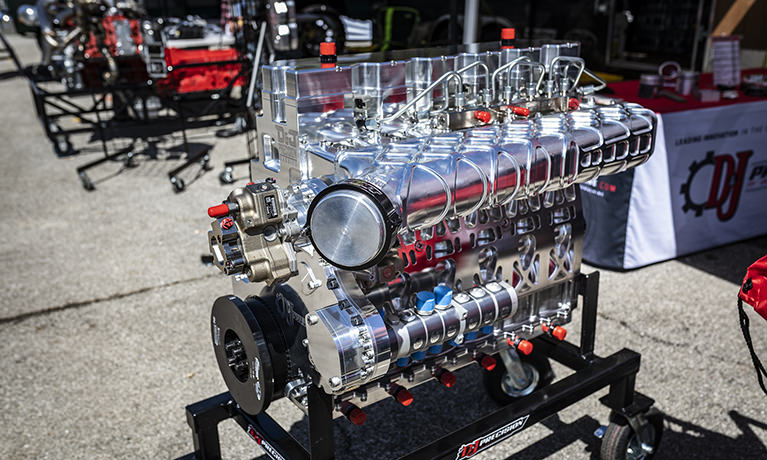

Diesel-powered trucks and the pursuit of diesel performance remains one of the hottest topics in the performance world today. Diesel enthusiasts are pushing every button in their quest to wring more and more power out of the world’s premier internal combustion engines, and leading the charge to advance performance from Cummins diesel engines is D&J Precision Machine in Cambridge, Ohio. D&J specializes in Cummins engines, supporting enthusiasts with complete crate engines, cylinder heads, custom rods and pistons, and all of the accessories necessary to breathe real fire into this stout platform. Over the last several years, they have worked hand-in-hand with the Cummins fanatics at Firepunk Diesel. This all-new, freshly designed engine—dubbed the Executioner—is headed to its new home between the frame rails of the Firepunk team’s Save The Racks S-10 previously featured right here on Front Street.

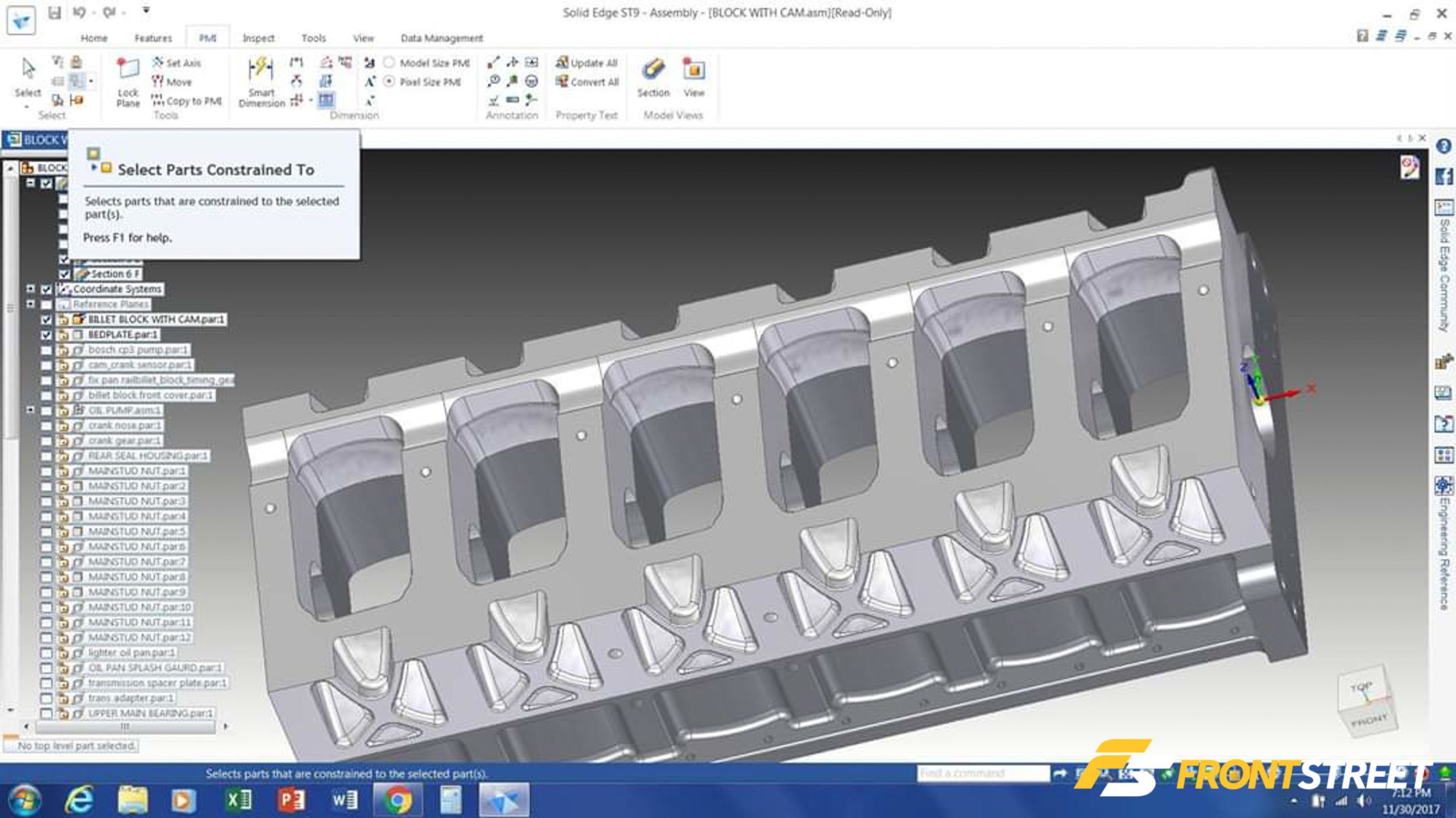

The Executioner’s design team consisted of Drew Pumphrey, Tim McQuain, and AJ Compton. Among the problems they identified in factory Cummins engines are multiple main web failures in the OEM cylinder block. These occur when enthusiasts push them well beyond the limits of the original design, particularly in drag racing applications. D&J found that after numerous attempts, they could not sufficiently improve the factory block to meet the growing challenges of racing applications, especially with racers like Firepunk Diesel’s Lavon and Lyn Miller pushing the limits of what is possible with the engine configuration.

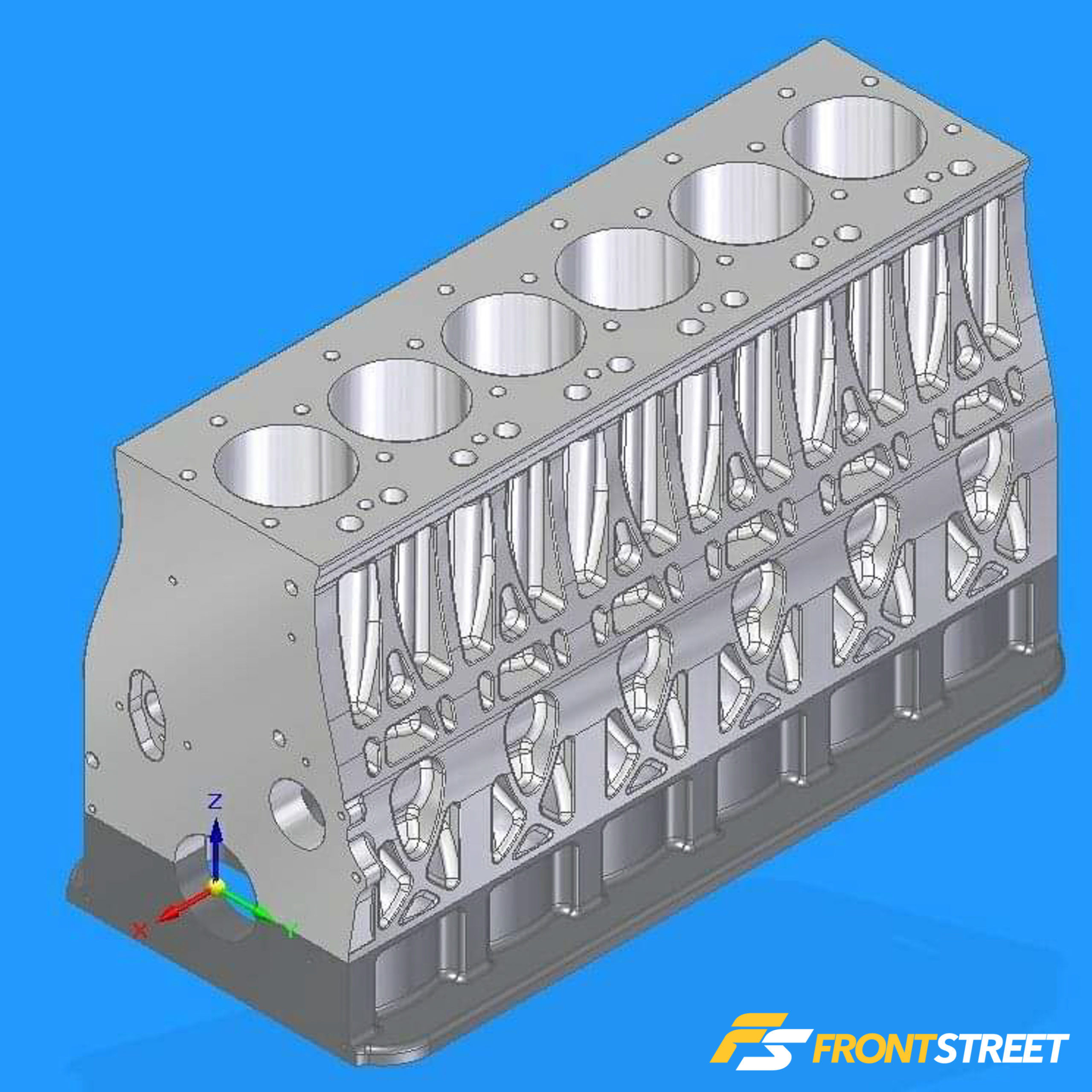

Accordingly, they decided to start from scratch by designing a cylinder block to eliminate the problems. Most racing rule books specify that a factory crankshaft must fit in the cylinder block, so the new block is purposely designed around that requirement. And, of course, it will accept any custom-machined billet aftermarket crankshaft as well.

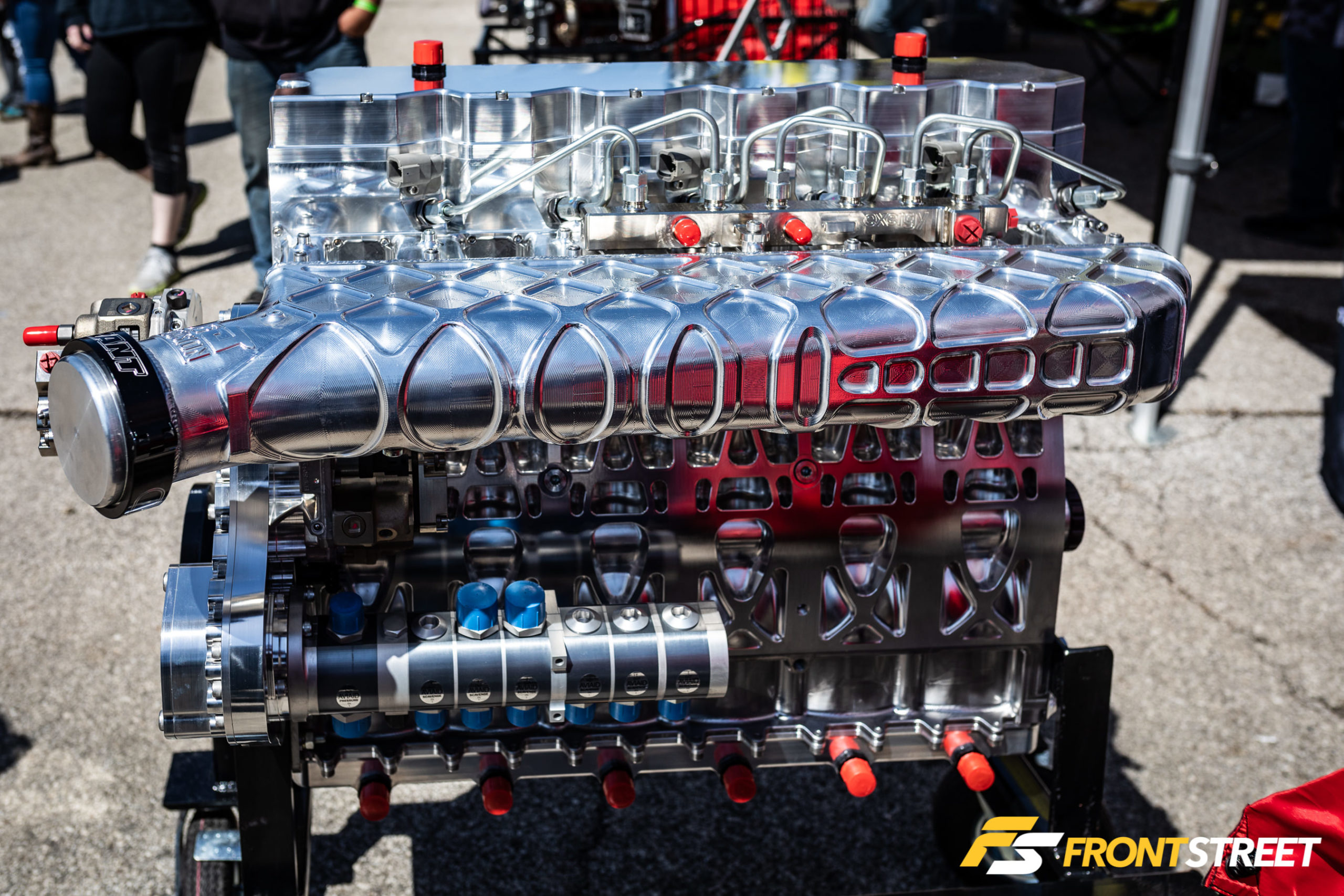

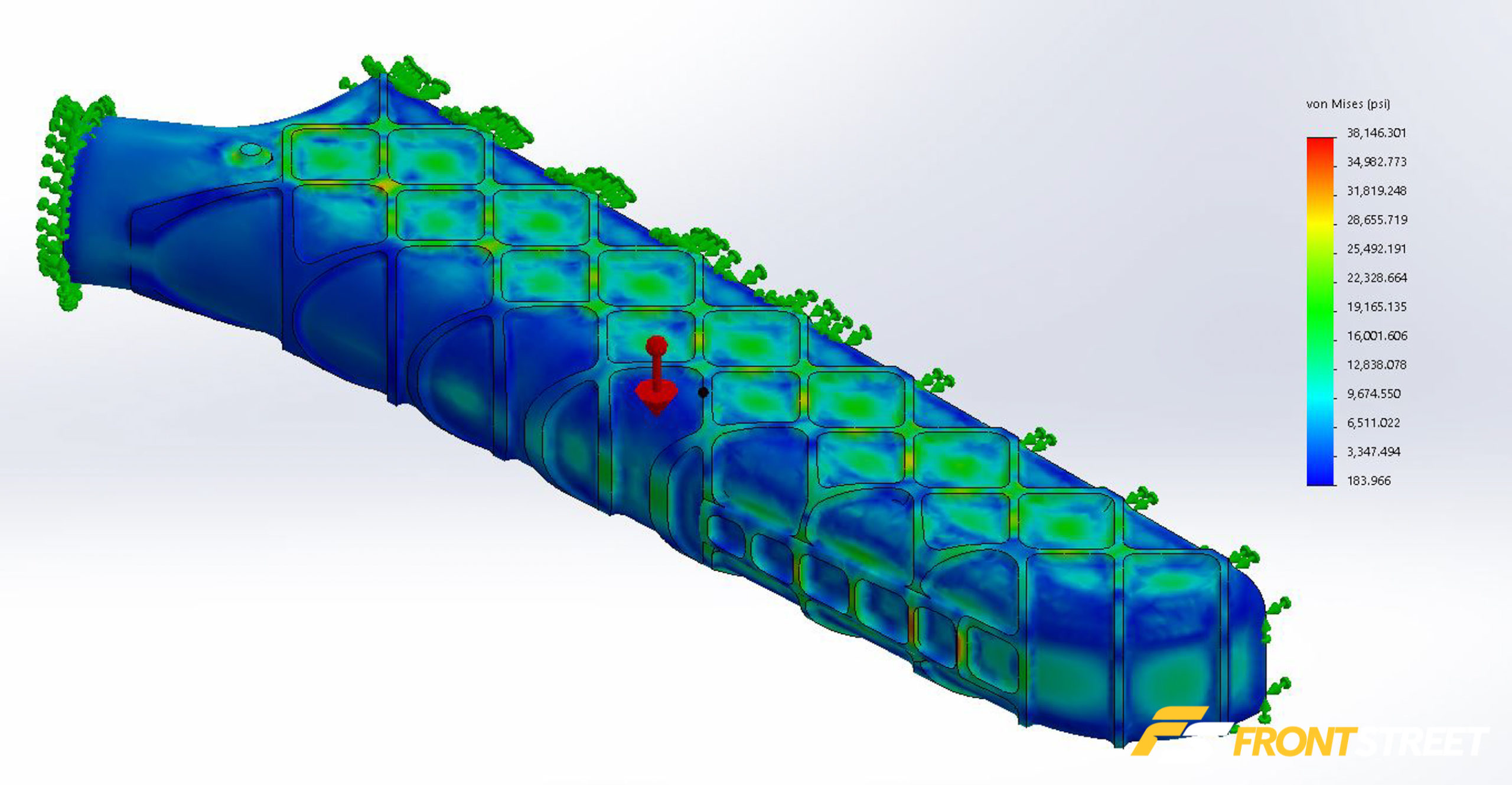

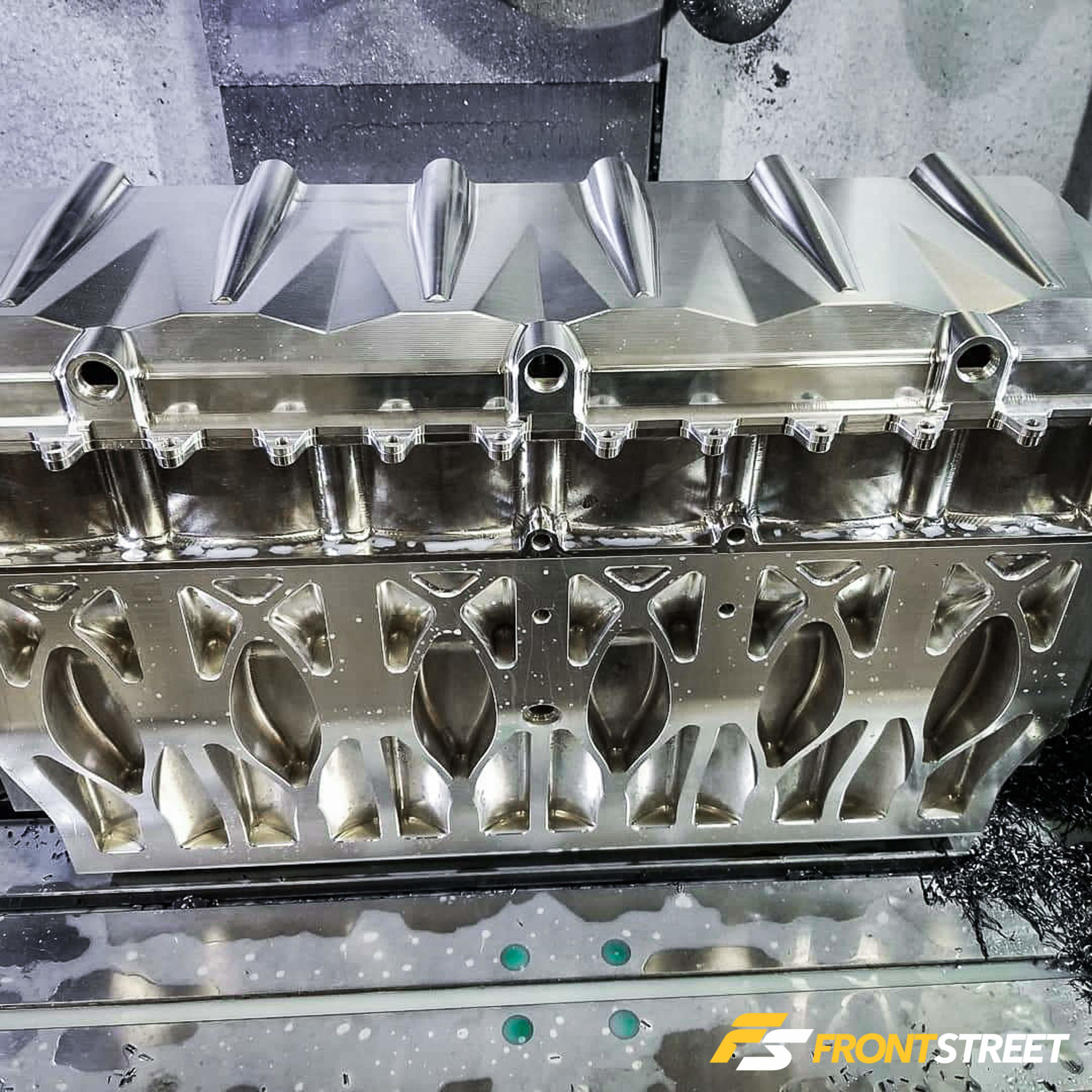

Customers also wanted stronger and lighter components, so Finite Element Analysis (FEA) was engaged to design the bulletproof billet aluminum cylinder block. The design employs aluminum for the main block, and steel is used for the bed plate. The use of the FEA software allowed them to remove unnecessary material while reinforcing the critical points with a new web design that not only looks great but is 100-percent functional in the high-demand performance arena. The new design uses six studs per main with two inches of 5/8-inch thread engaged in the block. According to D&J’s Drew Pumphrey, the new design gives them over a million pounds of clamping force across the bed plate and block.

As a proof of concept, they built the Executioner, which is a 408 CID (4.212 x 4.88) demonstration engine. Using the newly designed block and bed plate, they also incorporate a 4.88-inch stroke billet Winberg crankshaft along with D&J Precision’s own X-Beam 1-inch longer connecting rods, manufactured in-house. These are billet tool steel rods with pressure lubed wrist pins and ½-inch ARP rod bolts.

“We raised the deck height one inch to improve rod to stroke ratio,” says Pumphrey.

They also manufacture their own Forged Steel Ring Land pistons; 2618 alloy forged aluminum pistons incorporating a steel top ring land are used to provide appropriate support.

“After several years of development, we finally have a piston that can take the extreme cylinder pressure of these high-performance diesel engines,” says Pumphrey.

The Executioner further incorporates unique features to address all the performance concerns D&J has observed over the years. It uses a billet roller camshaft by Hamilton Cams for improved durability. The cam provides 216/232 degrees duration respectively, for the intake and exhaust. They do not specify a lift value at this time, which is code for “we’re not giving away all of our secrets.”

Cylinder head sealing is achieved with no gasket. To accomplish this, they O-ring all the oiling passages and seal the cylinders with a reusable spring-energized “C-ring” fire ring that originated in the aerospace industry. The compression ratio is 15:1.

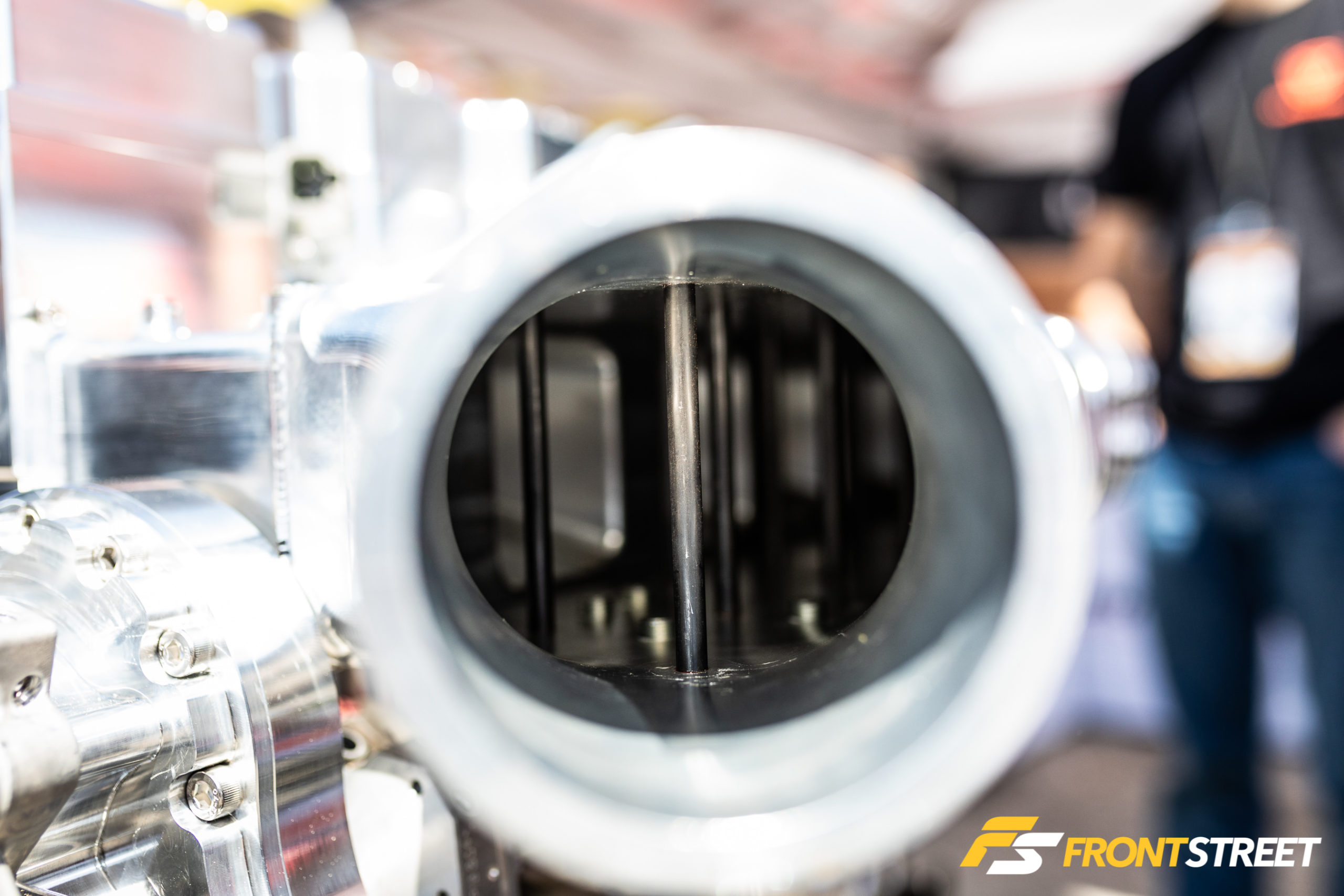

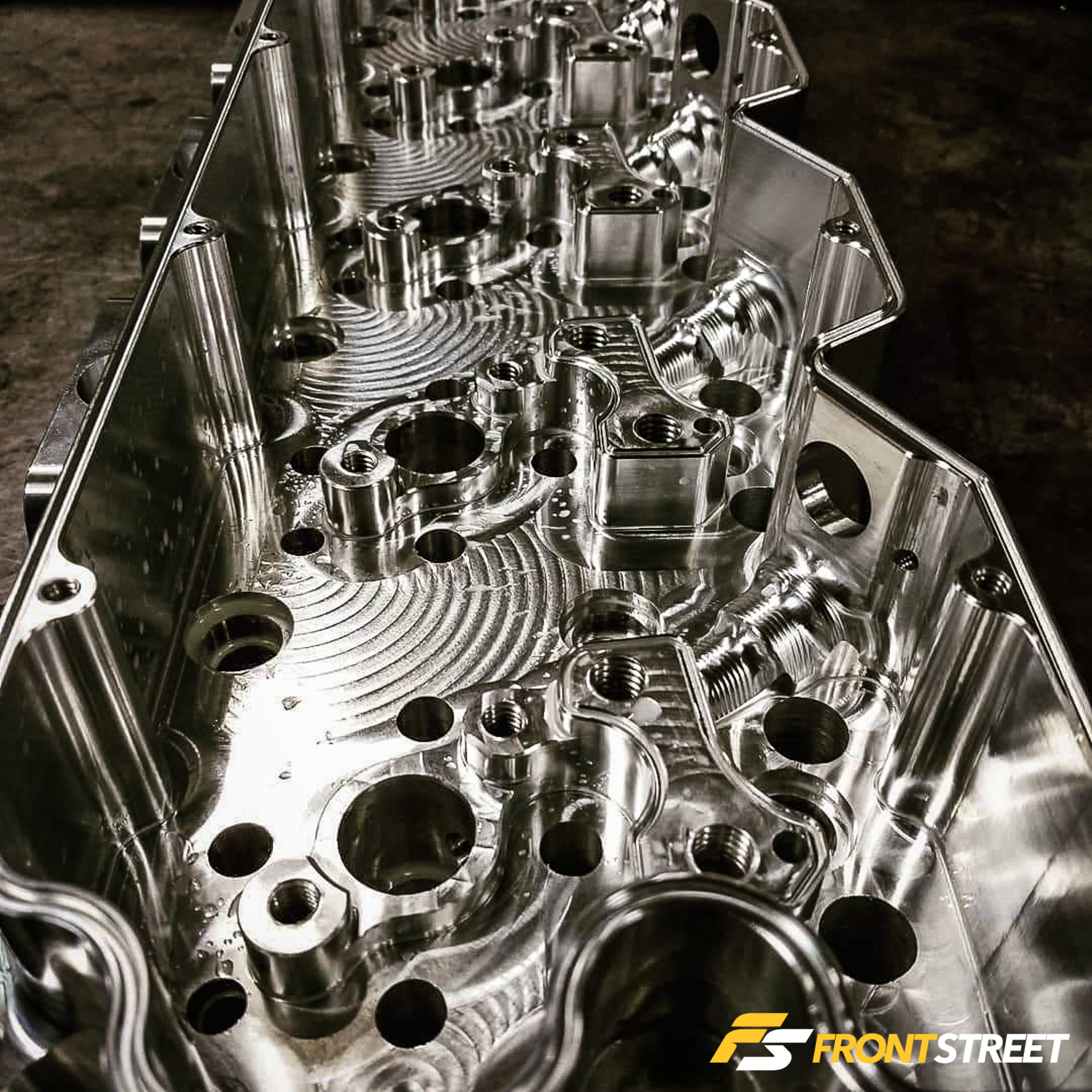

In conjunction with the design of the block, D&J also worked to develop its own 24-valve aluminum cylinder head, which is secured with custom ARP 625 studs with 5/8-inch threads in the aluminum block. All fastener threads in the block and the cylinder head are roll-formed to ensure the strongest engagement possible. Combined, the cylinder head assembly, valve cover, and intake assembly weigh 85 pounds less than a stock assembly. The cylinder head uses Ferrea Super Alloy valves that are finish-machined in-house; the intake valves measure 1.65-inch, while the exhaust valves are 1.5-inch in diameter.

Particular care was taken to design the lightest and highest flowing head on the market, and they have realized that goal. The manifold was also part of that objective, and it had to weigh less than ten pounds. The system not only had to be the lightest, and it had to flow well. Critical design considerations also included the ability to promote even airflow and withstand up to 200 psi of boost pressure in racing applications.

A full week of FEA design and revisions were required to realize these ambitions. They were not happy with the initial exhaust port design, and after several revisions ended up with a Patent Pending design for the exhaust ports in their exclusive head. The proprietary new design incorporates an individual exhaust port per valve, giving the cylinder head 12 exhaust ports for the 6-cylinder engine. This unique design yielded an additional 100 CFM of exhaust flow—critical to promote maximum performance.

D&J also designed and manufactured an all-new exhaust manifold to accommodate the 12-port cylinder head. The header is machined from billet steel and welded together, and leads to a T6 turbo foot. Twin wastegates will be used to control boost pressures.

A new billet timing gear housing was also designed to eliminate the need to run belt-driven accessories. All of D&J’s accessories—including multiple high-pressure fuel pumps and the oil pump—are gear-driven for reliability. Moreover, every part of this engine was designed and manufactured at D&J’s facility in the United States of America.

“We designed every part in this engine for maximum performance and durability from oil pan to valve cover, front timing gear housing to bellhousing, and the intake and exhaust manifold,” says Pumphrey.

During their first test session, they gathered a formidable team of experts. Since the Executioner was, in effect, a new and untested engine, they wanted not only to test the limits but also to do so with the most knowledgeable people available. Some of the best people in the industry contributed to the development of this engine. Phil DeVries at Exergy Performance helped every step of the way on all aspects of the fuel system and engine calibration, using a Bosch ECU and Powerbox setup.

“Without him, we could not finish this project,” says Pumphrey.

Fluidampr was also brought in to evaluate engine harmonics.

“Since this is essentially an all-new engine, we wanted to make sure their damper is properly tuned for our application,” he says.

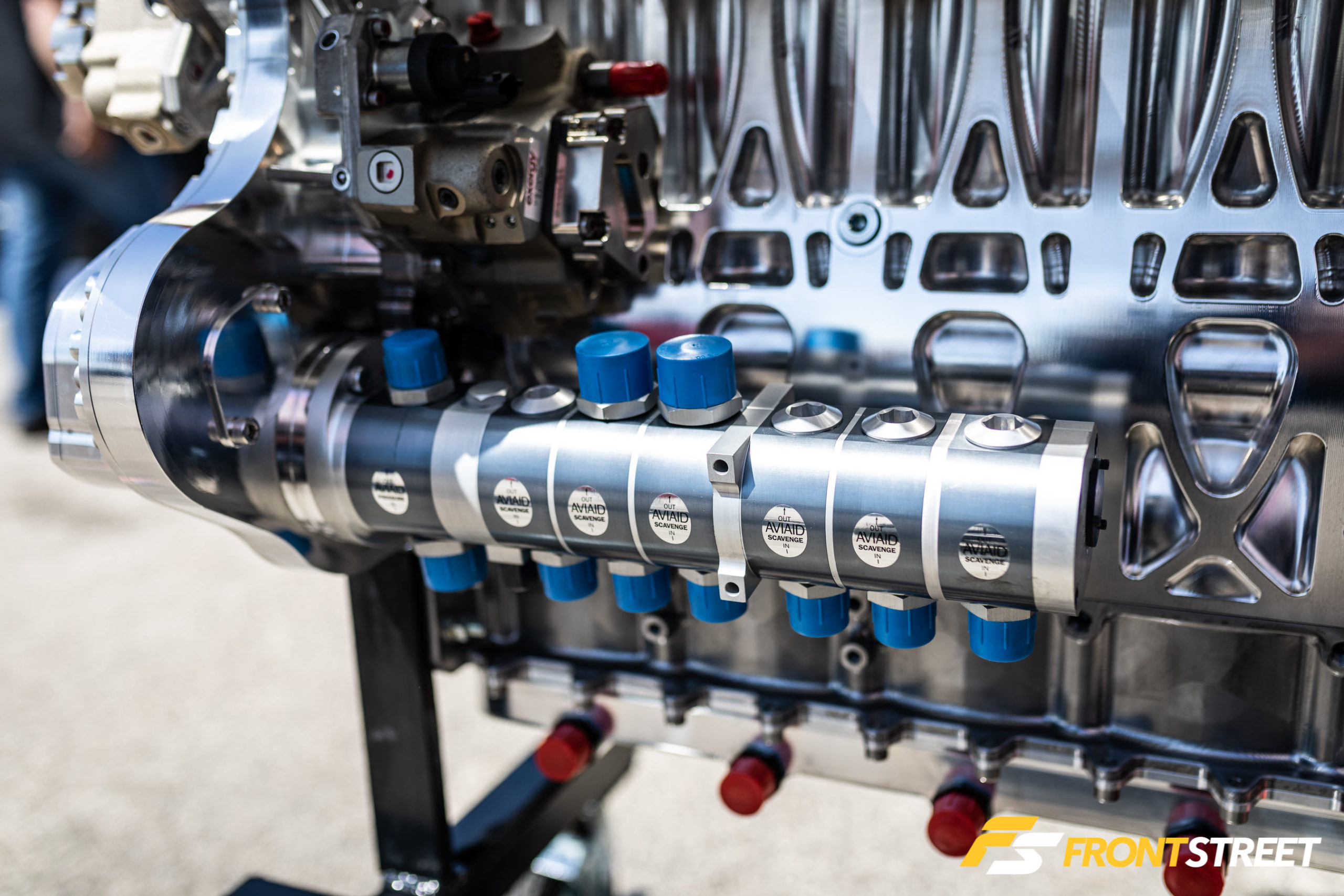

For reliability and peace of mind, an Aviaid dry-sump oiling system and Hot Shot’s Secret racing oil was trusted to supply and distribute all the essential lubricants.

A Bosch ECM controls the fuel system with a wiring harness by Exergy Performance. The fuel injectors are Exergy CRIN3-22 650% over with dual Exergy race 14mm CP3 fuel pumps, fed by an Aviaid fuel pump section on the Aviaid oil pump.

D&J also worked with Kistler Engineering to measure real-time in-cylinder pressure and gain valuable information no one has ever seen in a high-performance engine at this level.

Pumphrey’s philosophy: “It helps us design better parts for more durability as well as develop tuning strategies that will help save parts. Our goals are to make engines that will take the abuse that Customers like Firepunk Diesel put them through. We ended our test session with over 3,200 horsepower and over 3,300 lb-ft of torque.”

The Executioner is going into the Save The Racks Pro Mod Chassis raced by Firepunk Diesel for 2020, boosted by a single GT55 turbocharger and nitrous. Water injection pressurized by the nitrous tank helps to cool the mixture. It utilizes two spool jets and three stages with the Bosch ECM controlling Nitrous Express solenoids and a fogger system.

The Executioner is essentially a Cummins 6.7-liter diesel completely reinvented and redefined for drag racing. Performance at this level requires absolute attention to every detail, and D&J has seen to that and more. As diesel racing moves into a new and evolving era of ultra-high-performance, D&J Precision Machine is helping to lead that advance. No doubt, some of that developing technology will eventually spill over into higher demand street and towing applications as well. This killer engine leaves no opportunity unexplored.

As outfitted in the S-10, the Executioner makes use of many feet of aluminum tubing and HD quick release clamps from Front Street sponsor Vibrant Performance, along with boost control products from our sponsor Turbosmart. Firepunk’s Lavon Miller says they have plans to use Turbosmart’s new electronic wastegates in competition this year.

“We have enjoyed working with Drew for almost 10 years. His drive for innovation and providing proven results has advanced our team’s goals year after year,” says Miller.

Keep an eye on the Firepunk Diesel YouTube channel in the coming weeks for more on this insane beast of an engine.