One of the best perks of my job is getting the opportunity to tour top-notch facilities in the automotive aftermarket industry. These are the well-oiled machines that keep our machines running like well-oiled machines. Some of the facilities I’ve traveled through have been around for decades, some design products for our favorite OEMs — creating clearance-level issues when I tried to photograph certain items. Others have gorgeous showrooms combining spotless project vehicles and client hospitality centers. Rarely do brands integrate it all into one modern workspace with a flair for fun like I encountered while walking through Mishimoto’s sophisticated headquarters in New Castle, Delaware.

Mishimoto is a brand that needs no introduction. Since 2005, the company has been at the forefront of automotive modification, establishing itself as the world leader in performance cooling. It has since branched into various networks of performance solutions for an extensive range of vehicles. Whether you’re looking to dress up your interior, prevent catastrophic oil vapor blow-by, or lower any multitude of fluid/air temperatures across your vehicle, Mishimoto produces something for you. Follow along as we walk you through the company’s headquarters and its research, development, and engineering center positioned next door.

First, we would be touring the 27,000 sq. ft., state-of-the-art engineering studio next door to the HQ as we needed to meet with our guide for the day, Mishimoto’s Sales and Marketing Manager, Ricky Nietubicz. After being buzzed in, a rather unique cooling-clad security guard greeted our arrival — and gently coerced us to test our temperature before entering. This sculpture is an excellent symbol for the innovative, creative, and out-of-the-box thinking that makes Mishimoto and its staff special. It’s also the type of automotive recycling you’ll see throughout the tour that sets the facility’s mood.

From there, we moved upstairs, where hand-welded exhaust tubing and chains guided us to the second level, but not before a giant waterjet-cut Mishimoto sign welcomed us on the landing.

On the second level, we entered the lounge and breakroom area for the Marketing, Sales, and Creative departments — all of which are situated just over the wall and overlook the shop area below.

Notice how everything becomes repurposed in this office? Whether it’s using empty barrels of the company’s synthetic coolant solution, Liquid Chill, as a magazine rack or measuring safe social distancing using Mishimoto product sizing, there was something clever everywhere we looked.

Moving back down the stairs, we noticed Mishimoto-branded BMX bikes in the hallway, free for anyone to use when traveling from building to building.

This is where the immersive product imagery is taken for the brand. Anyone familiar with Mishimoto’s goods has undoubtedly seen its website with varying overall and detailed images of every product it manufactures.

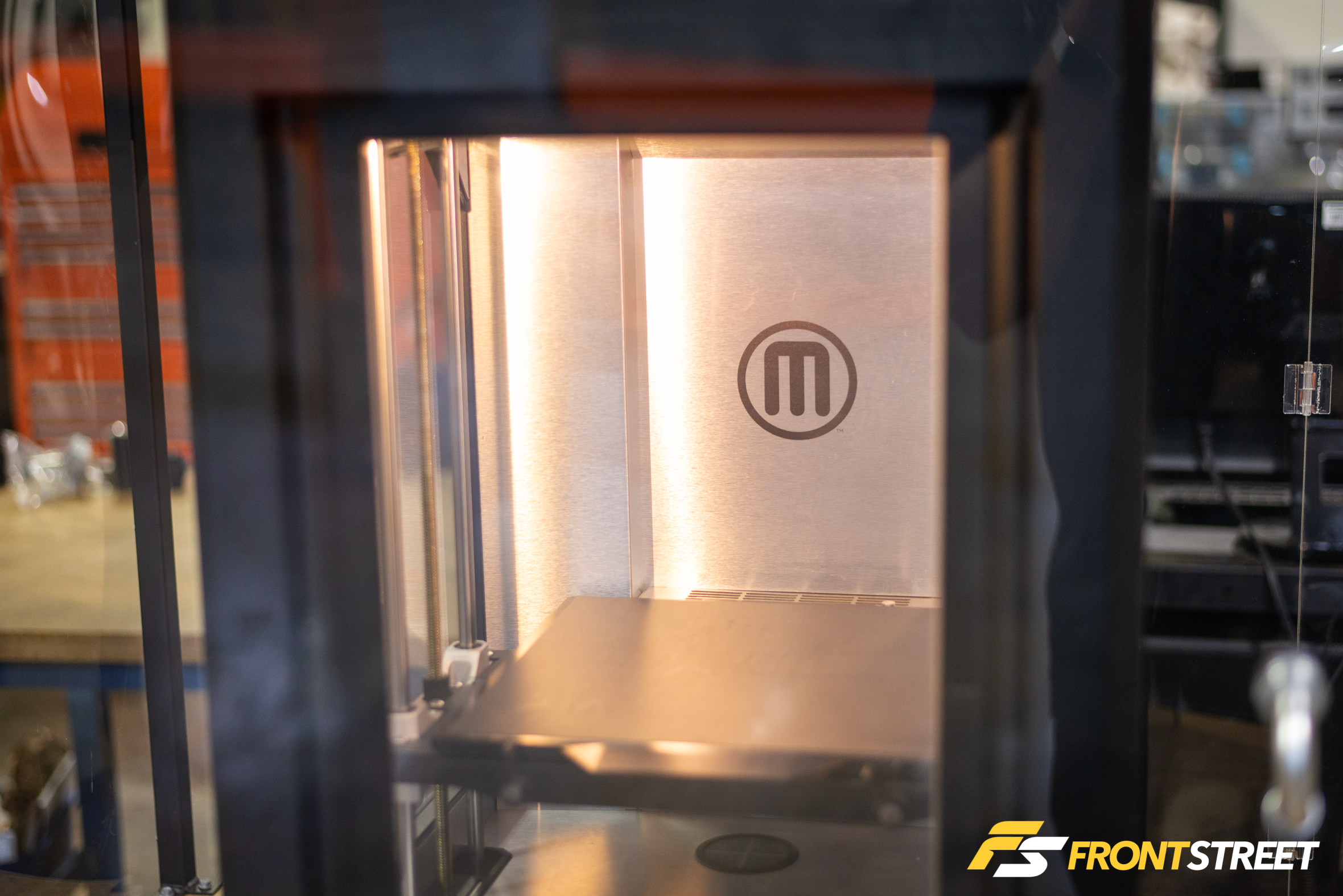

Now out in the research and development center’s open space, we could see the different tools and machines used for prototyping, designing, developing, and rigorously testing new products. A row of 3D printers awaits a full staff of trained engineers to make the prototyping process more straightforward, while on-site testing machinery can create harsh climates in a controlled environment. Oh, and the innovative automotive-themed solutions didn’t end in the other rooms. Even tubing and fluid delivery pieces get recycled into easy-to-use handles on the printer’s doors.

Speaking of engineers, the brains behind ensuring the renowned products fit and operate correctly are ideally positioned, each with their own lift and mechanical workspaces. This setup gives the Mishimoto staff of engineers the ability to design a product, prototype it in real life, test and install it, all without leaving their zone. That’s efficiency!

The test vehicles in the shop area that day were a Toyota GR Supra, Ford Raptor F-150, an FK8 Honda Civic Type R, and a few different heavy-duty trucks. However, what stuck out most was this road-tested JL Jeep Wrangler equipped with a prototype snorkel offering from Mishimoto’s new truck-focused brand, BORNE Off-Road. Look out for similar products from this outfit in the future.

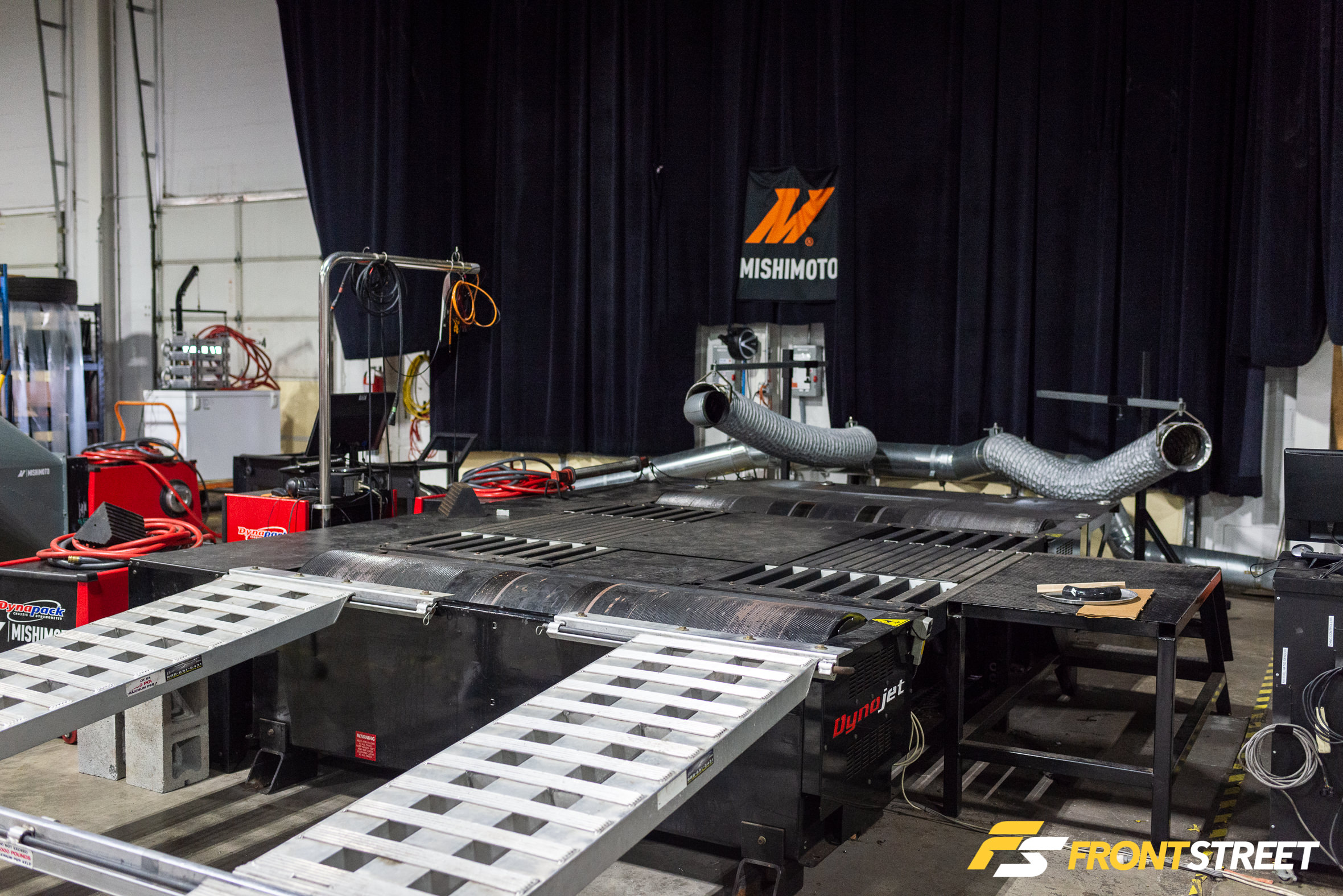

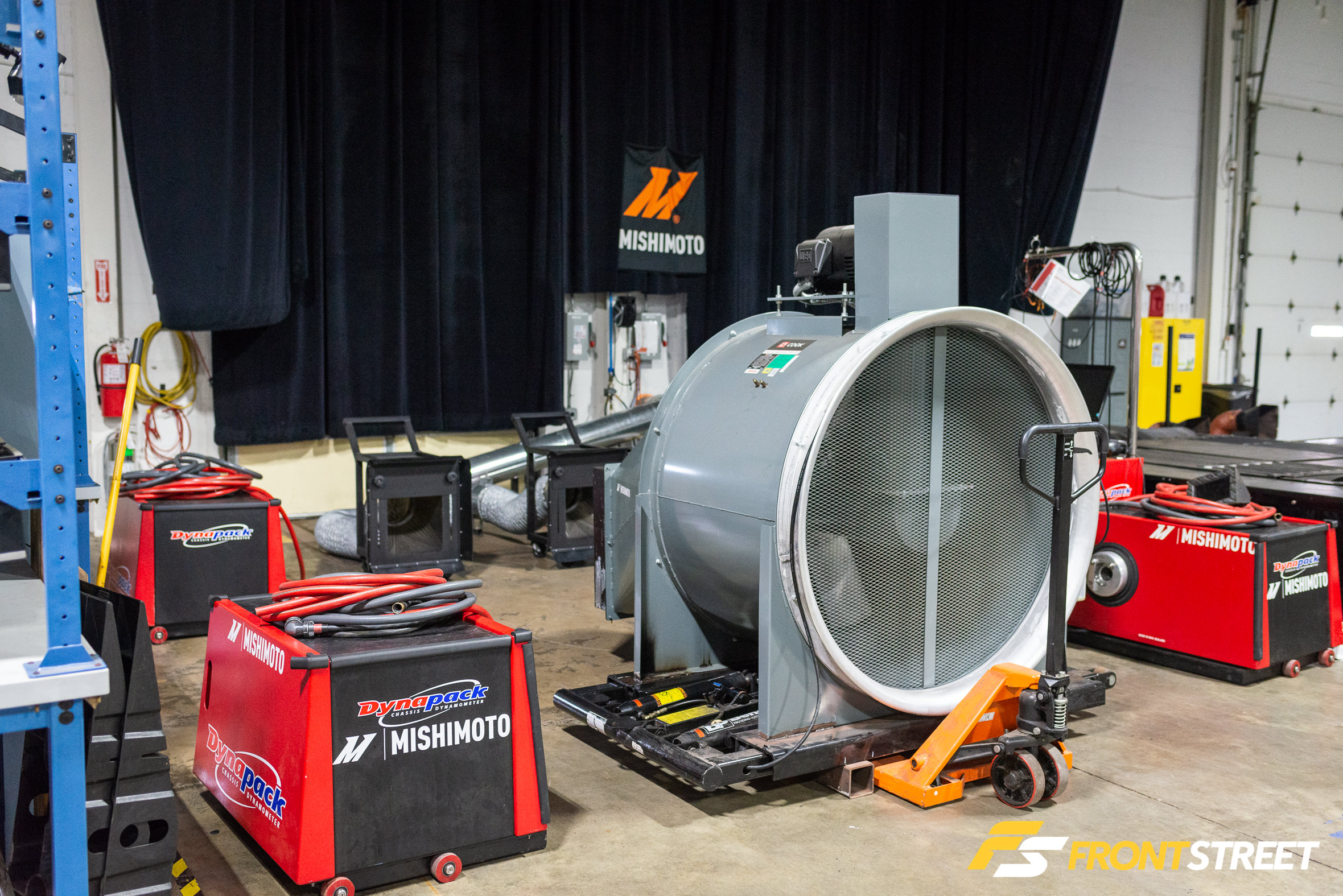

Next, we locked eyes on a duo of AWD dynamometers — both the mobile Dynapack and a Dynojet in-ground variant. Some might ask, “why have both?” Each has advantages and disadvantages, and most companies seem to compromise by using one or the other, but Mishimoto is fortunate to have the space and resources to have both on hand. So, their answer is “why not have both?”

The machinery used for additional prototyping and testing duties showcases some real innovation by the Mishi team. For example, something like a dyno likely comes with some sort of a cooling apparatus that requires a wasteful constant flow of cooling liquid like water, but when cooling is what your company does best, you create your own solution. Utilizing products they had on-site and a little bit of ingenuity, team members crafted this exquisite series of bar-and-plate intercooler cores, which is submerged into cold Liquid Chill and constantly pump water throughout to keep equipment temperatures in check for long dyno sessions.

The same team developed a similar option for the in-house waterjet situated nearby. Evidence that the decor was made in-house, the remnants of most of the building’s furnishings — including the endcaps of the office’s protection beams — found a home in the scrap pile of the waterjet.

Now, onto the office area inside the R&D facility. This glass-windowed, ultra-modern chamber houses the employees of Mishimoto’s Product and Video departments. Notice how perfectly the brand’s colors tie in, automotive toolboxes as desks, and the racing seat desk chairs? It seems like one of the most exciting rooms yet.

From there, we switched buildings over to Mishimoto’s 82,000 sq. ft. home in the quiet Delaware business park. I know what you’re thinking, and no, we didn’t use the bikes — but we should have. Before entering, we noticed an electric vehicle charging station positioned out front. It’s nice to see companies thinking ahead and adapting to the growing need for daily energy recharging.

Inside, we abided by Mishimoto’s — and its friendly penguin mascot, Chilly’s — policy of keeping two radiators’ distance apart as we absorbed the second facility’s details. The Accounting and Operations department employees warmly welcomed us upon entry. We noticed the much brighter tones of the same color scheme here before we proceeded. Mishimoto does a great job of promoting its brand identity in each space.

Distinct stages of the company’s history attached to the walls told the tale of each momentous occasion for Mishimoto, including different project car features immortalized into plaques and the artistic hood of a 350Z decorated entirely using a Sharpie marker!

An on-site gym helps employees fit exercise into their daily routine without having to time it accordingly on their way home from the office. The gym housed multiple forms of equipment from Peloton cardio machines to weight training, all at the employee’s disposal.

What I’d call the feel-good center is named the showroom. The excellently-branded breakroom features boldly written company core values, several fun game options, and a well-stocked kitchen area. However, this is not your ordinary breakroom. The company holds crucial group meetings on the projection screen, training sessions, parties, and happy hours. The vibes and atmosphere were palpable even without any employees occupying the space, making it clear why it was voted one of The News Journal’s Top Places to Work in 2016.

The automotive decor continues here as a massive tractor tire doubles as a stage, complete with waterjet-cut branding, and the trash cans find sanctuary inside a pile of tires for an undisputed continuation of the theme.

Outside the showroom and looking like somewhat of a Felipe Pantone mural, Mishi’s Customer Experience pod is situated inside the warehouse to get this talented team closer to the shipments they rely on to perform their duties. Some examples of bruised and battered Mishi products are each displayed with pride and a story within the pod — this one still holds pressure even after the crash in the photo, too!

We were now suited up in high-visibility jackets to tour the expanse of the Mishimoto product warehouse. Endless shelving not only houses all of the recently manufactured product but separates areas of the warehouse floor used for inbound and outbound shipments. The receiving section brings new loads of finished products in and organizes them for storage on the shelves or moves them directly outbound in the far reaches of the building.

Iconic orange cellophane wraps outbound freight shipments headed to any number of direct retailers, wholesale distribution centers, or other Mishimoto global locations (including Sparks, NV, London, and Sydney). And just like those stacks of innovative Mishimoto products, it was time we conclude our time in Delaware, as well.

We want to thank Ricky and the entire Mishimoto staff for opening their doors to us and displaying this unique company’s home. If you’re interested in learning more about the brand or its products, please use the links below.

Photography by Brandon Cody and Kyle Crawford

https://www.mishimoto.com/

https://www.facebook.com/GoMishimoto/

https://instagram.com/mishimoto/

https://www.youtube.com/Mishimoto

https://www.mishimoto.com/engineering/