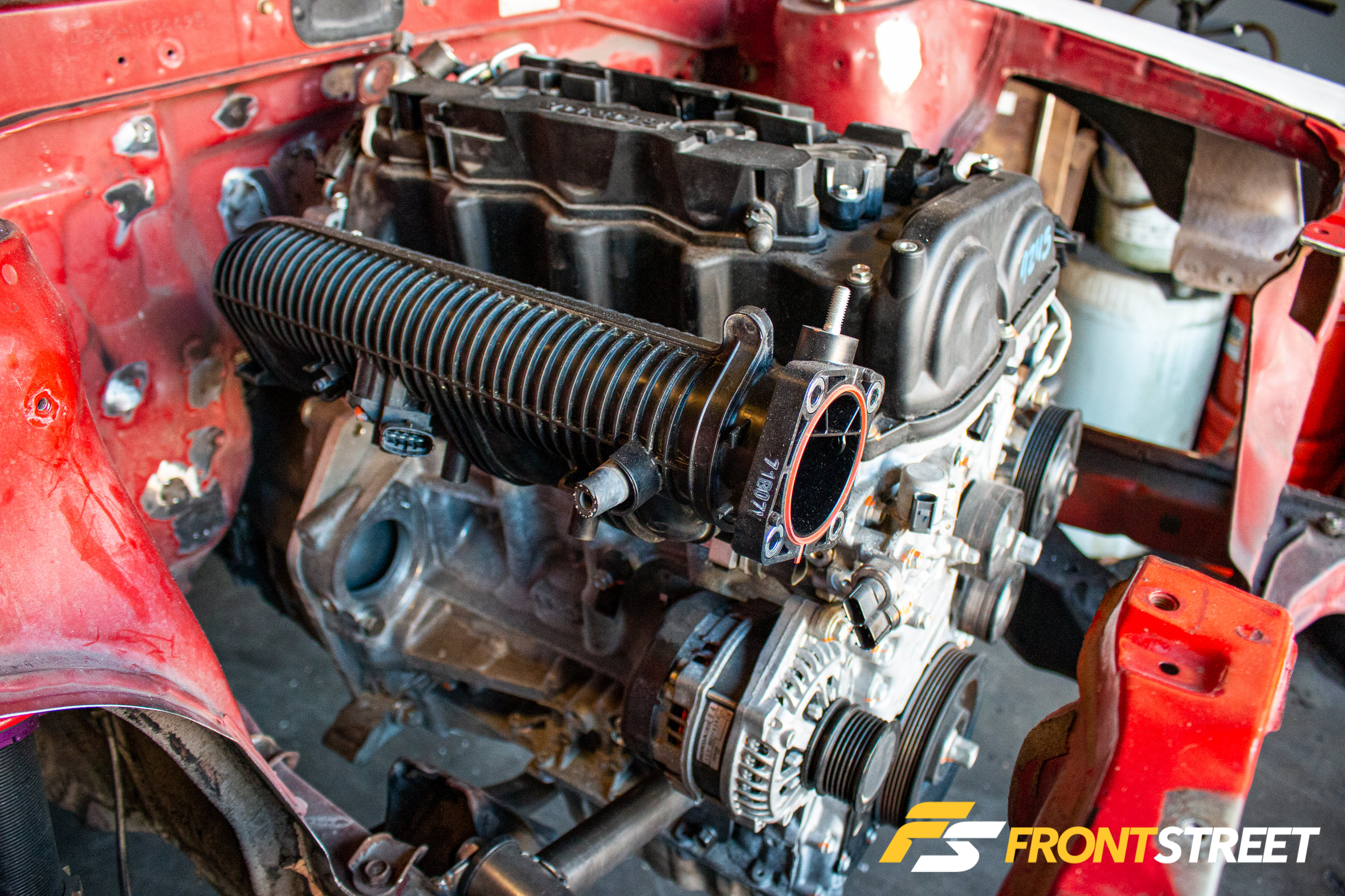

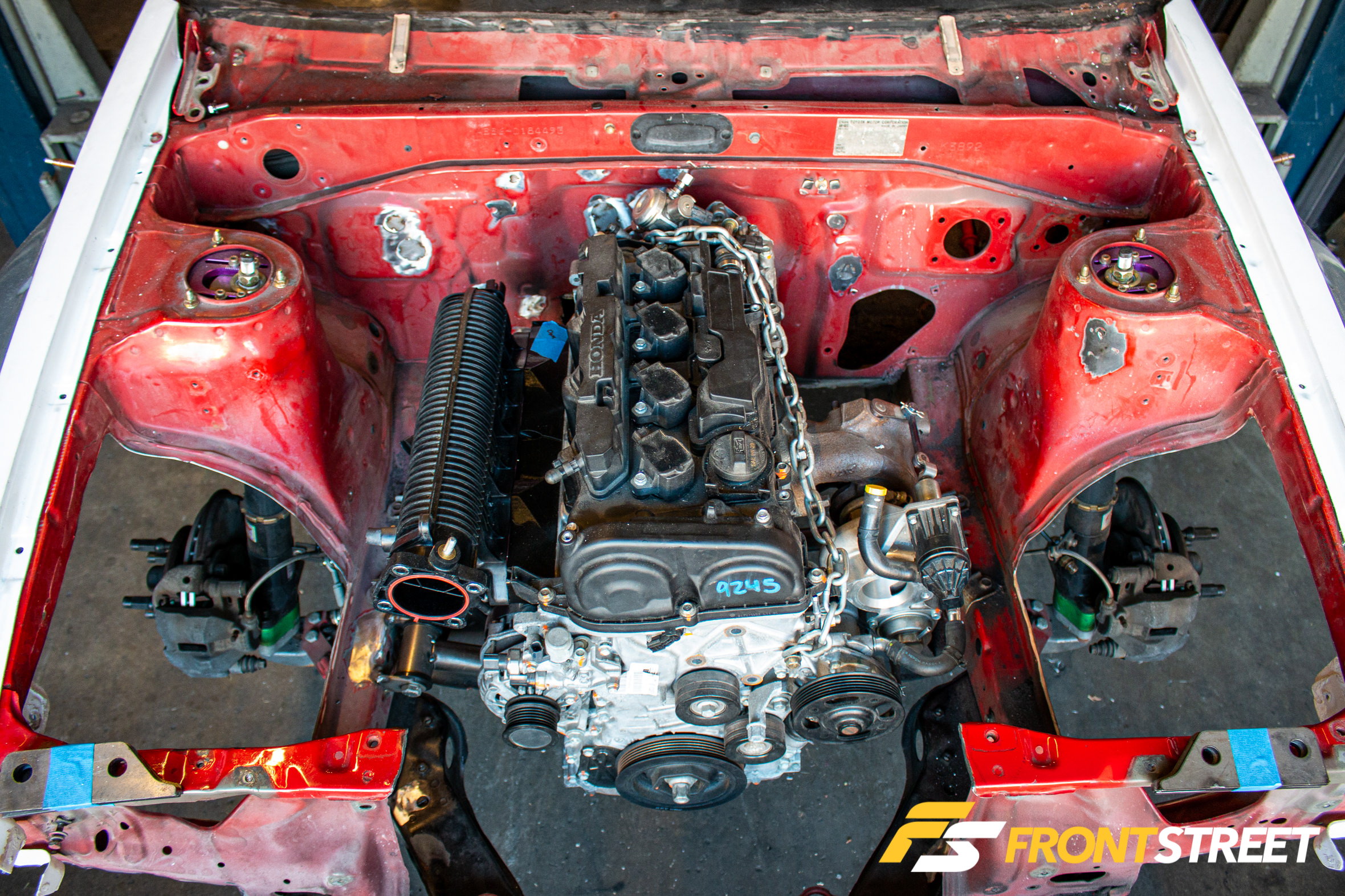

The factory crossmember was modified and re-welded with new engine mounts for the new powerplant to fit into the engine bay properly.

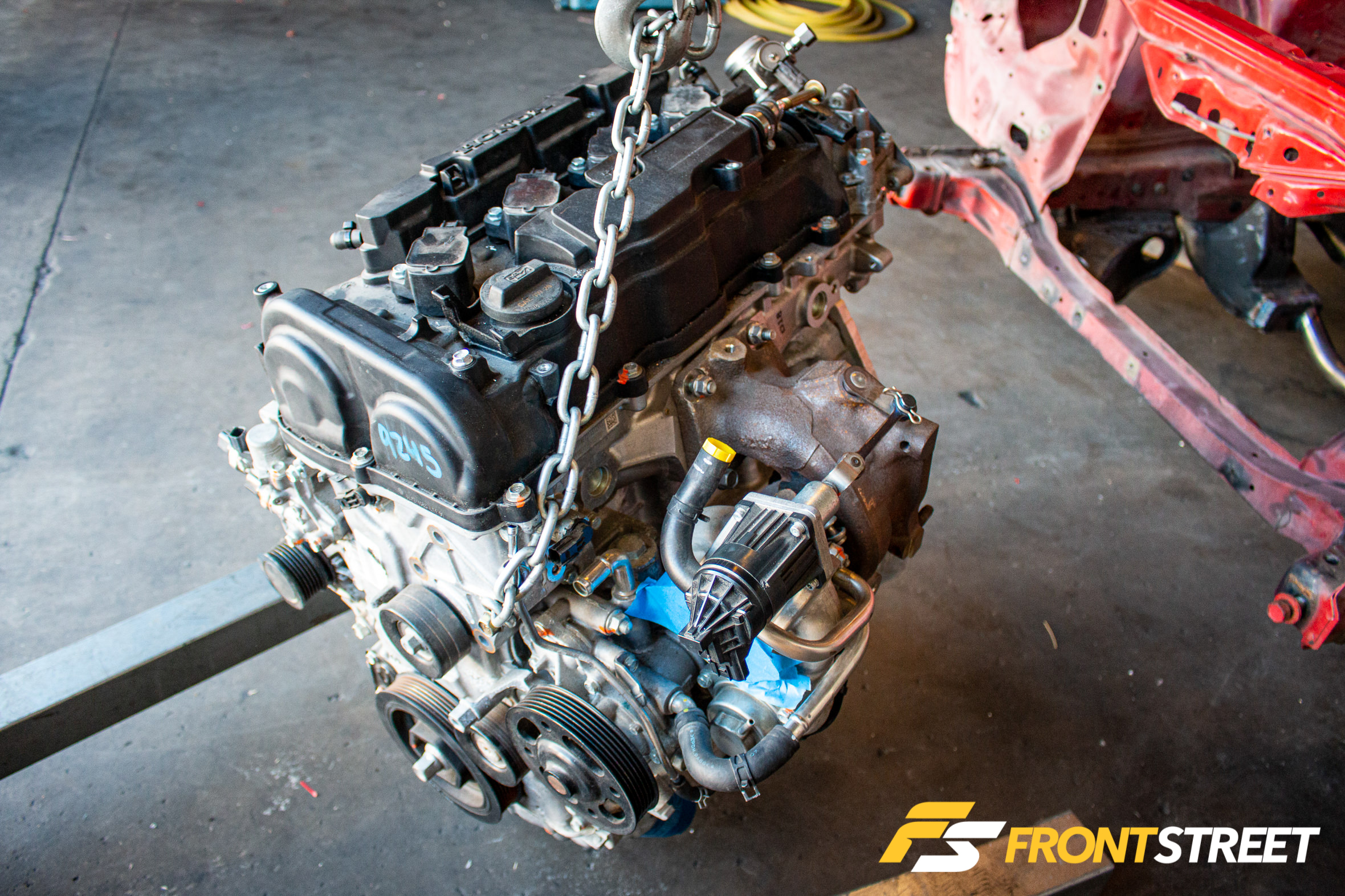

There are plenty of options when selecting a replacement powerplant, including the K20, K24, SR20, and even the option of an LS V8-powered engine, but according to Yoshihara, his decisions boiled down to his specific requirements. The breakdown consisted of retaining a 4-cylinder platform with a strong powerband, the potential to make horsepower, and, most importantly, reliability. When all’s said and done, he decided to pick the ’15-current FK8 Civic Type R powerplant. The K20C1 is a direct-injected, turbocharged, 2.0-liter engine that produces 306 horsepower and 295 lb-ft of torque from the factory, and is also found powering race cars in the Formula 3 and 4 series.

“We wanted to stand out from the crowd and create something different from your typical Corolla,” said Yoshihara.

“This build is unique, and we are the first to use the K20C1 in an AE86 Corolla. The Honda K20C1 crate engine delivers good horsepower straight from the factory, which means we don’t have to radically modify it other than providing a good fuel management tune, a free-flowing exhaust, and adding some minor upgrades.”

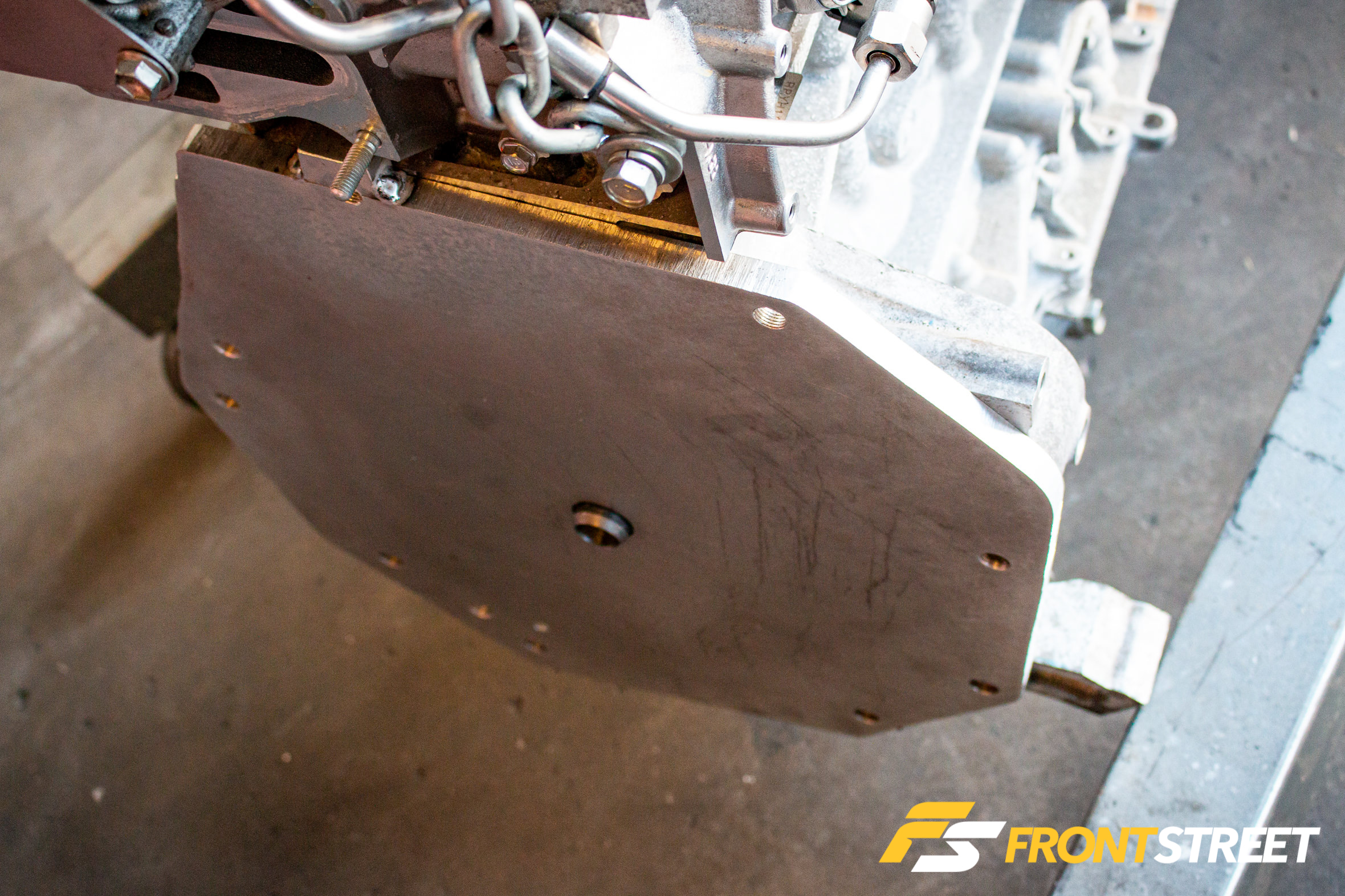

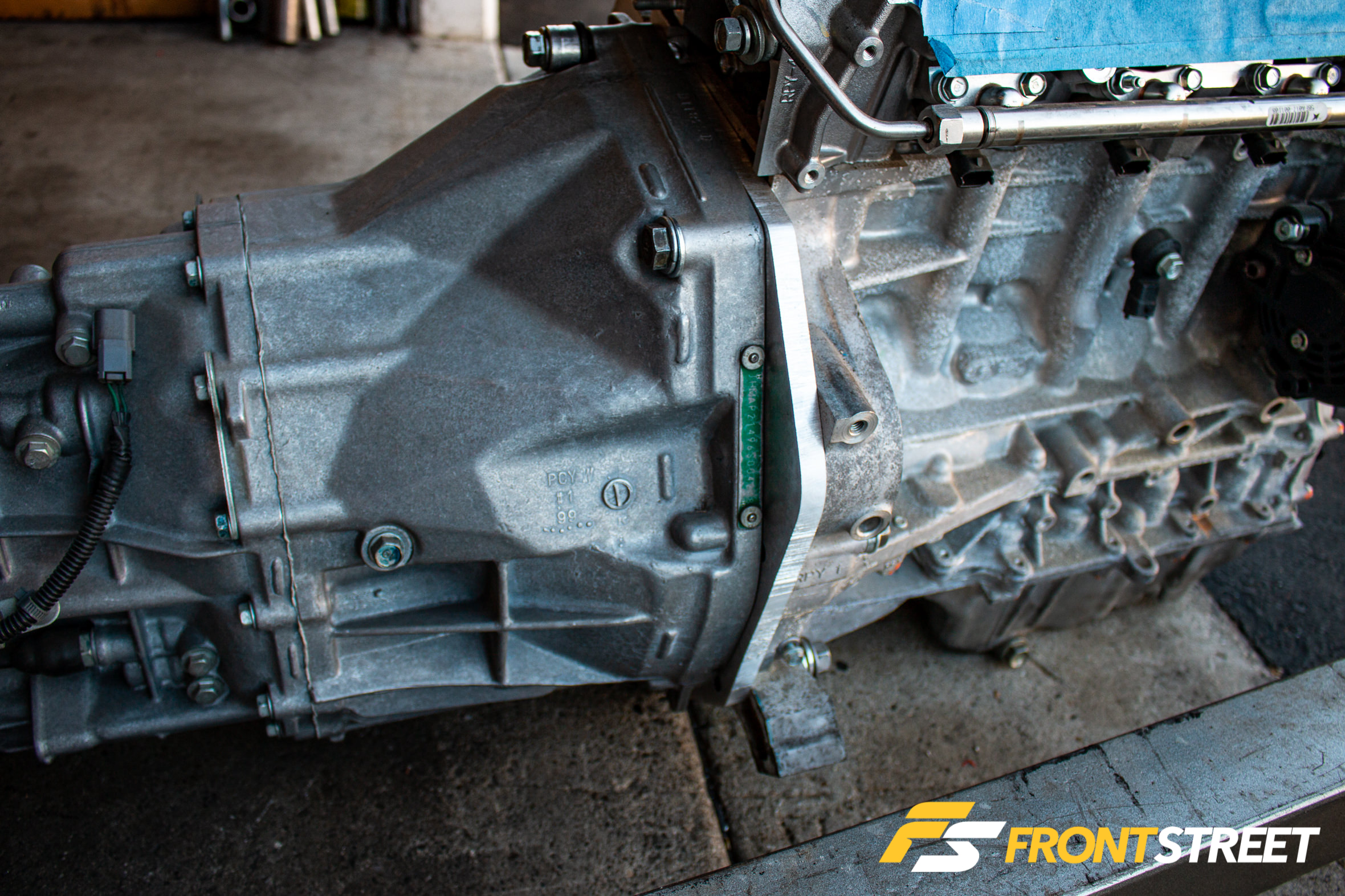

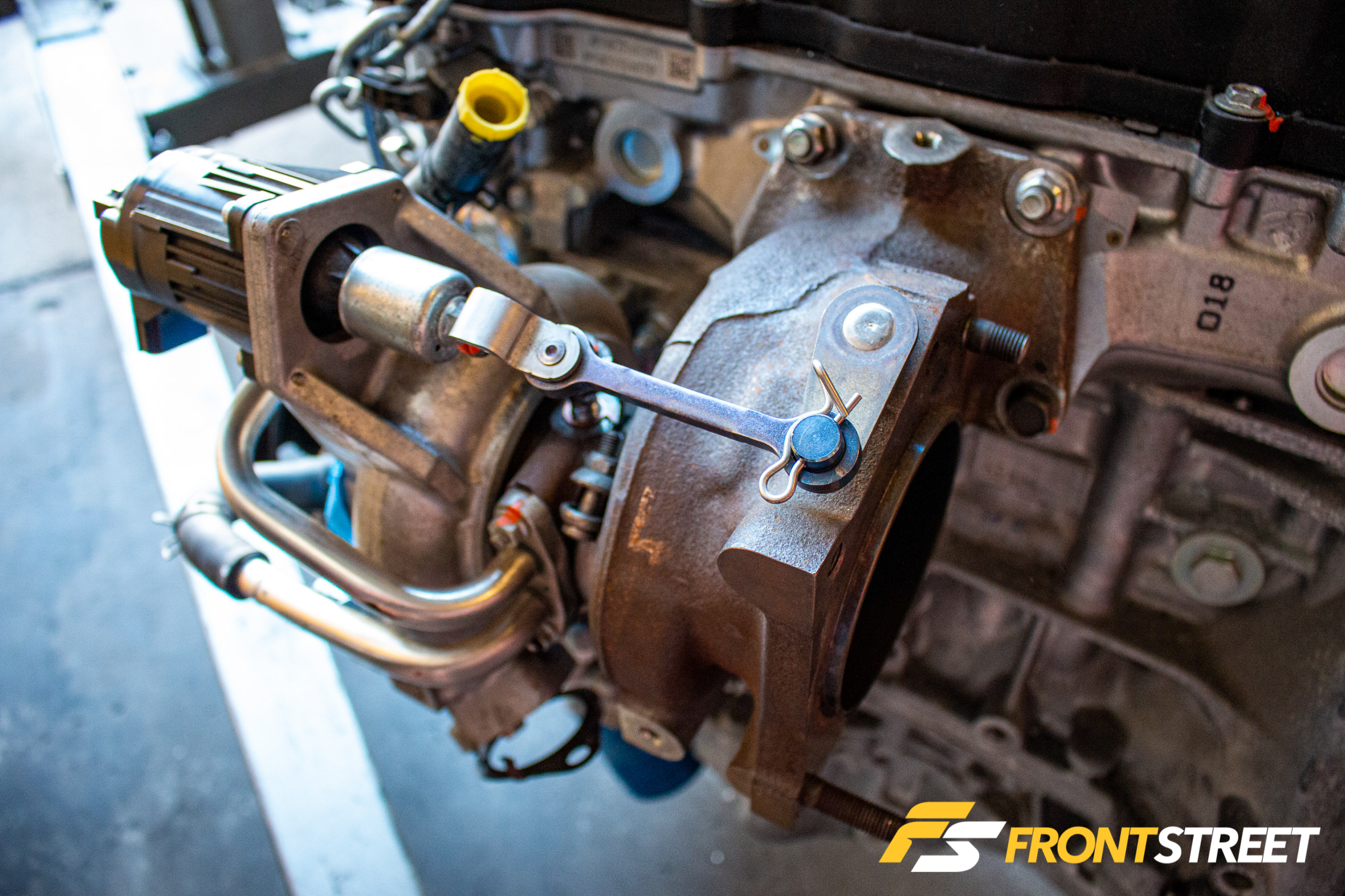

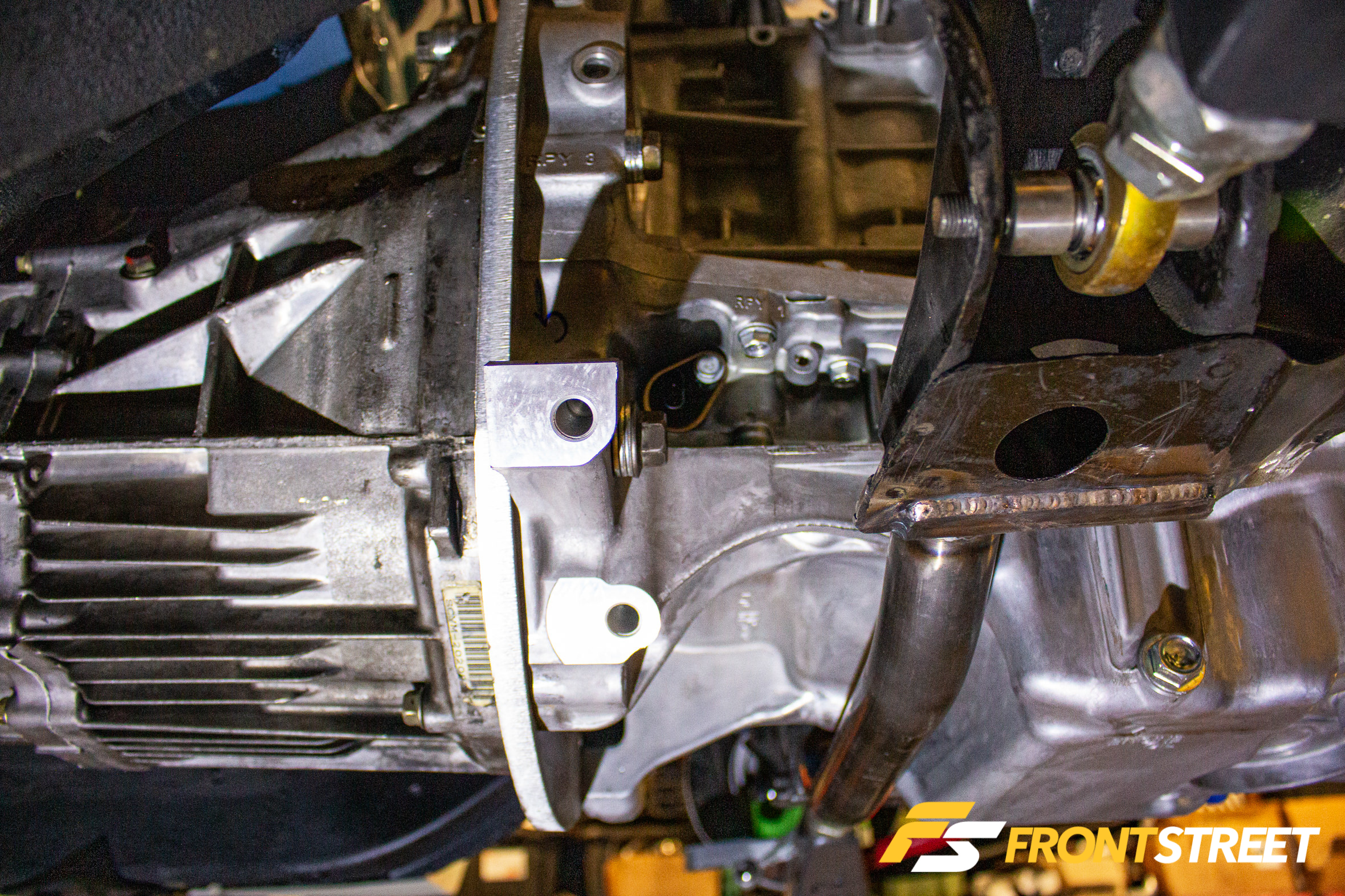

Eimer Engineering fabricated a custom bellhousing adapter plate to mate the Honda S2000 transmission with the K20C1 engine.

Honda fanatics might be asking the following question: “Why not use a K20 or K24 engine rather than a K20C1 engine?” and Dai provided us with the answer.

“We wanted to build a unique car that was able to deliver a reliable range of 350 to 400 horsepower. The beauty of this engine is the reliability factor,” said Yoshihara.

Companies like 4P Racing (4 Piston Cylinder Heads) have already begun dissecting and testing the K20C1 cylinder head to unlock its horsepower potential. 4P has noted that the K20C1 cylinder head can improve flow capacity from the factory 150 cfm capability to 300cfm by massaging the factory ports. The flow rates are noted as the same as the K20. The potential is there.

A McLeod Racing clutch assembly, flywheel, and other powertrain components were all sourced using Honda S2000 parts.

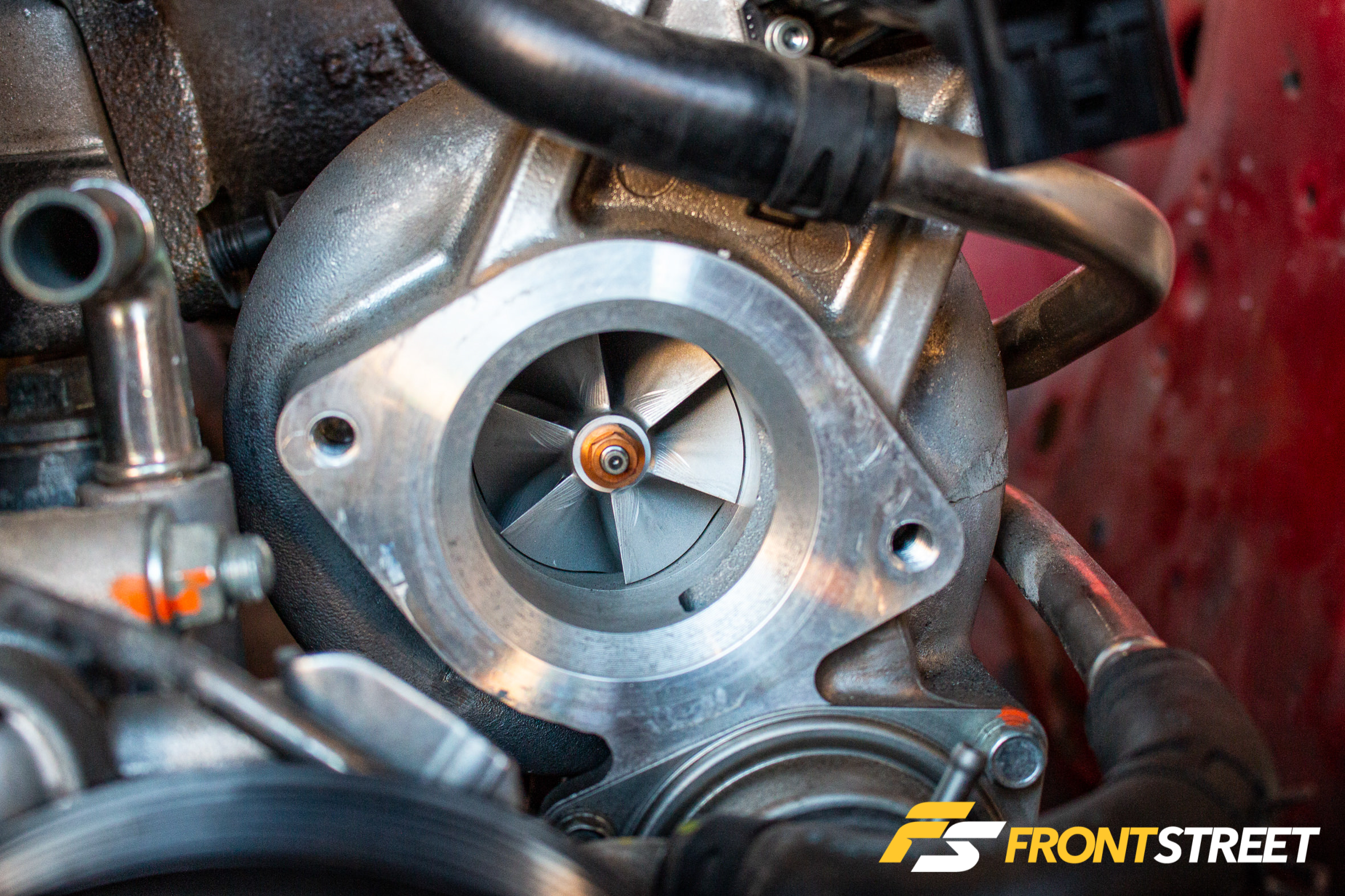

The difference between the K20C1 engine and Honda engines of the past is the direct injection and tumble-port design. The power response is nearly instantaneous as the boost comes in at 2,500 rpm.

A quick test-fitment was performed to fabricate the engine and transmission mounts before sending it off for paint.

The factory Mitsubishi single-scroll TD04 turbocharger with an electric wastegate offered plenty of clearance between the strut tower and sidewalls. Notice that the engine exhaust manifold integrates within the head—a solution that saves weight and heightens turbo response.

The engine is positioned as close as possible to the firewall and sits at the lowest point to provide ideal weight distribution and vehicle balance.

“We didn’t want to mount the engine too low as it would cause issues with ground clearance. We decided to offer sufficient clearance to clear obstacles such as track berms if and when he decides to stretch its legs for some road racing,” mentioned Eimer.

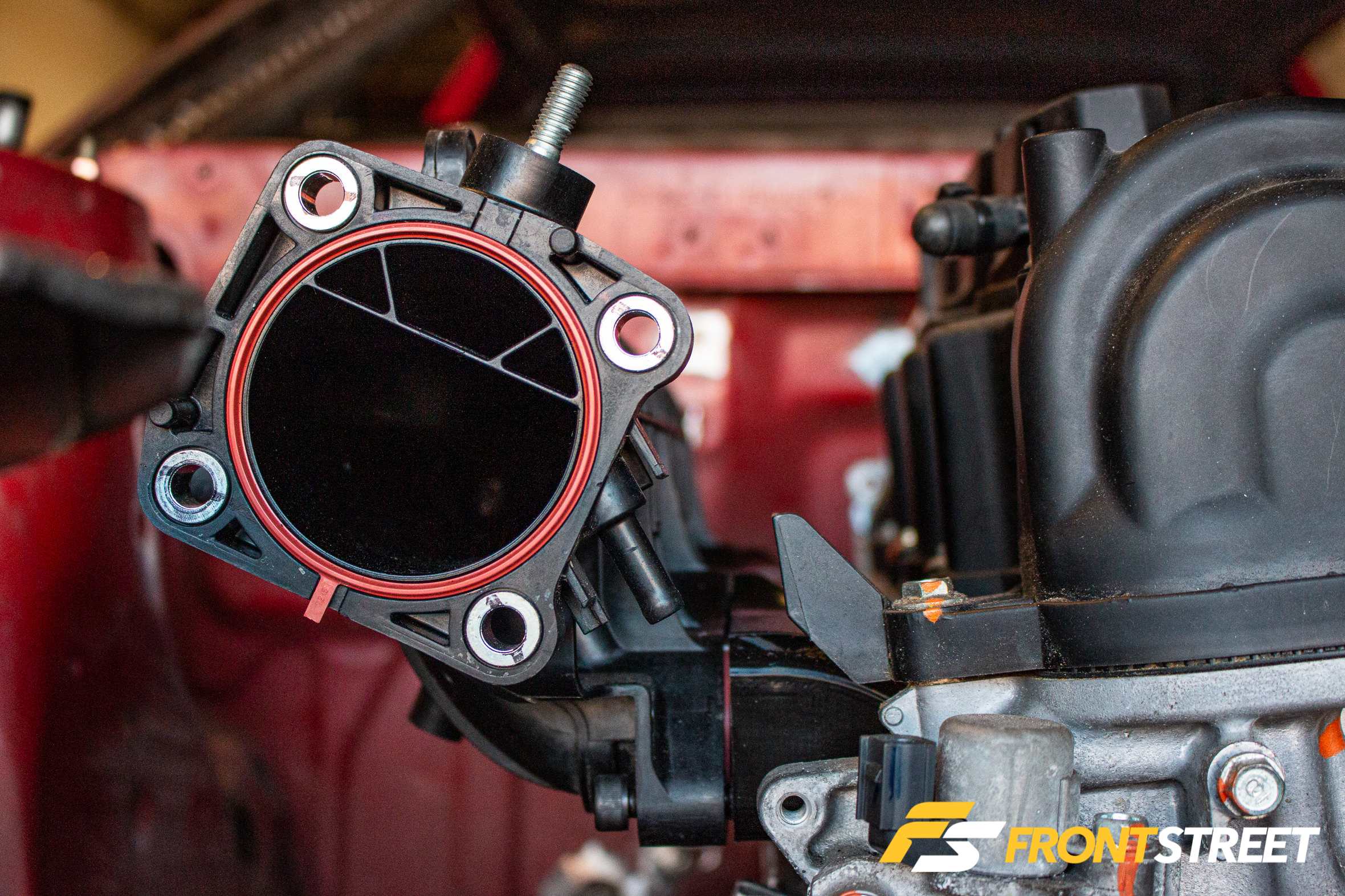

Honda enthusiasts will immediately recognize the unique modifications made to the intake manifold. A custom Eimer 3D-printed adapter allowed the composite manifold to be flipped 180-degrees, which permits the inlet location to be in the ideal position for the soon-to-be installed inlet charge pipe setup.

If the engine cover didn’t say Honda on top, you would think this clean engine setup was factory-installed.

Following the final test fitment, the vehicle was sent to Elite One in Fontana to freshen up the body and repair the rusty speed holes. The entire shell then covered in Championship White pigment.

The AE86 R’s interior received a contrasting coat of Cavalry Blue, a color found exclusively on Toyota’s TRD Pro vehicle lineup.

The fuel cell was reinstalled and finished up with a custom wire harness assembled by Eimer.

The final view of the completed transmission cover which houses the custom shifter and hydraulic e-brake assembly.

Eimer used a seam sealer on all four fenders before installing the Pandem widebody kit. We asked if he used any special sealer and were surprised to find out that the DAP polymer sealant sold at your local Home Depot is more than sufficient to ensure a watertight bond.

With SEMA less than three weeks away at the time of this shoot, the team kicked things into high gear as they juggled building the car while preparing for the final round of Formula D at Irwindale Raceway (stay tuned for coverage of that next week).

Next, I walked into the shop the following Tuesday—two days after Formula D—and immediately saw some serious progress had been made. The iconic Sprinter taillights, body kit, and bumpers were all in place.

A quick peek under the rear bumper revealed a drift-inspired bash bar.

The Sparco QRT-R limited-edition bucket seats were mocked up and ready to be positioned to Dai’s specifications.

Here’s a close-up of the AE86 R’s custom transmission mount and bellhousing adapter plate.

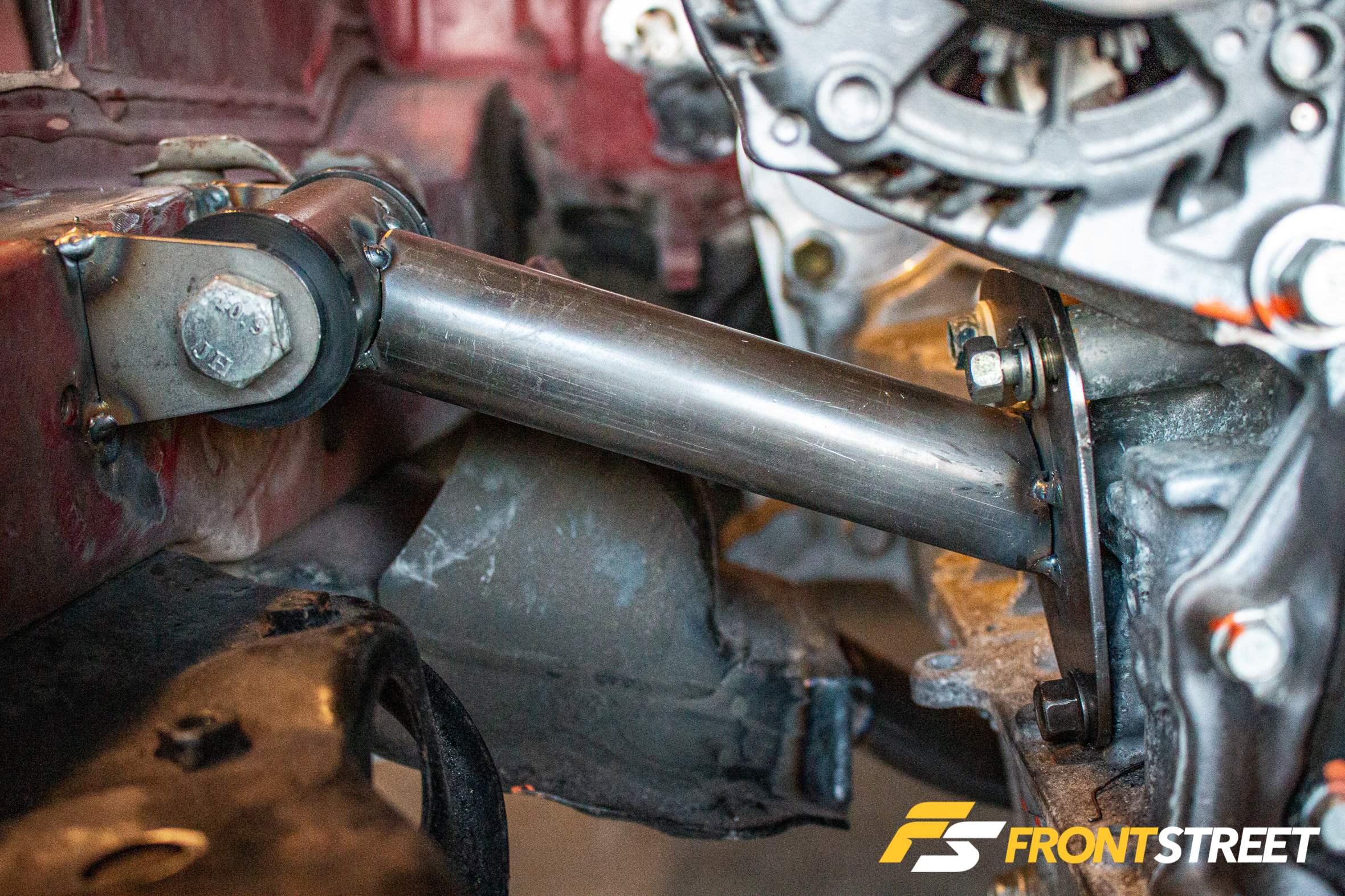

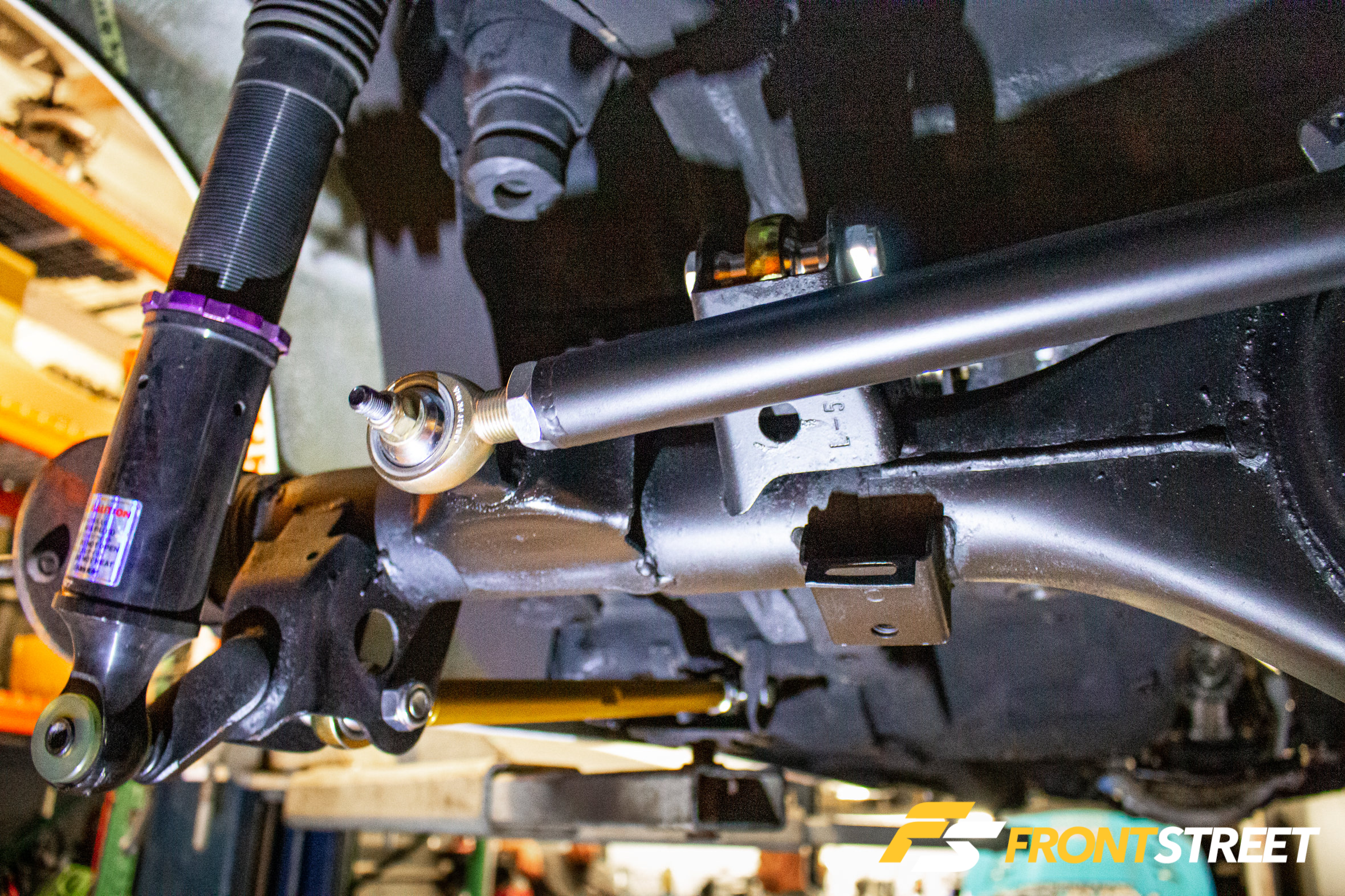

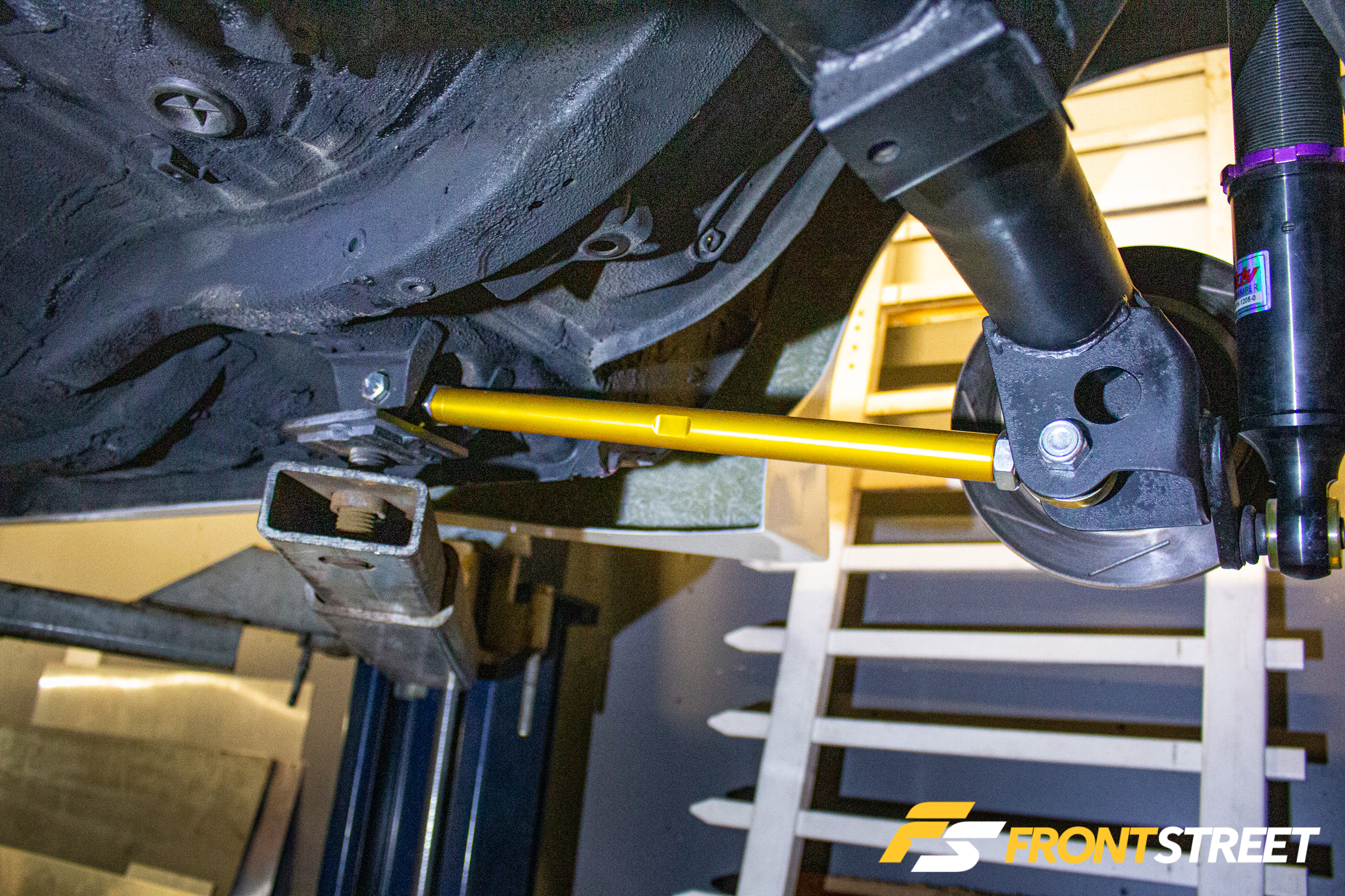

A custom lateral bar and Techno Toy Tuning custom 4-link rear trailing arms with spherical rod ends were installed to provide improved handling with zero deflection.

At the time of our shoot, the wheels were still in transit, but Yoshihara mentioned that a custom set of BBS wheels in 15×9 with -30 offset upfront and 15×9 -75 offset towards the rear, wrapped in 245/45-15-inch Azenis RT660 tires, will fill the gratuitous fender arches. Also in transit were the custom KW Suspensions 3-way coilovers that will be handling the footwork.

The K20C1 utilizes Honda’s VTC (Variable Valve Timing Control) for both intake and exhaust. Also, Variable Valve Timing (VVT) and Lift Electronic Control (i-VTEC) orchestrates valve lift, timing, and duration of the exhaust valve opening to reduce turbo lag through increased exhaust pressure at lower rpm. A Spoon Sports valve cover gives the engine bay a splash of color.

The brake and clutch master cylinder assembly were re-plumbed using stainless steel hard lines, as a means to replace the worn-out factory parts and help improve the engine bay’s visual appearance.

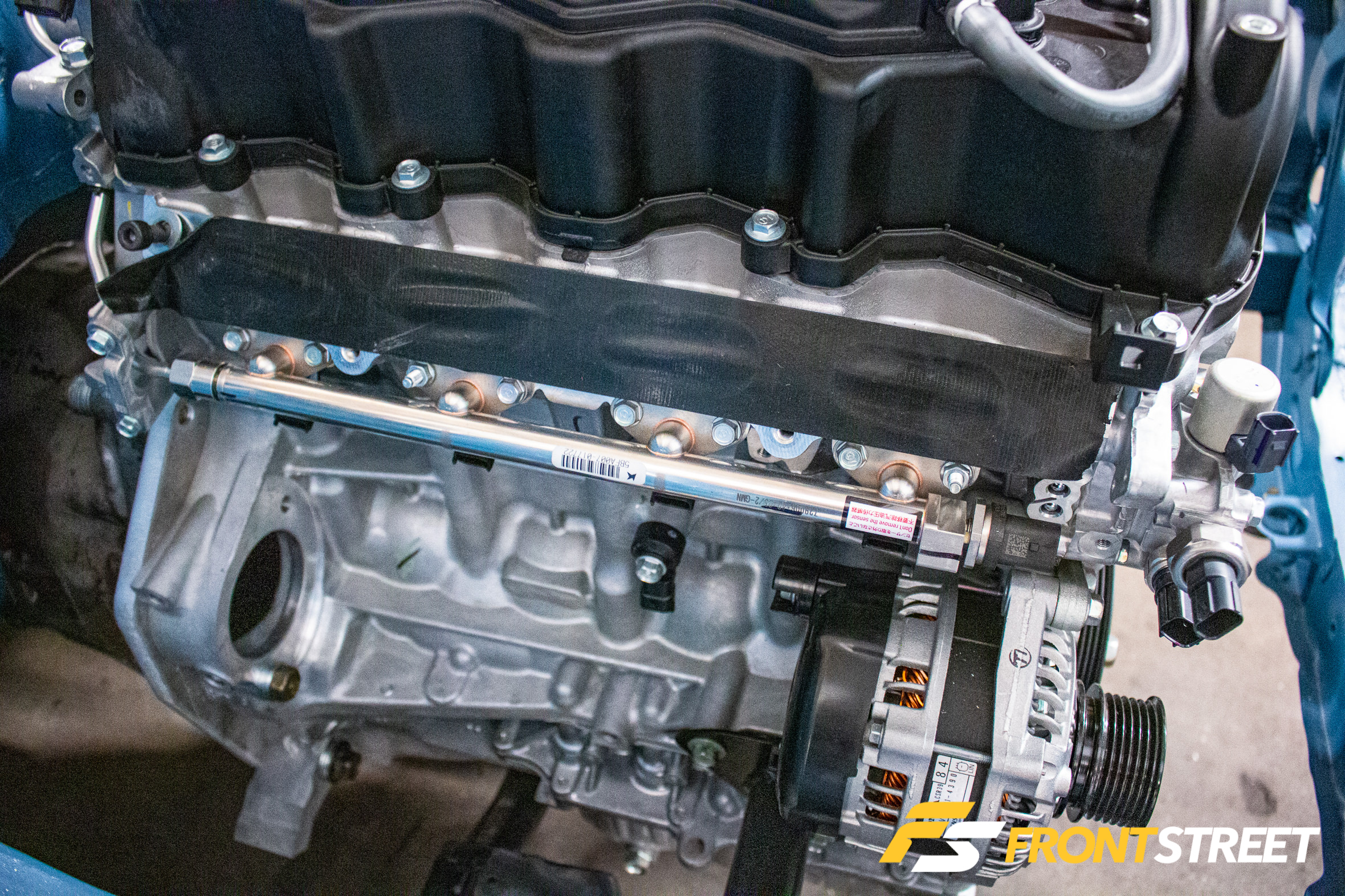

The K20C1 engine runs a direct-injection system with multi-hole direct fuel injectors. The shapes of the intake ports we previously mentioned were designed to generate a strong tumble flow to promote maximum fuel mixture efficiency. Notice how close the high-pressure regulator sits from the firewall.

We’re a bit disappointed we couldn’t show you the finished e-brake setup, but this system will be similar to what Dai uses in his professional drift car.

Vision Autoworks designed a one-off headlight using the factory housings. A set of Honda Accord Euro R projectors were retrofitted inside to create a custom look and provide a uniform beam of light.

CSF Radiators stepped up to the plate and delivered their universal tuck radiator. This dual-pass radiator was modified with mounting brackets before it was sent off for polishing.

A peek under the completed front fender puts into perspective how wide the Pandem kit is when compared to the original.

At the time of this shoot, the team is currently debating on using Lexan on both the rear quarter and hatch.

A set of 5-point Sparco harnesses provide driver support as well as comfort both on-and-off the track.

A Speedway Motors collapsible steering column with quick release provided a cleaner alternative in comparison to the factory piece that retains turn signals and electronics.

The cluster was also replaced using a Link MXS Strada dash display, powered by Aim Technologies, and the custom dry carbon fiber dash also contributed weight savings.

“The unique part of the build was the Honda engine. There’s a reason why you don’t see other people using the K20C1 is primarily due to its direct-injection setup. To make the swap run efficiently, you’d have to run a standalone ECU that currently, only one company offers. Not to mention at a rather high price. It’s been said that no other ECU company was able to crack the code, but Link Engine Management figured it out for a competitive price point. They’ve been able to support us from the initial build with their G4+ Force GDI direct injection ECU. I think their ECU is potentially a big market for FK8 Civic owner and the Honda community in general,” said Yoshihara.

With less than a week till SEMA, the team continues to push forward to complete Dai’s AE86 R dream machine. Due to time constraints, we weren’t able to show you every aspect of the build, but be sure to visit the all-new Turn 14 Distribution SEMA booth (#21321) to see the final completed version.

[table id=13 /]