- 2021+ BMW M3/M4 models are known as the G80/G82 chassis.

- BMW G8X M models are powered by the S58 twin-turbo inline-six.

- Mishimoto’s performance air intake reduces intake restriction (up to 22.8%) for more power potential.

For decades, the BMW M division has consistently refined the benchmark premium sports car with the M3 (and now M4) nameplates. The most current generation, dubbed the G80 M3 and G82 M4, has been met with controversy as the German brand has pushed the envelope of not only performance but also the styling choices for the bodywork.

We’re not here to debate over the face only a mother could love, but rather what is beyond the gargantuan kidney grilles – the mighty S58 twin-turbo inline-six. More importantly, the air intake system and how our friends at Mishimoto engineered and developed a unique solution over the restrictive factory setup. Today, we’ll give you insight into the company’s process regarding researching and developing the product that should be on any G8X owner’s wish list.

ANALYZING THE FACTORY INTAKE SYSTEM

Let’s keep in mind that when auto manufacturers engineer components, they aren’t always looking for “the most powerful” or “most efficient” results. They have particular targets for specific pieces and a budget to do so. These parameters result in pieces like the intake system being packed into a tight space with restricted flow to help meet efficiency goals. Frequently, the construction materials are cheaper to keep the bottom line more profitable.

With the S58 being twin-turbocharged, BMW engineered independent intake systems for each turbo to better deliver air to each and maximize efficiency. However, like most things in our industry, there is room for improvement and oversights that the aftermarket can correct. The factory intake runners utilize ribbed joints to help them flex and move independently from the engine, but it leads to turbulence in the system and ultimately reduces airflow to the turbos. The airboxes have slightly different outlet sizes and house flat dry panel filters that are dense and restrict air.

NEXT-LEVEL TECH FOR NEXT-LEVEL SOLUTIONS

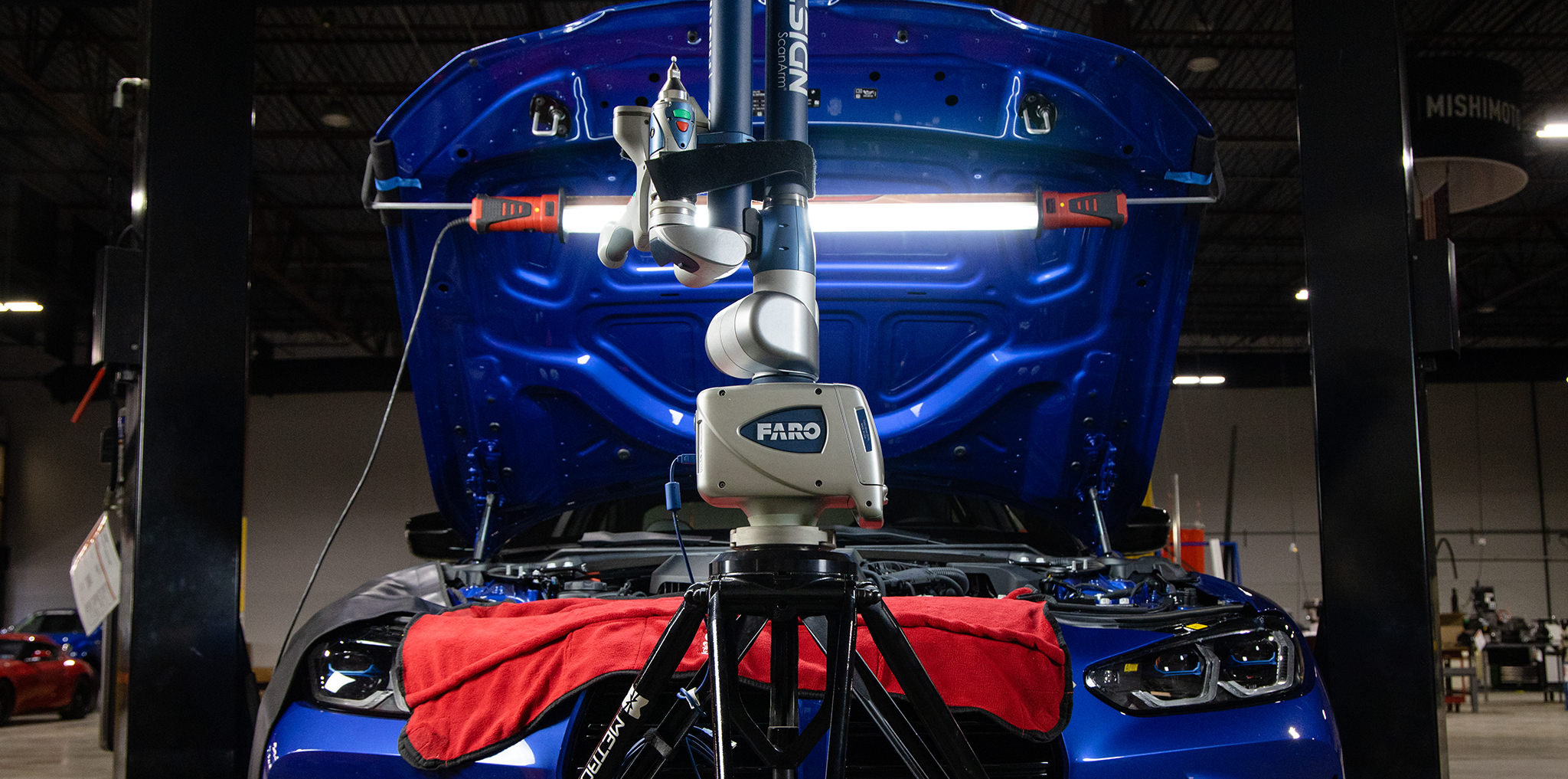

Mishimoto has a very talented team of engineers with tons of experience. That team is equipped with the latest technology to help produce the parts for which the aftermarket is hungry. After analyzing the factory intake system, the company’s engineers removed everything and used cutting-edge CAD programs to scan the engine bay. This process creates a digital workspace for the designers to interact with the engine while eliminating a lot of guesswork. From there, the OEM intakes are tested on the Mishimoto flow bench to collect data on how restrictive air flow might be.

The engineers take this data, workspace, and experience from previous intake concepts to create the new parts. Mishimoto has opted to use cross-linked polyethylene (XLPE) rotational-molded construction that allows for complex shapes and heat resistance. The first batch of prototypes was brought to fruition by Mishimoto’s 3D printers and underwent an annealing process to further protect from high engine temps. Finally, the turbo snout was created through selective laser sintering. This process uses a laser to cure nylon powder into a specific shape for even more precise tolerances. In the final step, once everything is tight and fits appropriately, the prototype heads to the flow bench to be measured against the restrictive OEM system.

GO WITH THE FLOW

The advanced flow bench Mishimoto uses allows air volume measurements to be taken from 100 to 300 cubic feet per minute (CFM), simulating the S58’s entire powerband. With the brand-new design, Mishimoto measured 13% less restriction in CFM on the driver’s side intake and 22.8% less on the passenger’s side intake. While both sides of the S58’s intake work to achieve the same goal, they still operate independently, and the data needed to be recorded as such.

The final test sees real work on Mishimoto’s Dynapacks for dyno testing, and the results produced precisely what the team was targeting. The ECU adjusted to compensate for the additional airflow to retain the same power output but with an improved induction soundtrack. While this intake system doesn’t directly increase power output, it does provide much more efficient air induction and allows for more significant gains with simple tuning.

MINOR CHANGES, MAJOR RESULTS

Sometimes the best strategy for aftermarket modifications is to refine rather than reinvent. The Mishimoto team saw a clear need to improve the BMW S58 air induction system and set out to provide a product that is high quality, easy to install, and optimizes airflow. The completed product does all that while enhancing induction noise to provide a fantastic first bolt-on for any M3/M4 owner. In today’s tuner market, many opportunities to upgrade go hand in hand with this intake. Whether an M3/M4 owner’s intentions are OEM+ or GT-R fighting power, this intake is a great starting point to enhance. After all, it’d be easier to explain how the G8X’s gaping grille is functional, right?