Photography by Jeroen Willemsen

In the past, I’ve discussed how automotive enthusiasts tell ourselves we’re going to take it easy on a new car, then things change, and all-out project car builds ensue. Today’s story is slightly different because Klaas van Schaijk’s incredibly spotless 1983 MK1 Volkswagen Golf GTI didn’t start with meager plans. That didn’t prevent it from becoming the involved high-class build it is today.

Klaas got into the vast world of automobiles more than 20 years ago, when he started an automotive club with his friends named VW Team Maasdonk. From there, he grew into the culture and absorbed as much of it as he could. It wasn’t until he and his friends all aged in unison and their hobbies and interests shifted that everything else changed. As the team’s passion began to falter, the Netherlands native sought to connect with like-minded enthusiasts who still shared his intense admiration for Volkswagens.

“I joined VW Team Brabant, and things got out of hand,” says Klaas.

“When you gain friends out of the [local] scene and go to meetings, then you see things you can do to your car, and that inspired me.”

The combination of camaraderie, influential passion, and the team’s undying development of quality builds meant that Klaas’ Volkswagen dreams were about to become elevated to a new level.

Before Klaas’ ownership, this 1983 Volkswagen Golf GTI lived its life as a workhorse for a local hobby racer who utilized the car for years as a sporty daily driver alternative. Klaas located the vehicle 15 years ago stored in a barn in its original condition, a far cry from the showstopper it is today.

“When I found this car, I had just started my own company as a gardener. My father told me that I couldn’t do both at the same time. That was my motivation to prove that I could do it,” says Klaas.

“At first I wanted to do ‘German-style,’ but because of how long it took to build, I fell in love with the original looks, and plans changed. The original 1.1-liter engine was removed for a GTI DX engine with Weber [carburetors], but when I went for a drive with my dad, it really drove like sh*t. Instead, I wanted an engine with a computer, so I can easily adjust it.”

To update the powerplant to a unit that can be tuned and adjusted using engine management software instead of traditional carbureted tuning techniques, he enlisted Carlo Hulsen of Hulsen Turbo Tuning (HTT) in Veghel, Netherlands, to supply a solution.

“He told me that he had a TFSI engine, so we made plans that it had to make more power than original but with the stock internals. This complete build took about two years,” says Klaas.

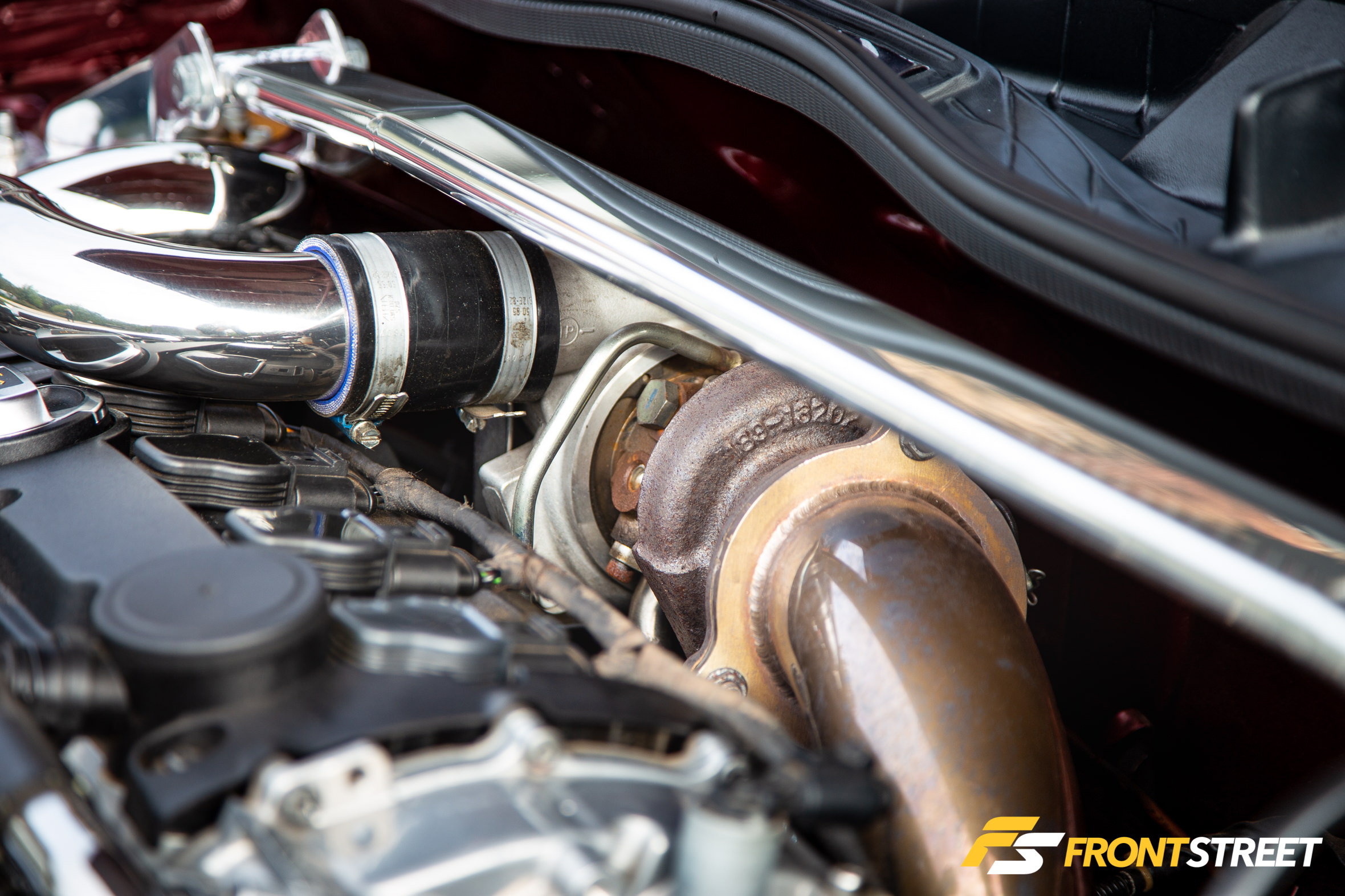

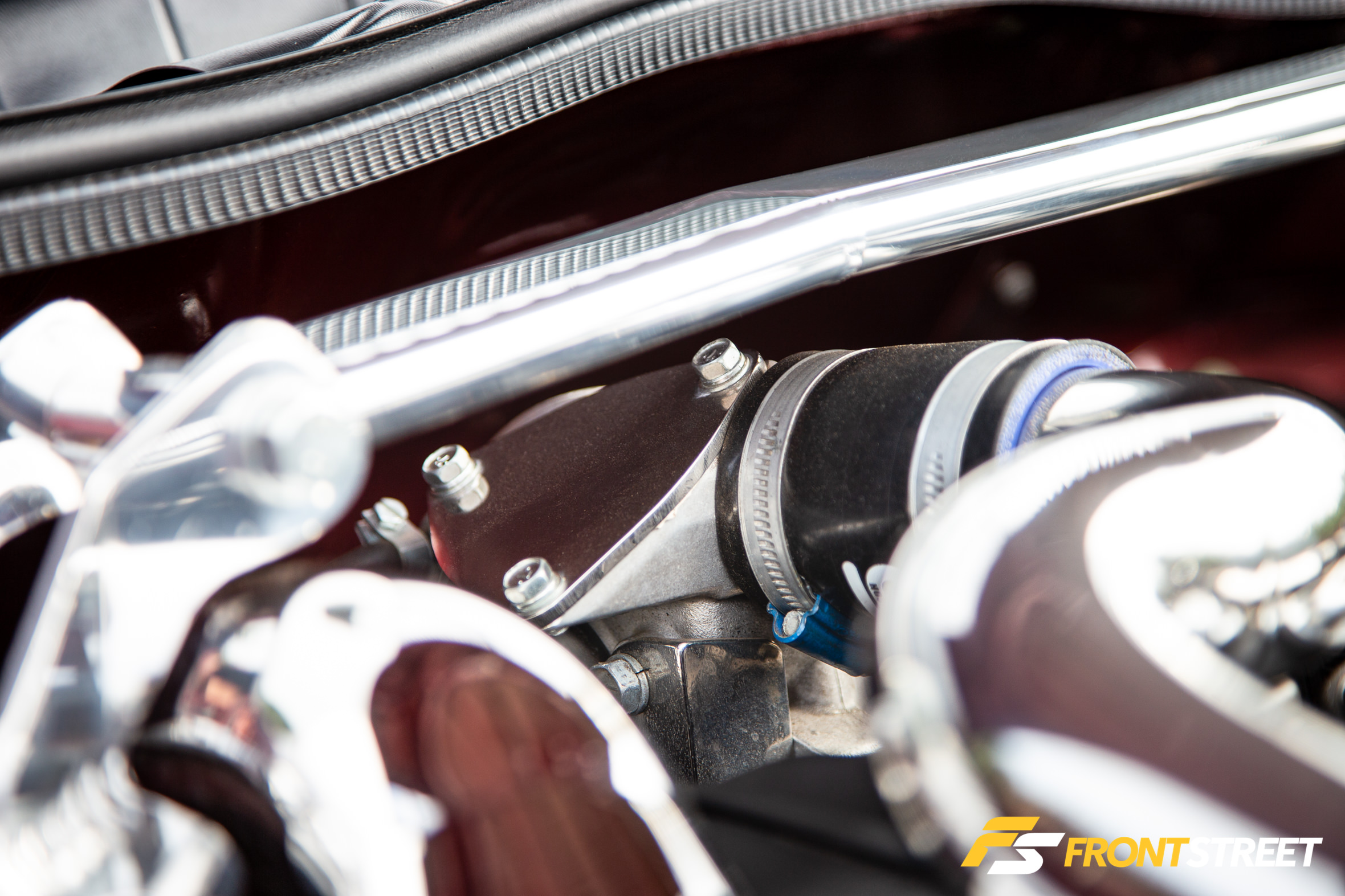

Utilizing an MHI 19T turbocharger mated to Volkswagen’s new turbo fuel stratified injection (TFSI) engine out of the MKV GTI meant that precise engine management was necessary to process the forced lean mixture entering the combustion chamber. HTT sourced KMS Kronenberg engine management to keep the mix and spark operating as desired. The juice is squeezed through an OEM VW Corrado G60 drivetrain and into the front wheels.

Johnny Walters of Walters Las & Montage helped facilitate the engine’s breathing apparatuses by creating a custom intake manifold, turbo manifold, and Supersprint downpipe. The spent gases process through a Powersprint muffler customized by Walters before exiting into the atmosphere.

Anyone who has seen these cars in real life knows how small they are when compared to their newer MKV variant. So, how does such a large modern engine fit inside the classic chassis? Well, it kind of doesn’t. Numerous areas of the car needed modification to house the engine properly, and even after that, there was still the significant deck height issue.

“I had a problem. Because of the low engine, I couldn’t drive low. So, I went to Jeroen Leenders for air ride,” says Klaas.

A fellow VW Team Brabant member and regional Air Force air suspension source, Leenders chose an air ride system with four valves and ride height sensors to sort out this issue. But it wasn’t as simple as bolting it on and enjoying the addition. This setup was crucial to delicately carve the fenders overtop of the celebrated BBS Motorsport E50 wheels. They took a lot of time and care to make sure the suspension and wheel setup mated in perfect harmony.

“The wheels I found at Felgenpoliererei Gescher / Zero RS Gescher, a good friend of mine from Germany, who specializes in zero lip wheels,” says Klaas.

Electing to run a non-staggered 17×6.5-inch wheel on the front and rear presented some difficulties. However, when combined with the +45 front and +20 rear offset, and the ‘zero lip’ matchup of multi-piece elements, perfectly fitting these wheels becomes a whole new ballgame. Klaas chose to wrap the legendary motorsport wheels in 165/35-17 Nankang Ultra Sport NS tires to aid the setup’s fitment and grip.

The build’s overall turnout was shaping up impressively, but the most challenging aspect of it remained: the paint. Klaas had a few different options in mind for color but knew he was taking the vehicle to Ricky vd Hanenberg to master the paint’s application. After some time to process his choices, Klaas went with Rubino Red, a color better known for enveloping vehicles from the Ferrari stable.

“I decided on the color because the car was already red, so I didn’t have to adjust the paperwork. I also had a choice of bleu with the same paint effect,” he says.

In addition to the new paint, Klaas located and installed Wobshop headlights, KM Works side mirrors, and called his friend ‘Showhan’ Zijlmans for a set of chromed metal bumpers to complete the exterior.

The vehicle received Porsche seats, newly upholstered original door panels and dashboard by Smits Stoffeerderij, custom carpeting, and even a Becker ‘Mexico’ radio. A host of gauges located under the dash—including oil pressure, oil temperature, and boost—helps keep levels in check while driving.

Although being married in the car ranks highest on his list of memories associated with the build, he recalled a moment with his dad as another main highlight.

“The first drive in the car with my dad on the highway, I took the highway two times. His face was unforgettable!” he recalls.

“I’d like to thank Carlo Hulsen (engine), Ricky vd Hanenberg (paint), Geert de Veer (took the car apart), Johnny Walters (welded the custom parts), Boris Westerbeek (the cable guy), Dirk Wierczeyko (wheels), Jeroen Leenders (Air Force air ride), Chris Muller (De Detailschuur), Ria van Schaijk (my wife and mental support), and Nico van Schaijk (my dad, welder, and parts).”

With the exterior and interior finished, the engine installed, and the air ride and wheels fitted, we now arrive at the vehicle’s current state. Almost seven years after the work initially began, Klaas van Schaijk can look at the masterpiece that he, his family, teammates, and friends created with pride and accomplishment. They’ve created one of the greatest MK1 Golf GTIs to date, and it all happened because things got out of hand.

[table id=29 /]