- The Accusump accumulator plumbs into an engine’s oil system to prevent any pressure drops.

- A cost-effective way of providing more continuous oiling and protecting your engine at the track or on the street.

- Vibrant Performance stepped in with some high-quality fluid delivery solutions.

Engine oil is the lifeblood of any engine. It works by lubricating every part that moves and helps to fight against the three most prominent antagonists: heat, friction, and wear. A low engine oil level in the sump can be detrimental to longevity, primarily when caused by extra lateral Gs. This is a common engine failure for avid track racers, but did you know these same damaging effects can occur in street cars? Most engine wear occurs after cold starts because, initially, no oil is circulating to separate the moving parts. Even worse, when that same car has been sitting in storage, firing it up for the first time is when the real nightmare begins.

WHAT’S AN ACCUSUMP?

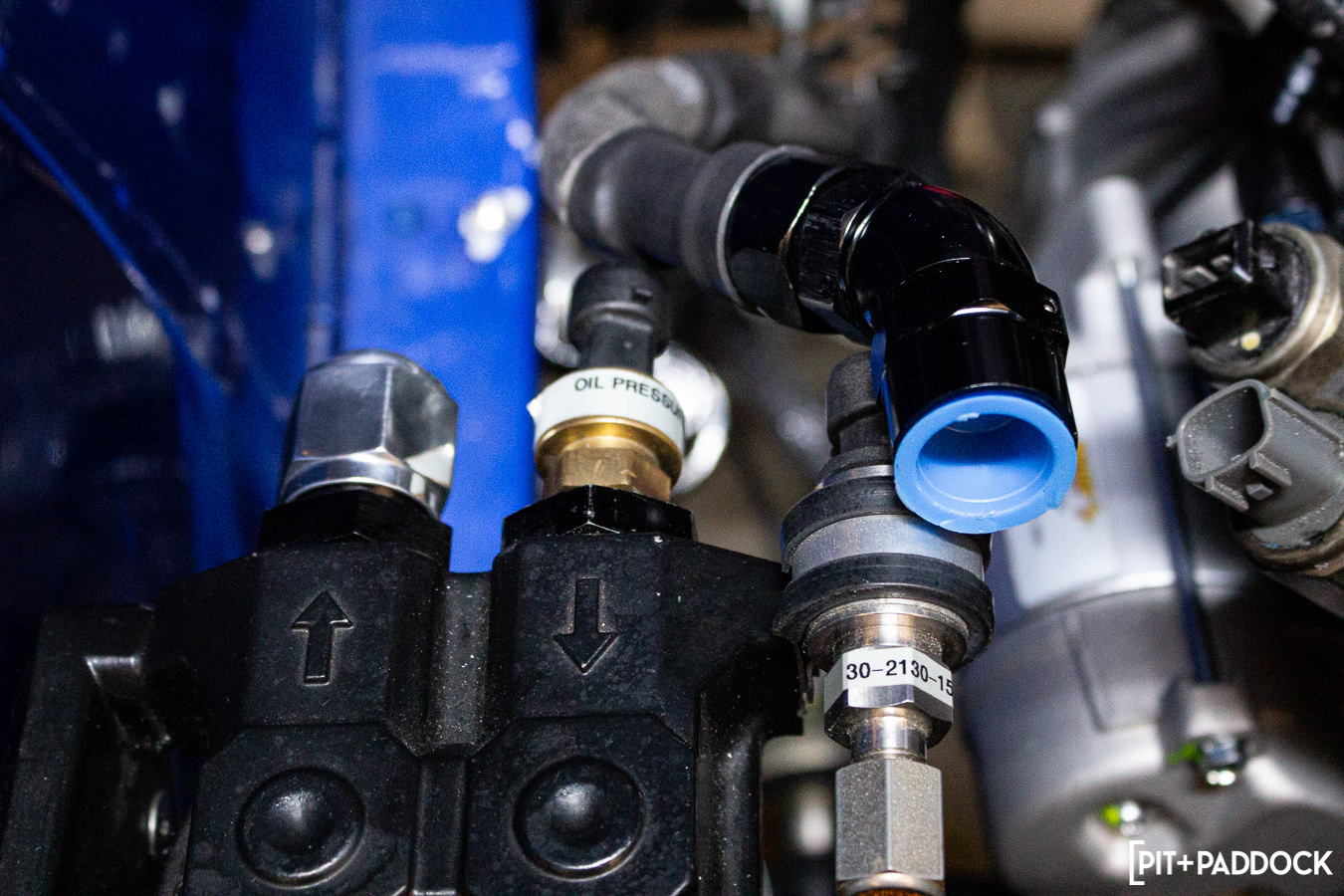

The Accusump provides an added layer of protection against costly engine repairs or replacement. Manufactured by Canton Racing Products, this automotive accumulator plumbs into an engine’s oil system to prevent pressure drops. Depending on how the system is set up, using an electronic solenoid can provide pre-start oiling and protect against “momentary” loss of oil pressure from the oil pump.

Depending on your oiling requirements, Accusump offers a manual type or electric valve that automatically opens to provide pre-oiling when the ignition is activated and closes to store pressurized oil when the engine shuts down.

HOW DOES IT WORK?

The accumulator uses a piston valve preloaded with air on one side of the valve, which moves the piston valve down the reservoir and pushes the oil into the oil system when required. This piston-style oil accumulator stores oil at pressure, ready to release when detecting pressure drops while providing oil pressure to the bearings before starting an engine.

ACCUSUMP INSTALLATION

Our initial three-quart Accusump setup mounted the unit closer to the fuel tank but posed issues. The initial problem was the Accusump’s proximity from which it sat, knowing hot engine oil would be circulating both to and from the unit. The second was the head-scratching dilemma on making room to clear the hose end fittings and oil line.

Following a series of repositioning, I decided to move the unit further back. I used the factory drain plug to add a -10AN bulkhead fitting and plumb a stainless-steel braided line to eliminate the need to cut into the chassis.

Problem solved? Not quite. Adequate clearance for the Accusump continued to pose an issue with the factory pressure gauge taking up precious space. For this install, every inch counted!

A quick rummage through my spare AN fittings parts container netted adapters and a smaller sized gauge to retrofit onto the unit.

OIL LINE SETUP

With the unit finally resting in the proper position and the billet brackets secured, it was time to begin plumbing the oil line to the engine. I punched out a metal plate to replace the drain plug and fitted it with a 90-degree bulkhead adapter and PTFE washers for a watertight seal.

I located a piece of leftover 90-degree hose end fitting and hose to use for a mockup to confirm adequate clearance. The mounting plate is rivet fastened into place following a quick coating of Steel-It. Notice the Vibrant Performance high flow hose end fitting’s design maintains proper fluid flow compared to the mockup fitting, which uses a more restrictive design.

This build has an assortment of Vibrant Performance AN fitting and -10AN PTFE lined steel braided hose line. Compared to rubber-lined hoses, PTFE-lined hoses are superior in every way. The smooth bore PTFE inner-tube offers a higher temperature tolerance, working pressure, and improved chemical resistance. The stainless steel high tensile braided cover provides reinforcement and added protection for the oil lines running under the vehicle.

To simplify the oil line assembly, I used a pair of Vibrant Performance braided hose cutters to slice through the stainless braided line. Before making the cut, I used electrical tape to help guide the area I cut to length while eliminating the steel braid from flaring out.

Investing in a set of aluminum wrenches is highly recommended when it comes time for assembly. These AN hose end-specific wrenches eliminate the chance of introducing any unsightly marring or gouging the anodized finish.

VIBRANT PERFORMANCE QUICK RELEASE FITTING

I installed a Vibrant Performance dry-break quick release fitting for easy disassembly by hand. Dry break or dry disconnect couplers are designed for quick and leak-free connection and disconnection. What are the advantages of a dry-break setup, you ask? Simply stated, it works by using an automatic mechanism to seal off both ends of the hoses when disconnected.

The Vibrant Performance fitting — constructed out of 6061 billet aluminum — uses a bayonet-style locking system. Stay tuned for future content as we detail these nifty fittings and their added benefits when addressing additional fluid-related components, including fuel, oil, and coolant.

The oil lines were securely fastened to the chassis using Vibrant Performance hose mounting clamps.

HEAT PROTECTION

DEI Fire Sleeve protects the entire length of the steel braided line and insulates heat away from the fuel lines. This material features elevated temperature-resistant braided glass material and is coated in silicone rubber.

ENGINE INSTALLATION

Professionally installing an Accusump unit into the engine’s oiling system prevents pressure drops while providing oil pressure to the bearings before starting an engine. I introduced the main unit into the engine’s oiling system for this install, which required tapping into one of the remaining remote oil filter adapter ports.

When using an Accusump for pre-lubricating, it is recommended to use an oil filter with a built-in anti-drain valve to prevent oil from flowing back to the sump via the oil pump.

When breaking in a fresh engine, Canton Racing recommends disabling the Accusump if equipped with an electric valve. Passages in the valve can clog with the assembly lube or foreign contaminant introduced into the cylinder.

ELECTRICAL WIRING

The last step consisted of wiring up the electric valve, and a toggle switch with a custom LED indicator to inform the driver when the valve is activating.

The Accusump is protected against damage and completely hidden in the spare tire mount but is still readily accessible. This setup not only offers a clean appearance but usable trunk space.

Accusump is a cost-effective way of providing more continuous oiling and adding longevity to protect your engine at the track or on the street. Don’t wait until catastrophic engine failure occurs. Make the smart choice by installing an Accusump system.