I first met Jason Terrell and Brad Schnieders of Tin Soldier Race Cars at Duck X Productions’ No Mercy X in the fall of 2019, and we immediately hit it off. I was drawn to their pit area by the gorgeous white Mustang and had snapped most of these photos before they even realized I was there. Once we got to talking, it felt like we had been friends forever. I discovered that although their Limited 235 car is quite impressive in its own right—with a stock block, stock-headed turbocharged LS engine that runs at the front of the pack in the class—the Tin Soldier story was the real story here. It’s a story about a friendship, a dream, and being in the right place at the right time. That resonated with me in a big way, as it somewhat follows a parallel arc to my own in the performance industry.

When I called Jason to go over the details for this article, I fully expected to learn a bunch about the car and why it performs so well. Instead, he told me a story about the people who helped the car come to be, which is the real secret to why it does so well. Sure, the car is impressive—and I’m not trying to downplay that as it is the record-holder for turbo cars in the Limited 235 class—but the pair’s attention to their craft and the idea they had to start Tin Soldier Race Cars is what sticks out in my mind as the essential part of the equation.

Terrell is a second-generation drag racer; his father, Ron, is a well-known NHRA Super Stock racer and the inspiration for the business name.

“You can’t talk about Tin Soldier without talking about my dad,” says Terrell.

“My dad started drag racing in the ‘60s; he wanted to run Super Stock, so he bought a ’69 COPO Camaro from a guy that had bought it from the showroom floor who thought the motor was blown up. Dad went to look at it and saw that the plug wires were crossed. I think he bought the car for $500, and it was a real COPO car. He ended up getting it tubbed and put big tires under it, and at that time, he named the car ‘The One Tin Soldier’ after a song that spoke to him. He’s 77 and still races NHRA Super Stock; last year at the US Nationals, he qualified fourth out of 160-some stockers. He’s still a bad dude in his own right.”

He loved spending time with his dad at the track but wasn’t a huge fan of Super Stock-style racing. He spent time behind the wheel of a junior dragster—which was, in his words, boring—then raced motocross until he was in his early 20s. Fast forward to several years ago, and his local track put on a heads-up event called Thursday Night Lights, which made him feel like drag racing was relevant to him again.

“I kind of fell in love with the heads-up stuff and started looking into it. I got hooked on X275 racing, and I didn’t even know anyone that did it. I would watch the videos on YouTube of the pioneers of X275, and from that, I started building a turbo LS third-gen Camaro in my garage. I had no idea what I was doing; I was just buying parts and trying to figure it out. I had a MIG welder that I was using to do stuff. I knew that I wanted nice stuff but couldn’t afford to pay someone to do it,” he explains.

Two classes in TIG welding at the local community college helped to provide him with those skills, which dovetailed nicely with the previous education he received in high school—two years of sheetmetal fabrication courses—and the hands-on training he received from years of assisting Dad with the Super Stocker.

“I got a job offer before I graduated; I never even completed the program. I was still messing with my stuff and started doing work for other people because racecar stuff is expensive. My wife and I had just gotten married and bought a house, and any extra money I could make was a plus,” he says.

A switch to another job got him in with a great company that was close to home. A Facebook message from Brad—who he was friends with on Facebook, but had never met before—asking some questions about welding technique set in motion a visit to the fabrication shop where Brad worked so that he could provide Brad with assistance on a welding project. And that, folks, is how Tin Soldier Race Cars came to be.

“Man, this is going to sound crazy, but I walked through the door, and the shop was really dirty and kind of dim-lit. There stood Brad in this dirty, grimy shop. He was just this bright light in this grimy place, and I just knew that we were going to go into business together. We began this friendship and started talking about fab work and welding all the time,” says Terrell.

“Someone wanted me to do a roll cage for him for a time attack car. Up until that point, I had been installing kits but had never bent anything myself. I asked Brad if he wanted to do it together, so we did this time attack car in my two-car garage. With my weld quality and Brad’s fitment, people started begging us to work on more stuff.”

Right around the same time, his job situation became unsteady due to fluctuating fuel prices—it was an oilfield job—and he was uncomfortable with the feeling of being the low man on the totem pole.

“I got some courage up and called Brad one night and said, ‘I feel like if me and you team up, we can start building some of the best cars in the country. We can do it.’ He felt the same way and said that we should do it. So I had Brad on board, but then I had to figure out how to get my wife on board, which was a whole different thing. I had to convey that I felt like God was telling me that I was going to be in business with someone I just met, and he’s on board, so you should be, too, ” he laughs.

She thought he was crazy, but he and Brad kept talking about it. Then, one night he had a dream that he was standing at the edge of a cliff, overlooking the water, and he kept looking over and sizing it up, then got so close to the edge that he tripped and fell down the hill into the water. Then the dream restarted to where he was back on the hill, took a running start, jumped, and landed in the water smoothly.

He explains, “I abruptly woke up and felt like I was at a point in my life where God gave me this dream that this was my destiny—that I could choose how I get there, by taking the leap of faith and do it, or kind of tiptoe around and end up in the same spot anyway. I told my wife [about the dream], and she said, ‘I think you’re crazy, but I’m in. But you can’t take any money from our household income to start this business.’”

With virtually no money, no income, some tools, and no place to work, he and Brad pooled the leftover money from the time attack build to rent a 1,200 sq-ft building that was $600/month—in the bad part of town—and in between where each of them worked at the time. With a plan to run Tin Soldier on the side for a couple of years, they signed on the line.

“If this dude would have had anyone else to rent the building, he would have rented it to them, but he had no other people that wanted this place. When we were moving in, he said to my dad, ‘If these boys can’t make their payment, are you going to cover their payment for them?’ He had no faith at all. We ended up renting this place, and by the time we paid the first month’s rent, security deposit, and to get the lights turned on, we had like $500 left. We went to Harbor Freight, spent the rest to buy everything else we thought we’d need to get this deal going, and we were in the race car business,” he says.

At 25 and 26 years old, respectively, the pair effectively bootstrapped themselves into existence. Their first paying job was from a local kid, Logan, who hired them to install a roll bar into his diesel truck, not necessarily the work they wanted to do, but work nonetheless. They went back and forth on names—at the time Jason was using Tin Soldier Welding for his personal Instagram page—and they decided to incorporate the Tin Soldier name. They liked the fact that it didn’t include either one of their names, had a little bit of legacy tied to Jason’s dad, and would allow them to grow the business into something more significant than the two of them alone.

The week they moved in and established Tin Soldier Race Cars in June of 2015, Jason, an ordained minister, was acting as the officiant in a friend’s wedding in Louisville. He was looking for something to do on Saturday morning before the wedding. The Prize Fight heads-up race was going on at Ohio Valley Dragway, so Jason headed over there to check out the festivities. With no business cards in hand, he walked around the track and showed off some photos he had on his phone to the various people he met, trying to drum up interest in the fledgling company.

He was looking for one particular person that he knew was supposed to be there—a gent named Kent—who helped someone with an X275 car. He found a pretty black Fox Mustang and walked over to look at it, and who should crawl out from underneath but Kent. It turns out that the car was owned by noted X275 racer “Fast” Jack Vanover, and the relationship he established with Jack as a result of that meeting catapulted TSRC into a position where Vanover commissioned the team to build him a new car for X275 competition.

“We worked with Jack and started putting together Serial Number 0001 car. We had done roll cages and stuff, but at this point, we’re building a chassis, doing the suspension layout, moving stuff around, and doing a lot with what Jack had already learned,” says Jason.

Sadly, before they completed the car, Jack passed away from a heart attack, but Terrell, Schnieders, and the TSRC team are forever grateful for the doors that opened up for them as a result of their friendship with Jack. In fact, at Jack’s funeral, they met racer Martin Connelley, who took up for Jack and continued to open doors for them. Connelley facilitated the introduction to Mark Menscer of Menscer Motorsports, who had seen the car they were building for Jack and was extremely impressed with its quality.

“He believed in us as businesspeople and racecar builders. Mark’s been a really good friend to us, and a mentor. One of the reasons our cars work so well is that we have such an awesome relationship with him,” he says.

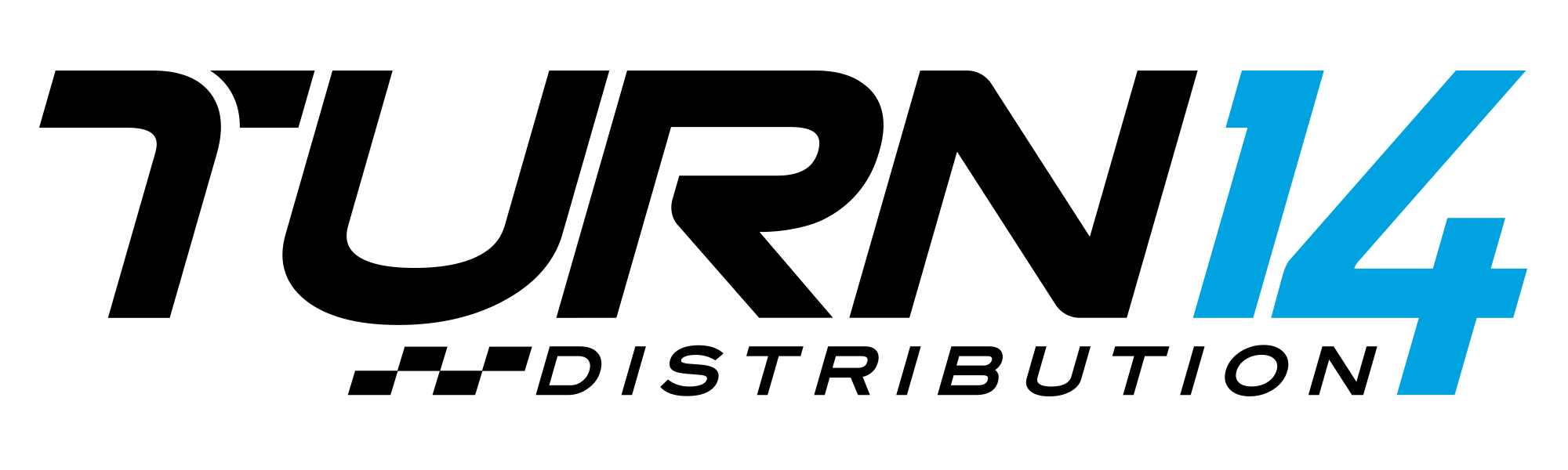

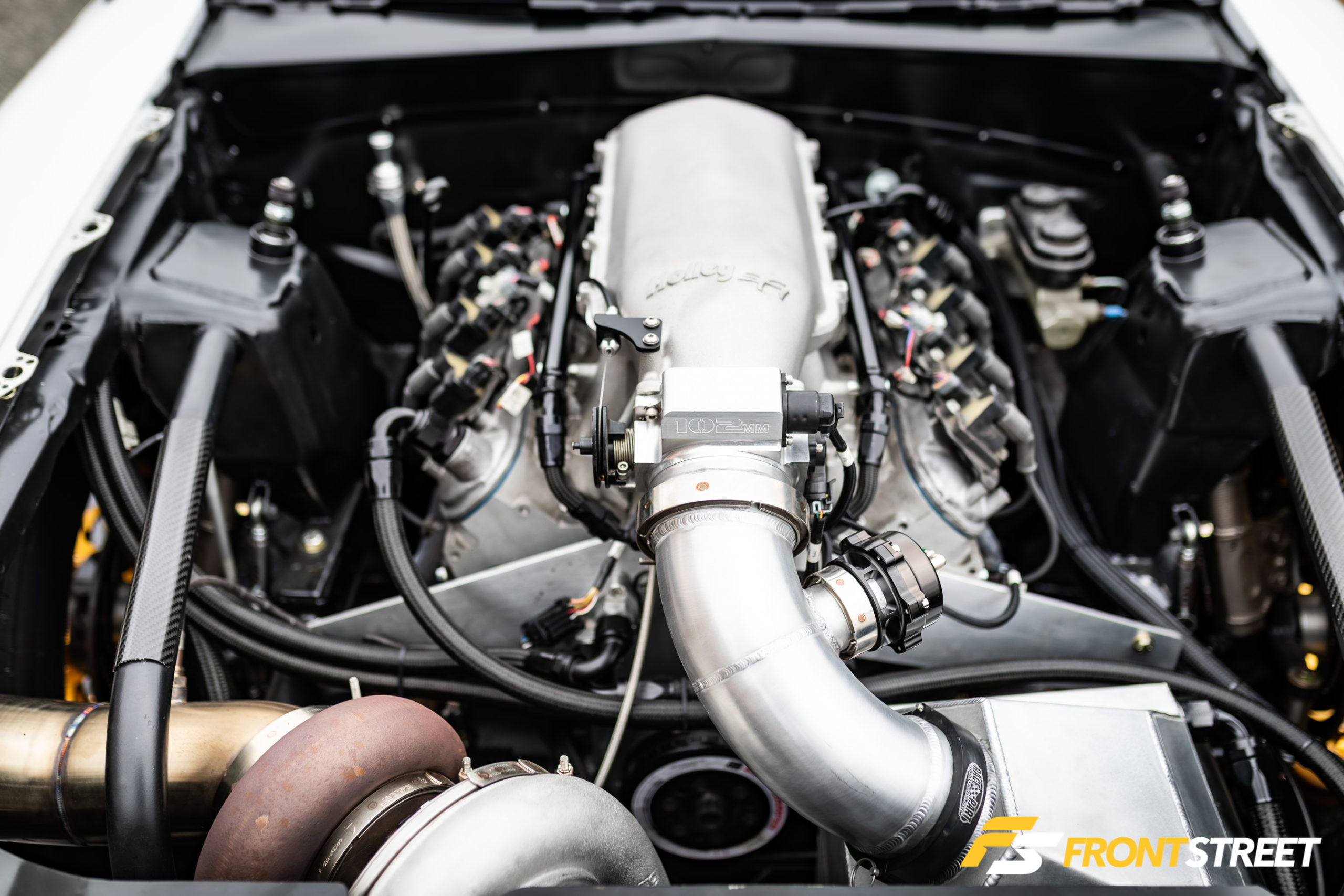

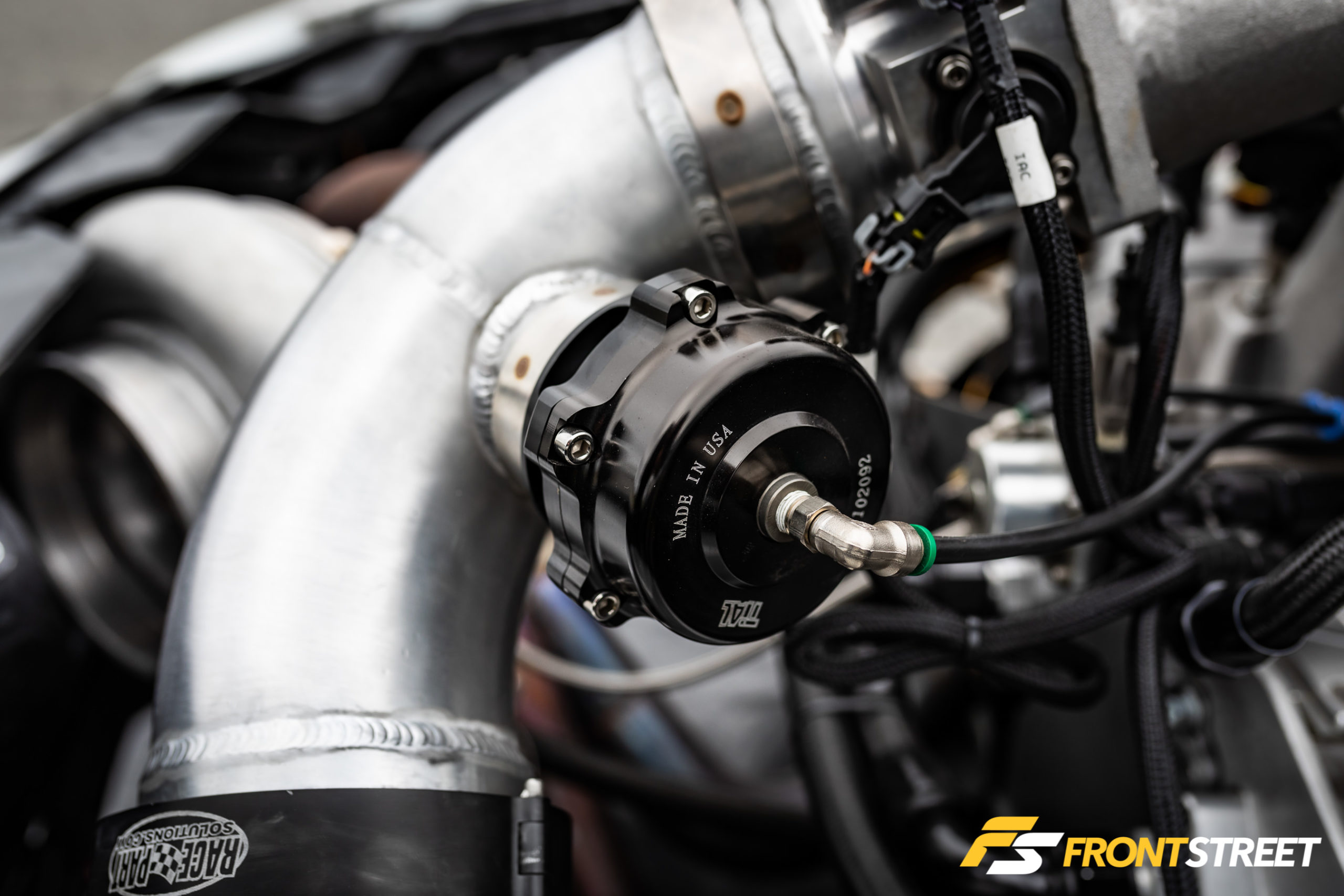

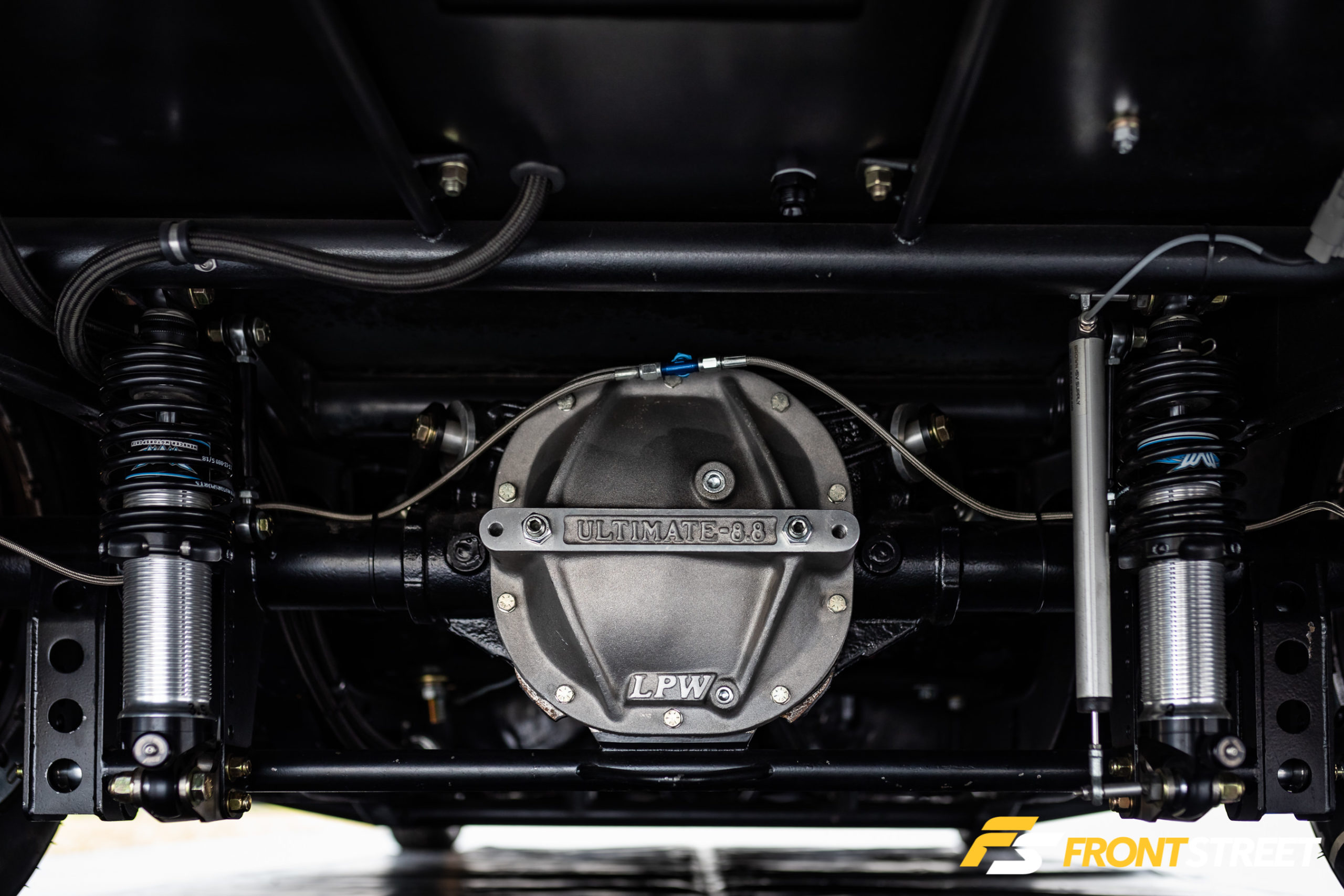

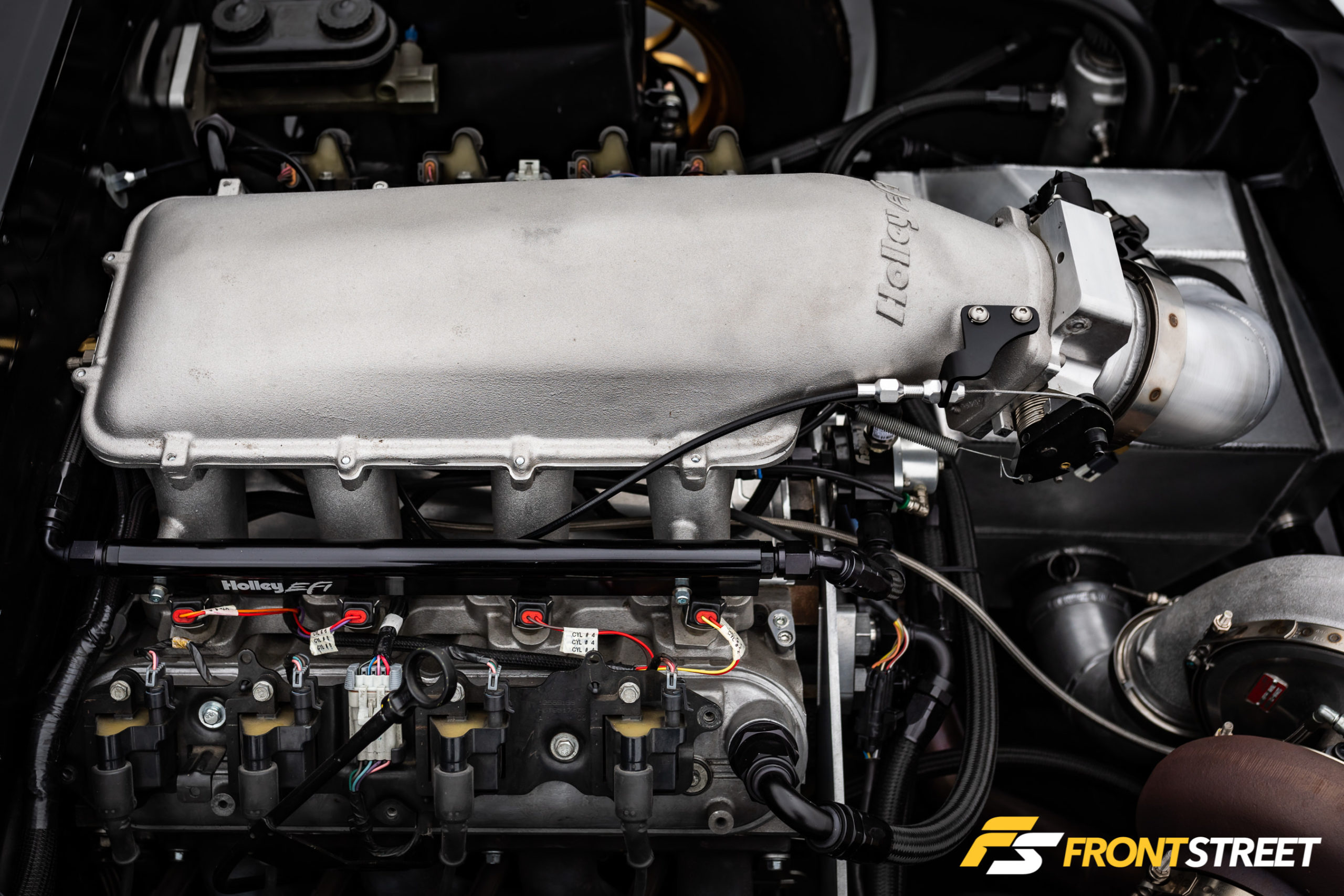

The Mustang is a total budget build, designed to show off the team’s talents without bankrupting them in the process. If you can believe it, the engine is based entirely around stock LS engine parts, from the stock 6.0 block to the truck cylinder heads and 4.8-liter crankshaft, they’ve got a total of about $4,500 into the long-block—and it’s currently the quickest turbocharged car in the Limited 235 class at Duck X Productions races. They use the vehicle for parts development and to test new ideas, with the majority of its development and assembly performed in-house, with critical items like cylinder head porting farmed out.

Since its inception, Tin Soldier Race Cars has moved three times, settling into its current 4,000 sq-ft, busting-at-the-seams home in Covington, Kentucky. Jason says the company’s line of race car parts has taken off in a way they never expected; in just over a year, they’ve turned the parts side into 30% of the company’s business, and over time, they hope to flip that equation to reduce the number of cars they build. That transformation will likely require yet another move to gain more capacity in the building, but it’s a change the six-member Tin Soldier Race Cars team is ready and willing to absorb. After all, the company’s entire existence has been about change, and the uncertainty of facing the unknown challenges their spirit.

Jason sums it up simply: “I want to inspire people to dream. When you’re a kid, everyone tells us that we can do anything in the world, but we get to 16, 17 years old, and people start to tell us to think logically, which is a pile of crap. We have to keep dreaming, looking way outside the box, and doing things that nobody else thinks that we can do. I want our story to be something that inspires people to chase the things that are buried inside of them.”